In the realm of metalworking, precision and efficiency reign supreme. That’s where Tungaloy carbide inserts come in, acting as the unsung heroes on your lathe or milling machine. These remarkable inserts are crafted from tungsten carbide, a ferociously hard material that laughs in the face of wear and tear. But what exactly are they, and how can they elevate your metalworking game? Buckle up, for we’re about to delve into the fascinating world of Tungaloy carbide inserts.

Introduction to Tungaloy Carbide Inserts

Imagine a tiny, replaceable blade specifically designed to conquer the toughest metals. That’s the essence of a Tungaloy carbide insert. These inserts are secured onto a toolholder, essentially transforming it into a cutting tool capable of facing down a variety of materials. Here’s the beauty: when the insert’s cutting edge dulls, you simply swap it out for a fresh one, keeping your downtime minimal and your productivity soaring.

Tungaloy, a renowned name in the cutting tool industry, has perfected the art of carbide insert creation. Their inserts boast exceptional hardness, translating to cleaner cuts, longer tool life, and ultimately, a reduction in your overall machining costs. But Tungaloy doesn’t stop there. They offer a staggering array of insert grades and geometries, each meticulously engineered to excel in specific machining applications.

The Production Process of Tungaloy Carbide Inserts

The journey of a Tungaloy carbide insert begins with meticulously crafted tungsten carbide powder. This powder, akin to a metal superhero in its raw form, is meticulously blended with other elements to achieve the desired properties for the final insert. The exact composition is a closely guarded secret by Tungaloy, a testament to their commitment to innovation and performance.

Next, the concoction is compacted under immense pressure, shaping it into the desired insert geometry. This shaping process is akin to molding clay, but on an industrial scale and with far more pressure involved. The result? A near-net-shaped form that closely resembles the final insert.

Now comes the magic: sintering. Imagine subjecting the compacted form to scorching temperatures, causing the particles to fuse into a solid, unified whole. This sintering process is what imbues the insert with its incredible strength and wear resistance.

The final step involves grinding the insert to its precise geometry and applying a special coating (if required). This coating serves as an additional layer of protection, further enhancing the insert’s performance and lifespan.

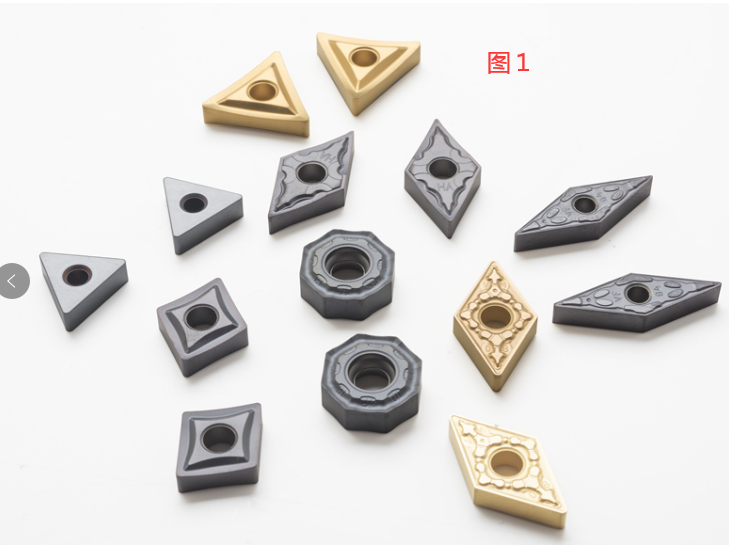

Types of Tungaloy Carbide Inserts

Tungaloy’s impressive arsenal boasts a diverse range of carbide insert types, each catering to specific machining needs. Here’s a glimpse into their most prominent offerings:

- Turning Inserts: These inserts are the workhorses of the lathe world, responsible for shaping and creating cylindrical parts. Tungaloy offers a wide variety of turning insert geometries, including nose radii, cutting edge angles, and chipbreaker designs, to tackle various turning operations with finesse.

- Milling Inserts: Milling involves shaping complex contours on workpieces. Tungaloy’s milling inserts, available in an array of shapes and sizes, are designed to conquer intricate milling tasks with remarkable precision.

- Grooving and Threading Inserts: Need to create precise grooves or threads? Tungaloy’s dedicated grooving and threading inserts cater to these specific requirements, ensuring clean and accurate results.

- Boring Inserts: Boring involves enlarging existing holes on a workpiece. Tungaloy’s boring inserts are engineered for exceptional hole concentricity and surface finish.

