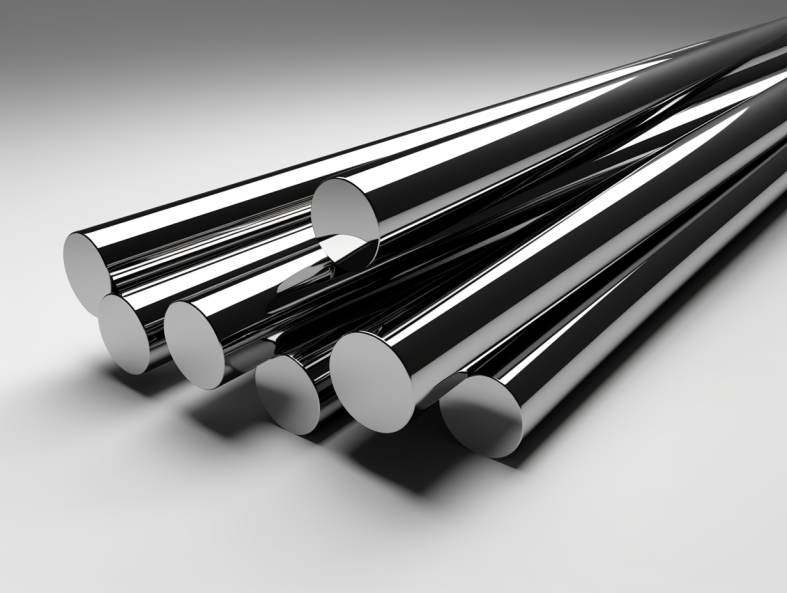

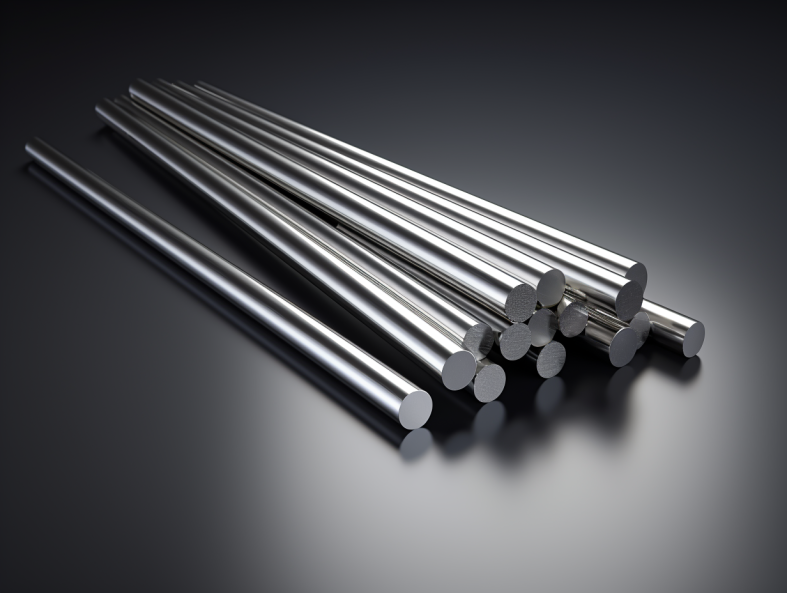

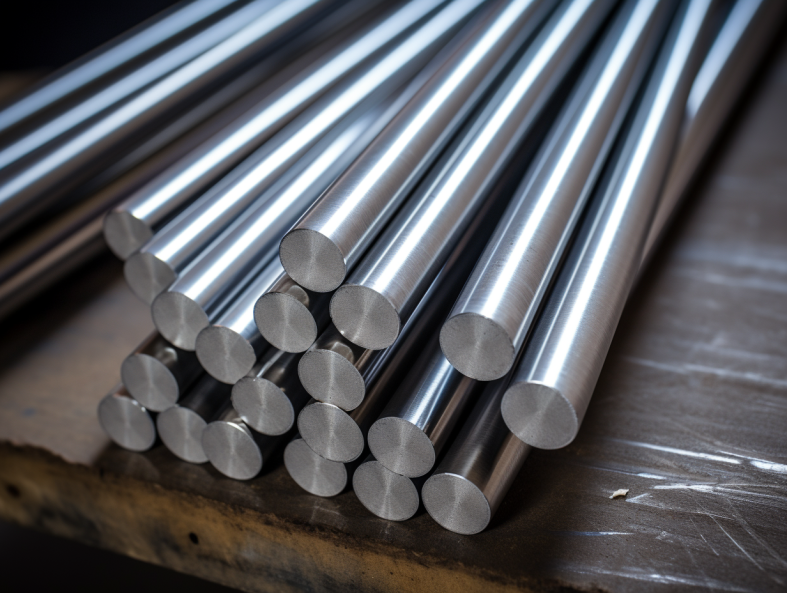

Solid Carbide Rods

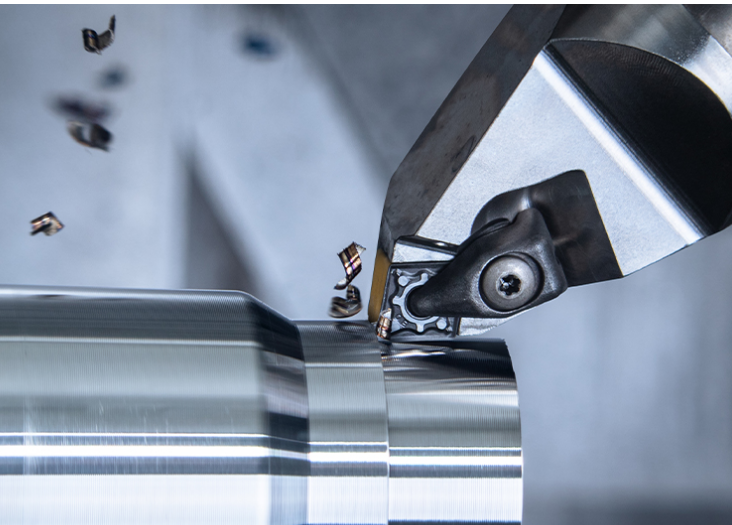

Solid carbide rods are a game-changer in industries that demand durability, precision, and efficiency in cutting tools, automotive components, and specialized manufacturing equipment. Known for their resilience, hardness, and wear resistance, solid carbide rods come in various grades and compositions