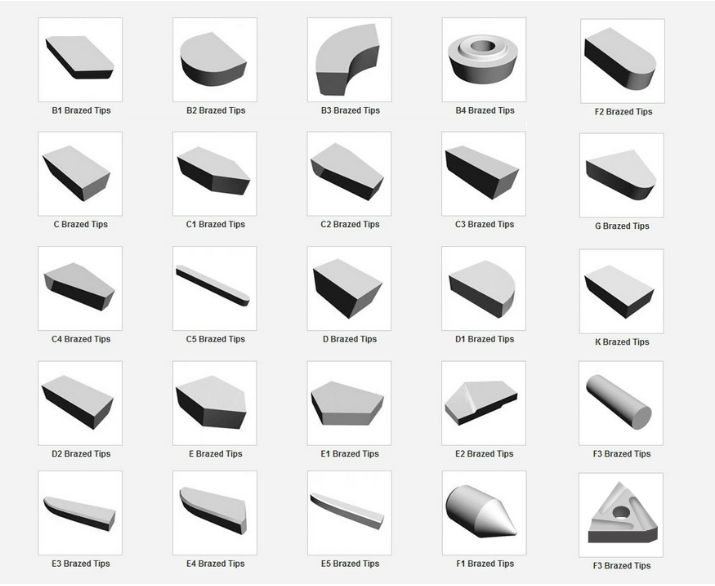

How the Geometry and Design of a Carbide Brazed Tip Affect Its Cutting Performance:Unlocking Superior Performance

In the world of machining and cutting tools, the geometry and design of carbide brazed tips play a crucial role in determining their cutting performance.