Overview of wear resistant plate carbide

Wear resistant plate carbide refers to composite plates containing very hard tungsten or chromium carbide particles dispersed in a metal matrix like iron, nickel or cobalt. These plates exhibit exceptional abrasion and erosion resistance making them suitable for high wear applications.

Key properties and composition details of wear resistant carbide plates:

wear resistant plate carbide Properties

| Property | Description |

|---|---|

| Matrix Material | Iron, Nickel, Cobalt |

| Reinforcement | Tungsten carbide, Chromium carbide |

| Hardness | Up to 65 HRC |

| Abrasion Resistance | Excellent |

| Impact Strength | Moderate |

| Temperature Resistance | Up to 850°C |

Applications of wear resistant plate carbide

Wear resistant carbide plates find usage in:

Wear Resistant Plate Carbide Applications

| Industry | Typical Applications |

|---|---|

| Mining | Chutes, piping, screening, crushing, grinding, conveying |

| Cement | Fan blades, separators, chutes, cyclones, diverter valves |

| Agriculture | Plough discs, cultivator tips |

| Food Processing | Cutting blades, meat grinders, canning equipment |

| Pulp & Paper | Refiner bars, fan pump parts |

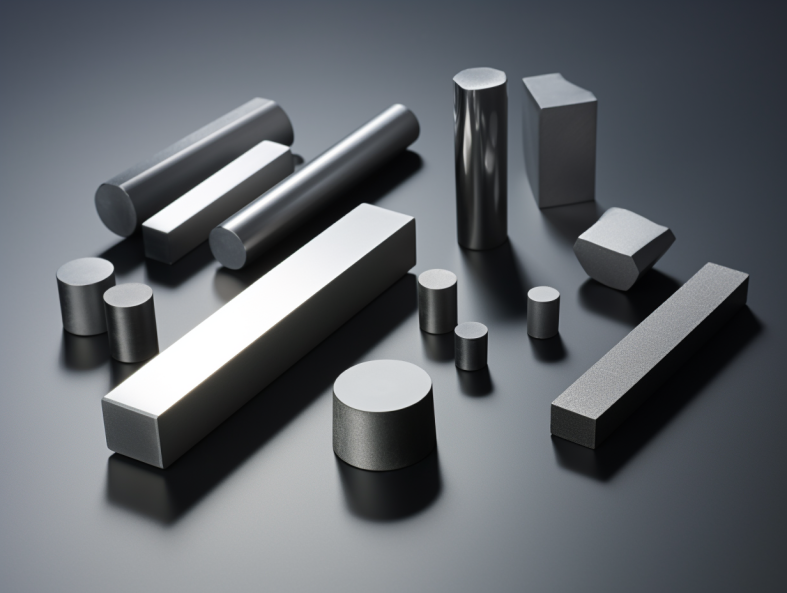

wear resistant plate carbide Specifications and Grades

Various grades of wear resistant plate carbides are available:

Wear Resistant Plate Carbide Grades

| Grade | Description |

|---|---|

| WC-Ni | Tungsten carbide in nickel matrix for corrosion resistance |

| WC-Co | Cobalt matrix for high temperature resistance |

| CrC-Ni | Chromium carbide nickel matrix optimized for sliding abrasion |

| CrC-Fe | Cost effective iron matrix chromium carbide grade |

These plates adhere to specifications like ASTM B777, ASTM B779 for cobalt and nickel tungsten carbide plates.

wear resistant plate carbide Suppliers and Pricing

Some major global suppliers and price ranges:

Wear Resistant Plate Carbide Suppliers

| Supplier | Grades Offered | Price Range* |

|---|---|---|

| Kennametal | WC-Ni, WC-Co | $40-$100 per Kg |

| Sandvik | WC-Ni, CrC-Ni, CrC-Fe | $30-$120 per Kg |

| Hardface International | WC-Co, CrC-Fe | $25-$90 per Kg |

* Prices vary based on order volumes, dimensions and customization requirements.

How Carbide Plate Compares

Comparison of wear resistant carbide plate with alternatives:

Comparison of Wear Resistant Materials

| Parameter | Carbide Plate | AR Plate | Ceramic Plate |

|---|---|---|---|

| Abrasion Resistance | Excellent | Very Good | Good |

| Toughness | Good | Excellent | Poor |

| Temperature Resistance | Up to 850°C | Up to 600°C | Up to 1000°C |

| Cost | Moderate | Low | High |

Carbide plate offers the best balance of wear resistance with moderate cost and temperature resistance.

Key Considerations for Carbide Plate

Some special considerations for working with wear resistant carbide plate:

Wear Resistant Plate Carbide Considerations

| Consideration | Details |

|---|---|

| Lead Time | Typically 4-8 weeks with customization |

| Part Size Capabilities | Up to 2000 mm x 1000 mm available |

| Machining Difficulty | Challenging, requires diamond tooling |

| Weight | Two to four times heavier than steel |

| Maintenance | Periodic inspection for cracks or damage needed |

FAQs

Q: What is wear resistant carbide plate?

A: Wear resistant carbide plate consists of an extremely hard tungsten or chromium carbide reinforcement dispersed in a metal matrix like nickel, iron or cobalt. This provides exceptional resistance to sliding, abrasive and erosive wear.

Q: What industries use wear resistant carbide plates?

A: Major industries using these plates include mining, cement, agriculture, food processing, pulp & paper anywhere high wear conditions are encountered in chutes, piping, fan blades, machinery parts etc.

Q: How long do carbide wear plates last?

A: Depending on the application and operating conditions, wear resistant carbide plates provide 5-10 times longer service life compared to regular steel. Life expectancy can reach thousands of hours before replacement is needed.

Q: Can you cut and machine carbide wear plate?

A: Yes carbide wear plates can be cut and machined using diamond abrasive slicing and grinding. Carbide is extremely hard so rigidity and specialized tooling is essential during machining.

Q: Should wear resistant plate carbide be sealed or coated?

A: In very corrosive environments, sealing or applying specialized coatings can enhance the functional life of carbide wear components and prevent chemical attack on the metal matrix binding the carbide particles.