Carbide brazed tips are the unsung heroes of the machining world, offering unmatched durability and precision. Among the various types, Type A carbide brazed tips stand out for their unique geometry and design, which significantly enhance cutting performance. This article explores the fascinating world of Type A carbide brazed tips, delving into their geometry, design, and how these characteristics impact their cutting efficiency.

Introduction to Type A Carbide Brazed Tips

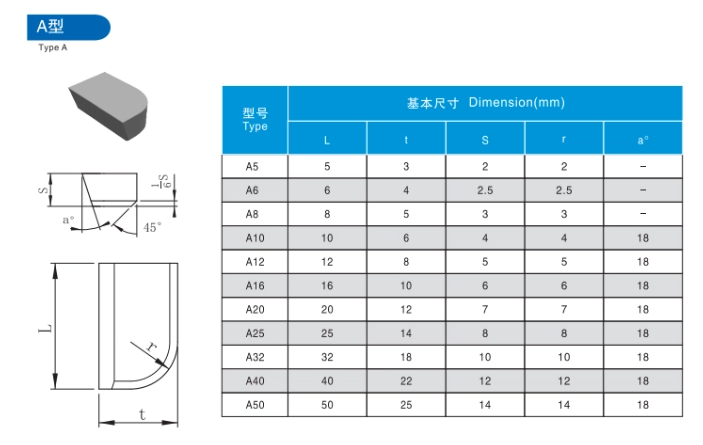

Type A carbide brazed tips are designed with specific geometric parameters that make them suitable for a wide range of cutting applications. Their unique design features allow them to perform exceptionally well under various machining conditions, making them a popular choice in the industry.

Key Features of Type A Carbide Brazed Tips

1. Geometry

The geometry of Type A carbide brazed tips is meticulously crafted to balance cutting efficiency and tool strength. Key geometric features include:

- Positive Rake Angle: Enhances chip formation and reduces cutting forces.

- Optimal Relief Angle: Prevents friction and heat buildup, improving cutting efficiency.

- Sharp Cutting Edge: Provides precise cuts and excellent surface finish.

- Ideal Corner Radius: Balances cutting forces and surface finish quality.

2. Design

The design of Type A carbide brazed tips incorporates several innovative elements to enhance performance:

- Chip Breakers: Integrated chip breakers control chip flow and prevent clogging.

- Durable Coatings: Advanced coatings such as TiN and AlTiN reduce friction and increase wear resistance.

- Robust Construction: The overall design ensures durability and resistance to breakage under high-stress conditions.

Impact of Geometry and Design on Cutting Performance

The geometry and design of Type A carbide brazed tips directly influence several critical aspects of cutting performance:

1. Cutting Efficiency

- Positive Rake Angle: Reduces cutting forces, making the cutting process more efficient.

- Optimal Relief Angle: Minimizes friction and heat, enhancing cutting performance.

2. Tool Life

- Sharp Cutting Edge: Maintains precision and reduces wear, extending tool life.

- Durable Coatings: Protects the tool from wear and heat, further extending its lifespan.

3. Surface Finish

- Sharp Cutting Edge: Provides clean, precise cuts, resulting in excellent surface finish.

- Ideal Corner Radius: Balances cutting forces to ensure a smooth finish.

4. Chip Control

- Chip Breakers: Effectively manage chip flow, preventing clogging and maintaining cutting efficiency.

Applications of Type A Carbide Brazed Tips

Type A carbide brazed tips are versatile and can be used in various industries and applications:

1. Metalworking

- Turning Operations: Precision machining of cylindrical parts.

- Milling Operations: Efficient material removal in milling processes.

- Drilling Operations: High-performance drilling in various materials.

2. Woodworking

- Cutting and Shaping: Precision cutting and shaping of wooden components.

- Routing: High-speed routing for intricate designs and patterns.

3. Automotive Industry

- Engine Component Machining: Precise machining of engine parts for optimal performance.

- Transmission Part Manufacturing: High-precision machining of transmission components.

4. Aerospace Industry

- Aircraft Component Machining: Machining of critical aircraft components with high precision.

- Landing Gear Machining: Durable and precise machining of landing gear parts.

