Imagine this: you’ve meticulously selected the perfect wood for your project, a piece of mahogany with a rich, deep grain that begs to be brought to life. You feed it through your trusty wood planer, expecting that signature smooth finish, but instead, you’re met with chatter marks and uneven cuts. Frustration sets in – what went wrong? The culprit might be dull or damaged planer blades. But fear not, woodworker warrior, for there’s a solution that’s as sharp as it is ingenious: wood planer carbide inserts.

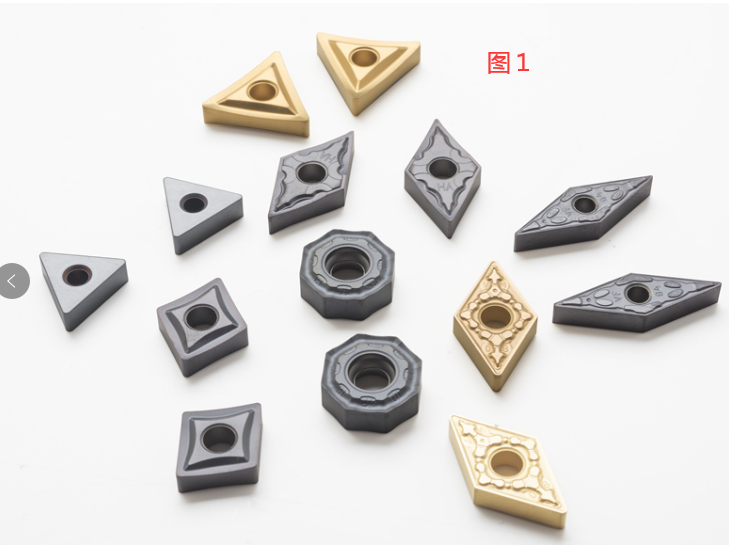

What are Wood Planer Carbide Inserts?

Wood planer carbide inserts are like tiny knights in shining armor for your planer blades. Crafted from incredibly hard and wear-resistant tungsten carbide – a metal alloy even diamonds would envy – these inserts are embedded into the body of your planer blades. When a cutting edge gets dull, you simply rotate the insert, revealing a fresh, sharp edge ready to tackle even the toughest hardwoods.

The Advantages of Wood Planer Carbide Inserts

- Sharper Cuts, Longer Life: Compared to traditional high-speed steel (HSS) planer blades, carbide inserts stay sharper for significantly longer. This translates to cleaner cuts with less tear-out, especially for hardwoods and figured wood. Think of the difference between using a brand new razor and a week-old one – that’s the level of sharpness you can expect.

- Reduced Downtime: With multiple cutting edges on each insert, you can simply rotate them when one edge gets dull. This eliminates the need for frequent sharpening, saving you valuable time and keeping your workflow smooth. Imagine spending less time fiddling with blades and more time crafting beautiful pieces.

- Cost-Effective in the Long Run: While the initial cost of carbide inserts might be higher than HSS blades, their extended lifespan and reduced sharpening needs make them a cost-effective choice in the long run. It’s like investing in a high-quality pair of work boots – they might cost more upfront, but they’ll last you much longer than cheaper alternatives.

- Improved Finish Quality: The superior sharpness of carbide inserts translates to a smoother, more professional-looking finish on your woodworking projects. This is especially crucial for furniture pieces or projects where a flawless finish is paramount.

- Versatility: Carbide inserts come in a variety of sizes and grades to suit different planer models and woodworking applications. So, whether you’re a hobbyist with a benchtop planer or a professional running a production shop, there’s a carbide insert out there for you.

Disadvantages of Wood Planer Carbide Inserts

- Higher Initial Cost: As mentioned earlier, carbide inserts typically have a higher initial cost compared to HSS blades. However, as discussed, their extended lifespan and reduced sharpening needs can offset this cost over time.

- Chipping Potential: While incredibly hard, carbide inserts can chip if they encounter foreign objects like nails or screws hidden within the wood. However, this risk can be mitigated by using a metal detector on your lumber before feeding it through the planer.

- Learning Curve: Installing and rotating carbide inserts might require a bit of practice compared to simply replacing a dull HSS blade. However, most planer manufacturers provide clear instructions, and with a little practice, it becomes a quick and easy process.

The Application of Wood Planer Carbide Inserts

Wood planer carbide inserts are a fantastic choice for a wide range of woodworking applications, including:

- Surfacing rough lumber: When you need to achieve a perfectly flat surface on rough lumber, carbide inserts will make the job a breeze.

- Dimensioning lumber: Ensuring accurate and consistent thicknesses for your woodworking projects is crucial, and carbide inserts provide the precision and longevity needed for this task.

