Carbide inserts are the workhorses of the metalworking world. These small, incredibly tough blades are used in lathe tools, milling machines, and other cutting applications to shape and refine metal. But with a vast array of brands and options on the market, choosing the right carbide insert can feel overwhelming.

This guide dives deep into Shars carbide inserts, a popular choice for hobbyists and professionals alike. We’ll explore the nitty-gritty of their production process, delve into the different types available, and equip you with the knowledge to select the perfect Shars insert for your next project.

Introduction to Shars Carbide Inserts

Imagine a tiny, super-strong chisel that can tear through metal like butter. That’s essentially what a Shars carbide insert is. Made from a super-hard material called tungsten carbide (think of it as the diamond of the metalworking world), these inserts are bonded to a steel shank, creating a durable and cost-effective cutting tool.

Shars offers a wide variety of carbide inserts catering to different needs. Whether you’re a seasoned machinist or a weekend warrior tinkering in your garage, there’s a Shars insert out there waiting to be unleashed on your metal project.

The Production Process of Shars Carbide Inserts

Have you ever wondered how these tiny titans of toughness are born? The production process of Shars carbide inserts is a fascinating dance between engineering and chemistry. Here’s a simplified breakdown:

- Powder Power: The journey begins with tungsten carbide powder, the magic ingredient that grants the insert its incredible strength. This powder is meticulously crafted to achieve the desired grain size and composition.

- Mixing and Matching: The carbide powder is then blended with various additives and binders, depending on the specific insert’s intended use. This concoction is what determines the insert’s properties like wear resistance and heat tolerance.

- Shaping Up: The mixed powder is pressed into the desired insert shape using a high-pressure molding process. Imagine a giant metal hand squeezing the mixture into the form of a tiny, precise blade.

- The Heat is On: Once shaped, the inserts are subjected to an intense sintering process. Think of it as baking a cake, but at temperatures exceeding 2,000 degrees Celsius! This high heat fuses the carbide particles together, creating a rock-solid structure.

- Sharpening Up: After cooling, the inserts are ground and honed to razor-sharpness. This ensures clean, precise cuts on your metal workpiece.

- Quality Check: No Shars insert hits the market without passing rigorous quality checks. These checks ensure the insert meets strict standards for size, shape, and overall performance.

The result of this intricate process is a Shars carbide insert – a small but mighty tool ready to tackle your metalworking challenges.

Selection of Shars Carbide Inserts

With a plethora of Shars carbide inserts available, selecting the right one can feel like picking a lock without the combo. But fear not, metalworking warriors! Here’s a breakdown of the key factors to consider:

