Carbide blanks with holes are an important type of tool blank used in a variety of machining and manufacturing applications. This comprehensive guide provides detailed information on carbide blanks with holes to help you understand their characteristics, applications, specifications, suppliers, installation, operation and maintenance.

Overview of Carbide Blanks with Holes

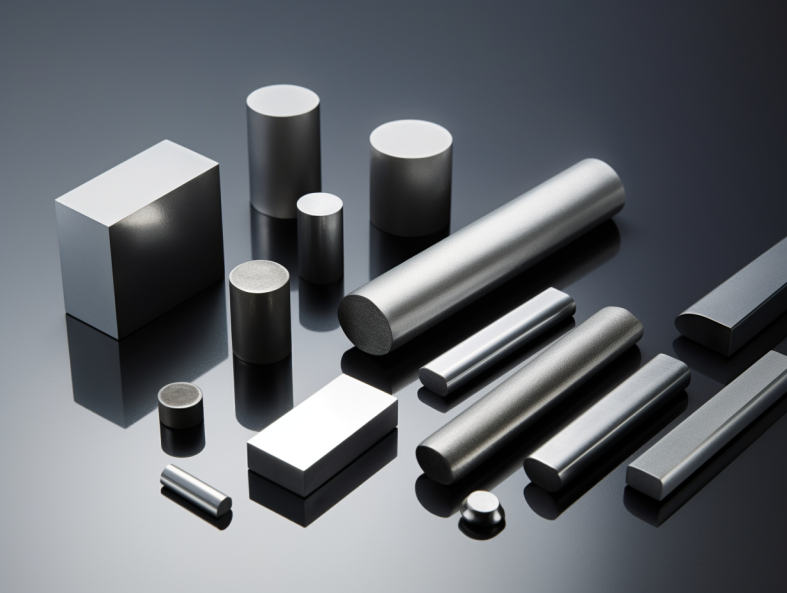

Carbide blanks with holes refer to tool blanks made of tungsten carbide that have pre-drilled holes in them. The holes enable mounting and chucking of the carbide for further machining and finishing into a cutting tool.

Carbide is an extremely hard and durable material composed of tungsten carbide particles bonded together by a metallic binder like cobalt. It has high strength, hardness and wear resistance which makes it ideal for cutting tools. The pre-drilled holes in the blanks facilitate secure holding and accurate machining of the carbide into the desired tool geometry.

The main features of carbide blanks with holes are:

- Made of tungsten carbide for hardness and durability

- Have accurately located pre-drilled holes for mounting

- Available in round, square or rectangular cross-sections

- Holes can be simple through-holes or complex patterns

- Allows further machining into finished cutting tools

- Used for various tool types like drills, end mills, reamers etc.

- Enables secure clamping and precision machining of carbide

Carbide blanks with holes provide a starting point to manufacture fully functional cutting tools tailored to the required specifications. The blanks are made to standard sizes and hole configurations to fit tool holding systems and machining equipment. Custom hole patterns are also available.

Types of Carbide Blanks with Holes

Carbide blanks are available in a range of standard and custom sizes and shapes with different hole patterns to suit various tool types and machining requirements.

Based on Cross-Section

- Round blanks – Most common, ideal for drills, end mills etc.

- Square blanks – For form tools, grooving tools, lathe tools etc.

- Rectangular blanks – For parting tools, cutoff tools, specialty applications

Based on Hole Pattern

- Single centered hole – For rotational symmetry tools like drills

- Off-center holes – For end mills, routers, asymmetric tools

- Multiple holes – For better clamping, anti-rotation

- Special hole patterns – For custom tool designs

Based on Mounting System

- Cylindrical shank – For chucking in collets, holders

- Tapered shank – For mounting in tool tapers like CAT, BT, IT, DT etc.

- Threaded shank – For screw-based holding systems

- Customized shanks – For specialty machine interfaces

Based on Application

- Roughing blanks – For rough machining applications

- Finishing blanks – Closer geometrical tolerances for finishing

- Drilling blanks – For machining drills and boring tools

- Milling blanks – For end mills, routers, engravers etc.

- Form tool blanks – For form turning, cutting complex profiles

Based on Quality

- Production grade – General purpose for high volume machining

- Precision grade – Tighter tolerances for precision boring, milling etc.

- High performance – Finer grain carbides for high-speed applications

Applications and Uses of Carbide Blanks with Holes

Carbide blanks with holes are used to manufacture a wide variety of cutting tools for different machining applications.

Milling Tools

- End mills

- Ball end mills

- Face mills

- Roughers, Finishers

- Chamfer mills

- Slot drills

Drilling and Boring Tools

- Twist drills

- Gun drills

- Boring heads

- Reamers

- Counterbores, Countersinks

Turning and Grooving Tools

- External turning inserts

- Internal grooving inserts

- Parting off blades

- Form turning tools

- Threading tools

Specialty Tools

- Engraving cutters

- Gear hobbs

- Broaches

- Burrs

- Slitting saws

- Router bits

Carbide blanks with holes enable secure holding and precise grinding/machining of these tools as per the required geometries and dimensions. The choice of blank depends on factors like tool size, carbide grade, tolerance requirements and complexity of tool geometry.