Comparative Analysis of Type A Carbide Brazed Tips

The table below highlights the impact of different geometric parameters on cutting performance for Type A carbide brazed tips:

| Geometric Parameter | Positive Impact | Negative Impact |

|---|---|---|

| Rake Angle | Reduced cutting forces, improved efficiency | Lower tool strength |

| Relief Angle | Reduced friction, enhanced surface finish | Potential for increased tool wear if excessive |

| Cutting Edge Angle | Increased tool strength, extended tool life | Higher cutting forces |

| Corner Radius | Improved surface finish, reduced wear | Higher cutting forces, potential for chatter |

Advantages and Disadvantages of Type A Carbide Brazed Tips

The table below outlines the pros and cons of Type A carbide brazed tips:

| Feature | Advantages | Disadvantages |

|---|---|---|

| Positive Rake Angle | Reduced cutting forces, improved chip flow | Lower tool strength, potential for chipping |

| Optimal Relief Angle | Reduced friction, enhanced surface finish | Potential for increased tool wear if excessive |

| Sharp Cutting Edge | Precise cuts, excellent surface finish | Requires careful handling to prevent damage |

| Ideal Corner Radius | Improved surface finish, reduced tool wear | Higher cutting forces, potential for chatter |

Factors to Consider When Choosing Type A Carbide Brazed Tips

Selecting the right Type A carbide brazed tips involves considering several factors:

- Material Being Machined: Different materials require specific geometries and designs for optimal cutting performance.

- Cutting Conditions: Factors such as cutting speed, feed rate, and depth of cut influence the choice of tip geometry.

- Machining Application: The type of machining operation (e.g., turning, milling, drilling) dictates the appropriate tip design.

- Tool Holder and Machine Compatibility: Ensuring the carbide brazed tip is compatible with the tool holder and machine specifications.

Related Topics: Advanced Coatings for Type A Carbide Brazed Tips

In addition to geometry and design, advanced coatings play a significant role in enhancing the performance of Type A carbide brazed tips. Coatings such as Titanium Nitride (TiN), Titanium Carbonitride (TiCN), and Aluminum Titanium Nitride (AlTiN) provide additional benefits:

- Reduced Friction: Coatings reduce friction between the tool and workpiece, enhancing cutting efficiency.

- Increased Wear Resistance: Coatings protect the tool from wear, extending its life.

- Improved Heat Resistance: Coatings help dissipate heat, preventing thermal damage to the tool.

Why Choose Type A Carbide Brazed Tips for High-Performance Machining

Type A carbide brazed tips are an excellent choice for high-performance machining due to their superior hardness, wear resistance, and ability to maintain cutting efficiency under extreme conditions. The combination of optimized geometry and advanced design ensures these tools deliver precise, efficient cuts, making them indispensable in various industries.

FAQ

1. How does the positive rake angle affect cutting performance?

A: The positive rake angle reduces cutting forces and improves chip flow, making the cutting process more efficient. However, it may compromise tool strength if not properly balanced.

2. What is the importance of the relief angle in Type A carbide brazed tips?

A: The relief angle prevents friction and heat buildup between the tool and workpiece, enhancing cutting efficiency and reducing tool wear.

3. How do chip breakers enhance cutting performance?

A: Chip breakers control chip flow and prevent clogging, maintaining cutting efficiency and reducing the risk of tool damage.

4. What factors should be considered when selecting a corner radius?

A: The corner radius affects surface finish and tool wear. A larger radius improves finish and reduces wear but requires higher cutting forces.

5. How do coatings improve the performance of Type A carbide brazed tips?

A: Coatings reduce friction, increase wear resistance, and improve heat dissipation, enhancing the overall performance and longevity of the tools.

Understanding the geometry and design of Type A carbide brazed tips is essential for optimizing their cutting performance. By selecting the right tips and considering factors such as material, cutting conditions, and application, you can achieve superior machining results, improve efficiency, and extend the life of your cutting tools.

Conclusion

Type A carbide brazed tips are a testament to the power of precise engineering and innovative design. Their unique geometry and design features make them a versatile and reliable choice for various machining applications. By understanding how these factors influence cutting performance, you can make informed decisions that elevate your machining operations to new heights.