- Jointing edges: Creating perfectly square and straight edges for flawless glue-ups becomes much easier with the sharp, consistent cuts offered by carbide inserts.

- Planing hardwoods and figured wood: Hardwoods and figured wood can be notoriously difficult to work with. Carbide inserts provide the extra edge (pun intended) needed to achieve clean cuts without tear-out.

- Creating moldings and other profiles: For projects that require intricate profiles, carbide inserts offer the control and precision needed to execute even the most detailed cuts.

Types, Composition, Properties, and Characteristics of Wood Planer Carbide Inserts

Here’s a table outlining the key details of various wood planer carbide insert types:

| Type | Composition | Properties | Characteristics |

|---|---|---|---|

| Microcrystalline Carbide (K Grades) | Tungsten Carbide with a finer grain structure | Excellent wear resistance, good toughness | Ideal for general woodworking applications, particularly suitable for hardwoods |

| Submicron Carbide (H Grades) | Tungsten Carbide with an even finer grain structure | Exceptional wear resistance, slightly less tough compared to K grades | Perfect for high-production environments and extended use with hardwoods and abrasive materials |

| Ceramic-Coated Carbide (CC Grades) | Tungsten Carbide core with a ceramic coating | Excellent wear resistance, high heat resistance | Ideal for heavy-duty applications and working with oily or resinous woods |

| Amorphous Diamond-Coated Carbide (AD Grades) | Tungsten Carbide core with an amorphous diamond coating | Unematched wear resistance, superior heat resistance | Best for industrial applications and working with the toughest and most abrasive materials |

Wood Planer Carbide Insert Specifications, Sizes, Grades, and Standards

Here’s a table outlining the common specifications, sizes, grades, and standards for wood planer carbide inserts:

| Specification | Description | Details |

|---|---|---|

| Size | Length (mm) x Width (mm) x Thickness (mm) | Varies depending on planer model. Common sizes include 12.7 x 12.7 x 1.5 mm, 14.3 x 14.3 x 2.0 mm, and 16 x 16 x 3.0 mm |

| Grade | Material composition and properties | K, H, CC, and AD grades as described previously |

| Number of Cutting Edges | Number of usable edges per insert | Typically 2, 3, or 4 cutting edges per insert |

| Standards | Industry standards for insert dimensions and compatibility | ISO (International Organization for Standardization) standards are common |

Suppliers and Pricing Details of Wood Planer Carbide Inserts

Here’s a table providing a general idea of suppliers and pricing for wood planer carbide inserts:

| Supplier | Type | Price Range (USD) |

|---|---|---|

| Grizzly | K Grade, 100 pack | $150 – $200 |

| Rikon | H Grade, 10 pack | $75 – $100 |

| Whiteside | CC Grade, 5 pack | $50 – $75 |

| Freud | AD Grade, 2 pack | $30 – $50 |

Please note: These prices are estimates and can vary depending on the specific size, grade, quantity, and retailer.

Comparing Pros and Cons of Wood Planer Carbide Inserts

| Pros | Cons |

|---|---|

| Sharper cuts and longer lifespan | Higher initial cost |

| Reduced downtime for sharpening | Potential for chipping if foreign objects are encountered |

| Cost-effective in the long run | Requires a slight learning curve for installation and rotation |

| Improved finish quality | |

| Versatility for different applications |

FAQ

Q: How often should I rotate my carbide inserts?

A: The rotation frequency depends on the type of wood you’re working with and the amount of use your planer sees. Generally, for hardwoods and frequent use, rotating after every 8-10 hours of planing time is a good rule of thumb. Softer woods might allow for longer intervals between rotations. Inspect your inserts regularly for signs of dullness or chipping.

Q: Can I sharpen carbide inserts?

A: While sharpening carbide is technically possible, it requires specialized equipment and expertise. In most cases, it’s more cost-effective to simply rotate or replace the inserts.

Q: How do I choose the right carbide insert grade for my needs?

A: For general woodworking and hobbyist use, K or H grades are a good starting point. If you work with hardwoods or abrasive materials frequently, consider H or CC grades. AD grades are best suited for industrial applications and the toughest materials.

Q: Where can I find replacement carbide inserts for my planer?

A: You can find carbide inserts from the planer manufacturer, online retailers like Amazon or Grizzly, or woodworking specialty stores.

In Conclusion

Wood planer carbide inserts are a valuable investment for any woodworker who desires superior cutting performance, efficiency, and extended blade life. By understanding the types, properties, and applications of carbide inserts, you can make an informed decision that elevates your woodworking experience and the quality of your projects. So, ditch the frustration of dull blades and embrace the sharp, precise cuts that carbide inserts deliver.