Specifications of Carbide Blanks with Holes

Carbide blanks are available in standard and custom sizes with dimensions and geometries as per toolholding standards and machine interface requirements. Here are some key specifications:

Blank Dimensions

| Parameter | Range |

|---|---|

| Diameter | 0.5 mm – 75 mm |

| Length | 10 mm – 150 mm |

| Width | 2 mm – 50 mm (non-round blanks) |

| Thickness | 1 mm – 25 mm (non-round blanks) |

Hole Dimensions

| Parameter | Range |

|---|---|

| Hole diameter | 2 mm – 22 mm |

| Number of holes | 1 – 8 |

| Hole depth | Through holes or Blind holes |

| Hole position | Centered, Off-center, Patters |

Tolerances

| Parameter | Tolerance |

|---|---|

| Diameter | ±0.02 mm – ±0.15 mm |

| Length | ±0.02 mm – ±0.15 mm |

| Hole position | ±0.01 mm – ±0.1 mm |

| Hole diameter | H7 to H11 |

| Hole depth | ±0.05 mm – ± 0.2 mm |

| Surface finish | Up to 0.4 μm Ra |

| Squareness | <0.002 mm/mm |

Carbide Grades

- Fine, micro and ultra-fine grain carbides

- Grades like C1 to C5 based on cobalt content

- Coating options like TiAlN, TiCN etc. on request

Design and Standards

Carbide blanks are designed as per international standards for tool holding interfaces and to fit standard machine collet and taper sizes. Common standards include:

Shank Types:

- Cylindrical (Weldon, Flat)

- VDI Radial Locking

- BT, CAT, SK, HSK Tool Tapers

- Capto, Coromant, KM Quick Change

- Heat Shrink Locking

- Hydraulic Expansion Locking

Blank Dimensions:

- ANSI B94.19 – Round shank tool blanks

- DIN 6535 HA – Tool shanks, tapers

- ISO 13399 – Tool holders for milling

- JIS B6339 – End mill shanks

- ASME B94.11M – Indexable inserts

Hole Patterns:

- DIN 6535 HB – Circular tool shanks

- JIS B6339 – Tool shanks for end mills

- SECO Toolkit System

- Specific holder manufacturer standards

Using standard blanks streamlines tool design, clamping, manufacturing and changeovers. Custom blanks can also be produced.

Suppliers and Pricing

Carbide blanks with holes are stocked by major cutting tool manufacturers, carbide suppliers and tooling resellers. Here are some common suppliers and price ranges:

Manufacturers:

- Kennametal

- Sandvik Coromant

- Mitsubishi Materials

- OSG

- Nachi

- Sumitomo

- Kyocera

- Guhring

Carbide Suppliers:

- Carbide USA

- Advent Tool and Manufacturing

- Carried Tools

- Harvey Tool

- Midwest Cutting Tools

Average Price Range:

| Blanks | Price per piece |

|---|---|

| Micrograin 3mm drill blanks | $8 – $12 |

| 6mm end mill blanks | $15 – $22 |

| 20mm face mill blanks | $45 – $68 |

| 32mm boring head blanks | $85 – $150 |

Bulk discounts available. Advanced grades and special sizes cost more. Precision-tolerance Prototyping blanks are pricier. Overall range is $5 to $300 per blank depending on dimensions and grade.

Installation and Operation

Carbide blanks need to be properly installed in appropriate tool holding systems and machine interfaces for further machining and finishing into cutting tools.

Mounting Methods:

- Collet Chucks for round shank blanks

- Hydraulic/Shrink fit tool holders

- Machine tapers like CAT, BT, HSK, SK

- Set-screw tool blocks for non-rotating tools

Machining Guidelines

- Use rigid setups to prevent vibration

- Follow recommended cutting parameters

- Use coolant for better finish and prevention of edge buildup

- Polish edges lightly to relieve stress risers

- Clean blanks thoroughly after machining

Finishing Steps

- Grinding and honing edge profiles

- Coating by PVD, CVD techniques

- Laser etching graphics, markings

- Balance tool to G2.5 at operating speeds

- Measure runout, test tool before use

Proper workholding, machining techniques and finishing ensures correct geometry, performance and safety.

Maintenance of Carbide Blanks

Maintaining carbide blanks properly is important for functionality and longevity of the tools machined from them.

- Store blanks in a clean, dry place in packaging

- Avoid temperature extremes during storage

- Ensure no stresses are present before machining

- Careful handling to prevent edges being damaged

- Clean blankets with solvents before machining

- Re-sharpen or replace tools once worn out

- Re-coat tools periodically for protection

With care and re-sharpening, carbide tools can last for years. Damaged blanks should not be machined into tools. Regular inspection ensures long working life.

