The Essential Role of Tungsten Carbide Blanks in the Automotive Industry:Driving Durability

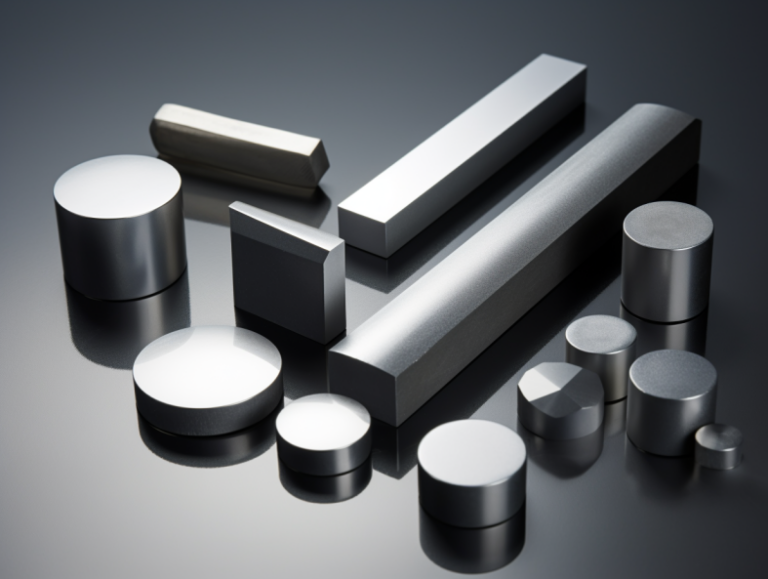

Enter tungsten carbide blanks – incredibly hard, wear-resistant components that form the foundation for a wide range of critical automotive parts.

Enter tungsten carbide blanks – incredibly hard, wear-resistant components that form the foundation for a wide range of critical automotive parts.

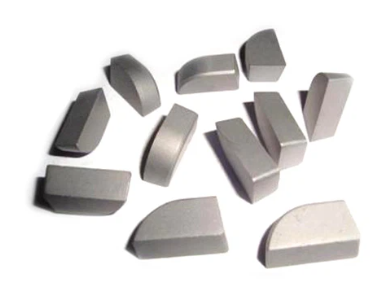

This principle holds particularly true for carbide block blanks, the robust foundation upon which countless industrial applications are built.

Customizable carbide blank dimensions offer manufacturers the ultimate flexibility to create tools and parts tailored to their exact specifications.

Enter corrosion-resistant carbide tube blanks – the unsung heroes engineered to withstand the toughest challenges and deliver uncompromising performance.

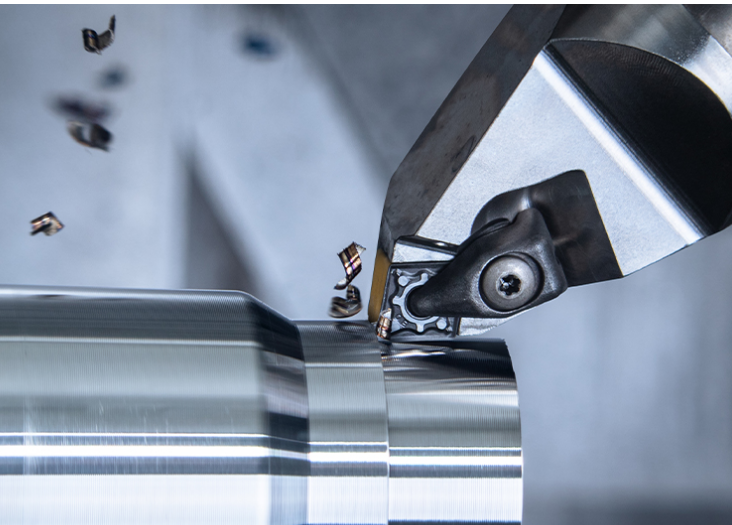

While carbide insert blanks are renowned for their hardness and wear resistance, it's the application of advanced coatings that truly unlocks their full potential.

Hardmetal carbide preforms are indispensable in various industries due to their exceptional hardness, wear resistance, and versatility.

In industries where abrasion, impact, and extreme conditions are daily challenges, wear-resistant carbide plate blanks emerge as unsung heroes.

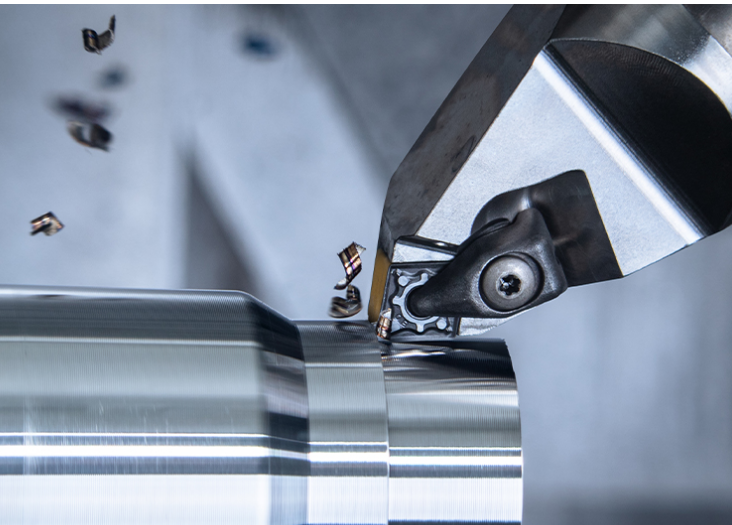

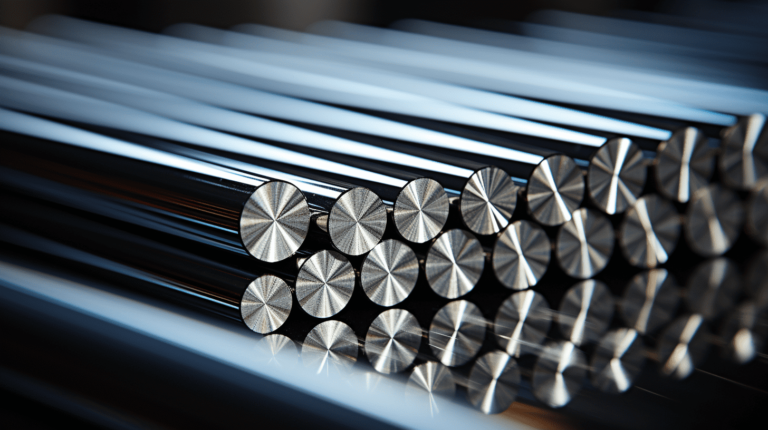

In the realm of high-precision manufacturing, where tolerances are tight and performance expectations are paramount, precision carbide rod blanks reign supreme.

Enter cemented carbide blanks, the unsung heroes behind countless cutting-edge tools and wear-resistant components.

High-quality tungsten carbide blanks are indispensable in various industries due to their exceptional hardness, durability, and versatility.