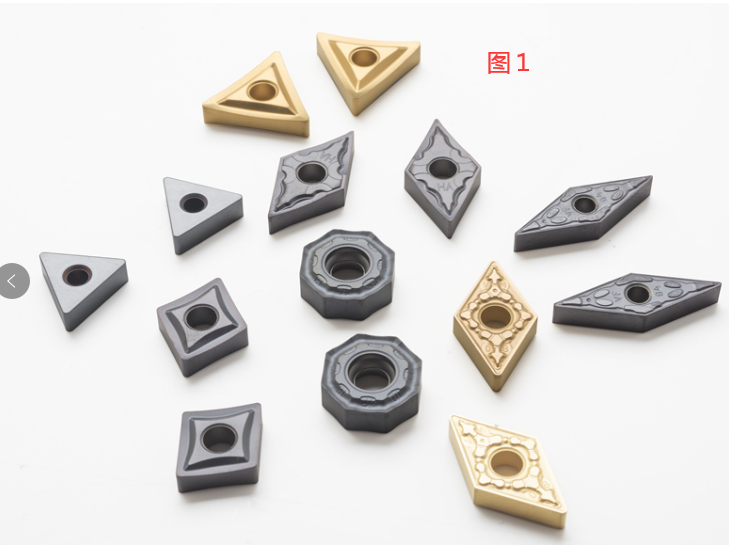

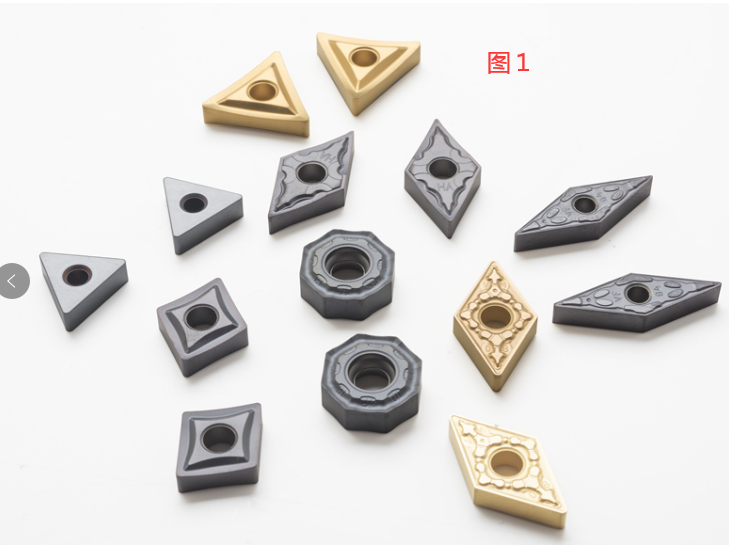

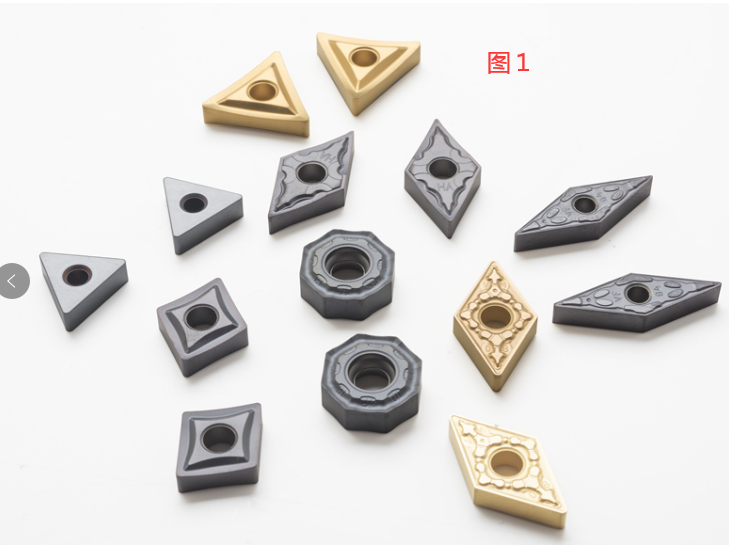

- Insert Geometry: The insert’s geometry, or shape, plays a crucial role in how it interacts with the metal. Common geometries include triangular, square, and round inserts, each designed for specific cutting applications. For example, triangular inserts excel in roughing cuts, while round inserts are ideal for finishing cuts.

- Insert Grade: Shars offers various insert grades, which refer to the specific carbide composition and coating used. Each grade caters to different materials and cutting conditions. For instance, a grade optimized for stainless steel might not perform as well on hardened steel.

- Application: What kind of metal are you cutting? What type of cut are you making (roughing, finishing, threading)? Understanding your application is key to selecting the most suitable Shars insert.

- Shank Compatibility: Shars inserts are designed to fit specific toolholder shanks. Ensure the insert’s shank type (e. g., CCMT, TNMG) matches your lathe or milling machine’s toolholder.

By considering these factors, you’ll be well on your way to selecting the Shars carbide insert that will help you achieve clean, efficient, and professional-looking metal cuts.

Here’s a helpful analogy: Think of Shars carbide inserts as paint brushes. You wouldn’t use the same brush for delicate watercoloring as you would for applying thick house paint. Similarly, the right Shars insert acts as the perfect brush for your specific metalworking project.

Shars Carbide Inserts

Shars offers a comprehensive selection of carbide inserts to suit various applications. Here’s a glimpse into some of their popular offerings:

- Turning Inserts:

- CCMT Series: A versatile workhorse, the CCMT series is designed for turning applications. These triangular inserts come in various grades, making them suitable for machining steel, stainless steel, aluminum, and even cast iron. Their positive rake angles allow for smooth cutting and efficient chip evacuation.

- CNMG Series: Need a champion for roughing cuts? Look no further than the CNMG series. These inserts boast thicker geometries and stronger cutting edges, ideal for removing large chunks of material quickly. They’re available in grades specifically formulated to handle the rigors of heavy-duty cutting.

- Milling Inserts:

- APKT Series: The APKT series reigns supreme in face milling applications. These square inserts feature sharp cutting edges and a positive rake angle, ensuring clean and efficient material removal across the entire workpiece surface.

- SEET Series: Conquering corners is the specialty of the SEET series. These inserts are designed for shoulder milling and slotting, where precise cuts and sharp corners are essential. Their intricate geometries allow for clean and accurate profiling of your metal workpiece.

- Threading Inserts:

- VGGR Series: When it comes to threading, the VGGR series takes center stage. These inserts boast specialized geometries that precisely form clean and accurate threads on your metal components. They’re available in various thread profiles, ensuring you have the right tool for the job.

- Brazing Inserts:

- BT Series: For those working with softer metals like aluminum and plastics, the BT series is a perfect choice. These brazing inserts are designed to be brazed onto a toolholder, creating a durable and cost-effective cutting tool.

This is just a sampling of the vast Shars carbide insert selection. By exploring their offerings and considering the factors mentioned earlier, you’ll be equipped to find the ideal insert for your specific metalworking needs.

Shars Carbide Inserts vs. The Competition

While Shars carbide inserts have carved a niche for themselves in the metalworking world, they aren’t the only contenders in the arena. Let’s take a peek at how Shars stacks up against some of the other big names:

- Sandvik Coromant: A titan of the industry, Sandvik Coromant is renowned for its premium-grade inserts known for exceptional wear resistance and cutting performance. However, this top-tier quality often comes at a premium price.