How to Select Carbide Blanks

Selection of suitable carbide blanks is important for efficient machining and good performance of the final tool.

Blank Diameter

Match shank size to toolholder inner diameter for stability. Avoid excessive overhang.

Carbide Grade

Harder grades for ferrous materials. Tougher grades for interrupted cuts. Coatings for high speeds.

Hole Pattern

Must suit toolholder system. Anti-rotation holes preferred for non-rotating tools.

Tolerances

General tolerance blanks for roughing. Tighter tolerance ones for finishing.

Number of Teeth

Sufficient circumference length needed on milling cutter blanks.

Coolant Holes

Through-hole blanks easier to machine for coolant delivery.

Section Shape

Round blanks for drills. Square ones for grooving. Rectangular for parting tools.

The tool designer selects optimum blank configurations based on application requirements.

Advantages of Carbide Blanks with Holes

Carbide blanks with holes offer various benefits for manufacturing cutting tools:

- Enable secure clamping and support of carbide preforms

- Facilitate concentric and precise machining of carbide into tools

- Provide starting raw material geometry for various tool types

- Allow carbide edge micro-geometries to be ground

- Suitable for high volume production of optimized tools

- Holes assist coolant delivery to cutting edges

- Standard blank sizes compatible with toolholding systems

- Holes permit anti-rotation locking for non-rotating tools

- Can be made with very hard and wear-resistant carbide grades

- Consistent quality of blanks ensures tool accuracy

Limitations of Carbide Blanks with Holes

Some limitations associated with using carbide blanks are:

- Additional pre-processing needed versus finished inserts

- Requires grinding equipment and setups for toolmaking

- More costly for prototyping and custom tools in small volumes

- Hole position and quality must meet tight tolerances

- Carbide is brittle and blanks prone to chipping if mishandled

- Limited geometry complexity compared to PCD-tipped tools

- Re-sharpening or replacement needed after use

- Not suitable for applications requiring very high dynamic stiffness

Comparison Between Carbide Blanks and Inserts

Carbide blanks differ from pre-made indexable inserts in terms of geometry, application and manufacturing advantages:

| Parameter | Carbide Blanks | Indexable Inserts |

|---|---|---|

| Geometry | Requires grinding after clamping in tool | Pre-shaped geometry |

| Tools Produced | Drills, mills, custom shapes | Mainly inserts for turning |

| Setups Needed | Tool grinding or machining | Just tool assembly |

| Production Volume | Medium to high | Very high |

| Lead Time | Longer due to machining | Faster due to ready inserts |

| Cost | Lower for large production | Lower for very high volumes |

| Flexibility | More flexible due to ability to customize tool shape | Limited insert geometries |

| Quality Control | Controlled via in-house grinding | Pre-set by insert molding process |

Carbide blanks allow flexible production of various tool types but require more processing. Indexable inserts enable fast mass production but have limited geometry options.

Frequently Asked Questions

What are the most common hole configurations in carbide blanks?

For round tool shanks, the most common are single centered holes, dual off-center holes, and cross-holes or quadruple hole patterns. For tapered shanks, single axial holes or dual radial holes are prevalent.

What precision can be achieved when machining tools from carbide blanks?

With CNC tool grinding and EDM technology, carbide blanks can be machined into cutting tools with tolerances down to ±2 microns and surface finishes under Ra 0.2 microns.

How should carbide blanks be handled to avoid damage?

Carbide blanks have brittle edges and corners vulnerable to chipping. Care should be taken to avoid striking the edges and stressing the blanks during handling, clamping and machining. Padded handling fixtures help.

Can coolant delivery holes be incorporated when machining tools from blanks?

Yes, through-hole carbide blanks facilitate drilling intersecting holes for delivering coolant to the cutting edges and chip flutes of tools like endmills. But blind hole blanks limit internal coolant options.

What are shrink-fit tool holders used for with carbide blanks?

Shrink-fitting uses temperature differential to create an interference fit between the carbide blank and steel toolholder for secure clamping without movement or runout. It is a preferred method for high performance machining.

What are some best practices for sharpening carbide cutting tools?

Use dedicated tool grinding equipment, follow recommended grinding feeds/speeds for the carbide grade, use coolant, sharpen in multiple stages, apply light stoning to deburr, avoid overheating or shocking carbide. Re-coat after sharpening.

Conclusion

Carbide blanks containing pre-drilled holes are a versatile material for efficiently manufacturing a wide range of cutting tools to meet production requirements. By using blanks with suitable dimensions, carbide grade and hole patterns based on the tool design needs, quality tools can be machined and finished precisely for various applications. With standards continuing to evolve and advanced carbide grades being developed, carbide blank technologies will keep enabling optimized cutting tool production.