Selecting the Right Tungaloy Carbide Insert

With a plethora of Tungaloy carbide inserts at your disposal, choosing the right one can feel like navigating a labyrinth. Fear not, for a few key factors can guide you towards the perfect match:

- Workpiece Material: Different materials have distinct cutting requirements. Tungaloy offers inserts specifically designed for steel, stainless steel, aluminum, cast iron, and exotic materials, ensuring optimal performance for each job.

- Machining Operation: As discussed earlier, the type of machining operation (turning, milling, grooving, etc.) will dictate the insert geometry you need.

- Cutting Parameters: Factors like cutting speed, feed rate, and depth of cut influence insert selection. Tungaloy provides detailed recommendations for each insert grade, helping you dial in the ideal machining parameters for exceptional results.

Here’s an analogy: Imagine selecting the right paintbrush for your masterpiece. A coarse brush wouldn’t do justice to delicate details, just as a fine brush wouldn’t be ideal for broad strokes.

the Advantages Tungaloy Carbide Inserts

So, why should Tungaloy carbide inserts be your go-to choice? Let’s explore the compelling advantages they offer:

- Unmatched Wear Resistance: Tungsten carbide’s inherent hardness translates to inserts that stay sharp longer, significantly reducing downtime for insert changes. This translates to more parts machined per insert, ultimately lowering your machining costs.

- Superior Cutting Performance: Tungaloy’s inserts deliver clean, precise cuts, minimizing the need for rework and ensuring exceptional surface finishes on your workpieces. Imagine the difference between using a dull butter knife and a razor-sharp chef’s knife – that’s the level of cutting performance you can expect from Tungaloy inserts.

- Enhanced Productivity: Reduced downtime, faster cutting speeds, and fewer rejects all contribute to a significant boost in your overall machining productivity. With Tungaloy inserts, you can churn out parts at a faster clip, keeping your projects on schedule.

- Versatility Galore: As discussed earlier, Tungaloy’s diverse range of insert types, grades, and geometries caters to a vast array of machining applications. Whether you’re turning, milling, grooving, threading, or boring, there’s a Tungaloy insert that’s perfectly suited for the task.

- Cost-Effectiveness: While the initial cost of Tungaloy inserts might seem higher compared to less durable alternatives, their extended lifespan and ability to produce high-quality parts with minimal rework translate to significant cost savings in the long run. They’re an investment that pays off handsomely over time.

Considerations and Potential Drawbacks

While Tungaloy carbide inserts excel in many ways, it’s important to acknowledge some considerations:

- Higher Initial Cost: As mentioned earlier, the upfront cost of Tungaloy inserts might be slightly higher than some competing options. However, as discussed in the advantages section, their extended lifespan and superior performance often outweigh this initial cost.

- Choosing the Right Insert: With such a wide variety of inserts available, selecting the perfect one requires careful consideration of factors like workpiece material, machining operation, and cutting parameters. Tungaloy’s resources and support can be invaluable in navigating this selection process.

- Fragility: While incredibly hard, carbide inserts can be chipped or fractured if mishandled or subjected to excessive force. Proper handling and machining techniques are essential to maximize insert life.

By understanding these considerations and leveraging Tungaloy’s expertise, you can ensure that these inserts become a valuable asset in your metalworking arsenal.

FAQ

Here’s a breakdown of some frequently asked questions regarding Tungaloy carbide inserts, presented in a clear table format for your convenience:

| Question | Answer |

|---|---|

| What are the benefits of using Tungaloy carbide inserts? | Exceptional wear resistance, superior cutting performance, enhanced productivity, versatility, and cost-effectiveness in the long run. |

| How do I choose the right Tungaloy carbide insert for my application? | Consider factors like workpiece material, machining operation (turning, milling, etc.), and cutting parameters (speed, feed, depth of cut). Consult Tungaloy’s resources or contact their support team for guidance. |

| Are Tungaloy carbide inserts expensive? | The initial cost might be slightly higher than some alternatives. However, their extended lifespan and ability to produce high-quality parts often outweigh this cost. |

| How long do Tungaloy carbide inserts last? | Insert life depends on various factors like workpiece material, cutting parameters, and machining conditions. However, Tungaloy inserts are renowned for their extended lifespan compared to less durable options. |

| Where can I buy Tungaloy carbide inserts? | Tungaloy inserts are available through a network of authorized distributors worldwide. You can find a distributor near you on Tungaloy’s website. |

Conclusion

Tungaloy carbide inserts represent a powerful upgrade for your metalworking endeavors. Their exceptional wear resistance, superior cutting performance, and versatility make them a compelling choice for machinists of all skill levels. By understanding their advantages, considerations, and how to select the right insert for the job, you can unlock a new level of efficiency and precision in your metalworking projects. So, if you’re looking to elevate your machining game, consider incorporating Tungaloy carbide inserts into your toolbox. They might just become your new secret weapon for achieving metalworking mastery.