- Kennametal: Another industry leader, Kennametal offers a wide range of high-performance inserts that rival Sandvik Coromant. Similar to Sandvik Coromant, Kennametal inserts tend to be on the pricier side.

- Iscar: Offering a balance between quality and affordability, Iscar is a popular choice for many metalworkers. Their inserts provide good performance at a more competitive price point compared to Sandvik Coromant and Kennametal.

So, how do Shars carbide inserts fare in this metalworking battle royale?

Shars shines with its cost-effectiveness. They offer high-quality inserts at a price point that’s attractive to hobbyists and budget-conscious professionals alike. While they might not reach the absolute peak performance of Sandvik Coromant or Kennametal, Shars inserts deliver excellent value for the price.

Here’s an analogy: Think of Shars carbide inserts as the “rising star” of the metalworking world. They might not be household names yet, but they’re rapidly gaining recognition for their quality and affordability.

The Advantages of Using Shars Carbide Inserts

- Cost-Effective: As mentioned earlier, a key advantage of Shars carbide inserts is their affordability. Compared to some premium brands, Shars offers excellent value, making them a great choice for those working on a budget.

- Variety of Options: Shars boasts a diverse selection of inserts catering to various applications. Whether you’re turning, milling, threading, or brazing, there’s a Shars insert waiting to tackle your project.

- Decent Performance: While not the absolute top tier, Shars carbide inserts deliver good performance for most metalworking applications. Hobbyists and even professionals can achieve clean and efficient cuts with Shars inserts.

- Widely Available: Shars carbide inserts are readily available online and in many physical tool stores. This easy access makes it convenient to get the inserts you need for your project.

Potential Disadvantages of Shars Carbide Inserts

- Not the Absolute Best: There’s a reason why some premium brands command higher prices. Sandvik Coromant and Kennametal inserts might offer slightly superior wear resistance and cutting performance in specific applications.

- Limited Brand Recognition: Compared to established players like Sandvik Coromant and Kennametal, Shars might not have the same level of brand recognition. This can lead to some skepticism among users unfamiliar with the brand.

- Inconsistent Quality (Potential Issue): While Shars strives for quality control, there have been occasional reports of inconsistencies in insert quality. It’s advisable to purchase from reputable Shars distributors to minimize this risk.

Finding the Right Balance:

Ultimately, the decision of whether Shars carbide inserts are right for you depends on your individual needs and priorities. Here’s a breakdown to help you decide:

- For Hobbyists and Budget-Conscious Professionals: If you’re a hobbyist or a professional working on a tight budget, Shars carbide inserts are a fantastic option. They offer excellent value for the price and will enable you to tackle most metalworking projects effectively.

- For Professionals Demanding Top-Tier Performance: If you’re a professional machinist working on high-precision projects or dealing with exceptionally hard materials, you might consider premium brands like Sandvik Coromant or Kennametal. These inserts might provide that extra edge in terms of wear resistance and cutting performance.

Remember: There’s no single “best” brand when it comes to carbide inserts. The ideal choice depends on your specific needs, budget, and the type of metalworking you do.

Sharpening Your Skills with Helpful Tips

Now that you’re armed with knowledge about Shars carbide inserts, here are some practical tips to help you get the most out of them:

- Start with the Right Insert: As emphasized earlier, selecting the correct Shars carbide insert for your application is crucial. Consider the type of metal you’re cutting, the cut you’re making, and your machine’s compatibility.

- Sharpen Your Technique: Even the best inserts won’t perform optimally if your cutting technique is off. Invest some time in learning proper machining techniques for the specific operation you’re performing.

- Cool It Down: Metal cutting generates a lot of heat. Using a coolant can significantly extend the life of your Shars carbide insert and improve the quality of your cuts.

- Listen to Your Machine: Pay attention to the sound of your machine while cutting. If you hear unusual noises or vibrations, it might indicate that your insert is dull or needs replacing.

- Store them Right: When not in use, store your Shars carbide inserts properly in their designated holders or packaging. This will help prevent chipping or damage.

By following these tips and choosing the appropriate Shars carbide inserts, you’ll be well on your way to achieving professional-looking metalworking results.

FAQ

Table 1: Frequently Asked Questions (FAQ) about Shars Carbide Inserts

| Question | Answer |

|---|---|

| What are Shars carbide inserts made of? | Shars carbide inserts are typically made from tungsten carbide, a very hard and wear-resistant material. |

| Are Shars carbide inserts good? | Shars carbide inserts offer a good balance between affordability and performance. They are a great choice for hobbyists and budget-conscious professionals. |

| How do I choose the right Shars carbide insert? | Consider the type of metal you’re cutting, the cut you’re making (roughing, finishing, threading), and your machine’s compatibility when selecting a Shars carbide insert. |

| Are Shars carbide inserts better than Sandvik Coromant or Kennametal inserts? | Sandvik Coromant and Kennametal inserts might offer slightly superior wear resistance and cutting performance in specific applications, but they also come at a higher price. Shars inserts provide excellent value for most metalworking needs. |

| Where can I buy Shars carbide inserts? | Shars carbide inserts are available online and in many physical tool stores. |