The automotive industry thrives on innovation, constantly seeking materials that enhance performance, efficiency, and longevity. Enter tungsten carbide blanks – incredibly hard, wear-resistant components that form the foundation for a wide range of critical automotive parts. This comprehensive guide delves into the multifaceted world of tungsten carbide blanks, exploring their properties, applications within the automotive sector, and the factors driving their increasing adoption.

What are Tungsten Carbide Blanks?

The Foundation of Durability: Unmatched Hardness and Wear Resistance

Tungsten carbide blanks are pre-sintered, near-net-shape components composed of tungsten carbide particles bonded together with a metallic binder, typically cobalt. This unique composition imparts exceptional hardness and wear resistance, surpassing even the toughest steels.

Properties of Tungsten Carbide Blanks: Tailored for Demanding Applications

Table 1: Key Properties of Tungsten Carbide Blanks for Automotive Applications

| Property | Description | Benefits in Automotive Applications |

|---|---|---|

| High Hardness | Measures resistance to indentation and scratching. Tungsten carbide ranks among the hardest materials known. | Enables components to withstand extreme wear and tear, extending lifespan and reducing maintenance. |

| Excellent Wear Resistance | Resists material loss due to friction, abrasion, or erosion. | Crucial for parts subjected to constant friction, like engine components and cutting tools. |

| High Compressive Strength | Withstands high compressive forces without deformation or fracture. | Essential for components subjected to significant pressure, such as bearings and valve seats. |

| Good Corrosion Resistance | Resists degradation from exposure to chemicals, moisture, and corrosive environments. | Ensures longevity in demanding automotive environments, especially under the hood. |

| High Hot Hardness | Maintains hardness and strength at elevated temperatures. | Critical for components operating at high temperatures, like engine parts and exhaust systems. |

Applications in the Automotive Industry: Where Durability Meets Performance

Tungsten carbide blanks play a crucial role in a wide array of automotive applications, including:

- Engine Components: Valve seats, valve guides, fuel injectors, and piston rings benefit from the extreme wear resistance and high-temperature performance of tungsten carbide.

- Transmission Systems: Gears, bearings, and synchronizer rings utilize tungsten carbide to withstand high loads, friction, and wear, ensuring smooth and efficient power transmission.

- Braking Systems: Brake pads, brake discs, and ABS components leverage the hardness and wear resistance of tungsten carbide to enhance braking performance and extend service life.

- Steering and Suspension: Steering components, suspension bushings, and wheel bearings benefit from the durability and wear resistance of tungsten carbide, ensuring precise handling and prolonged lifespan.

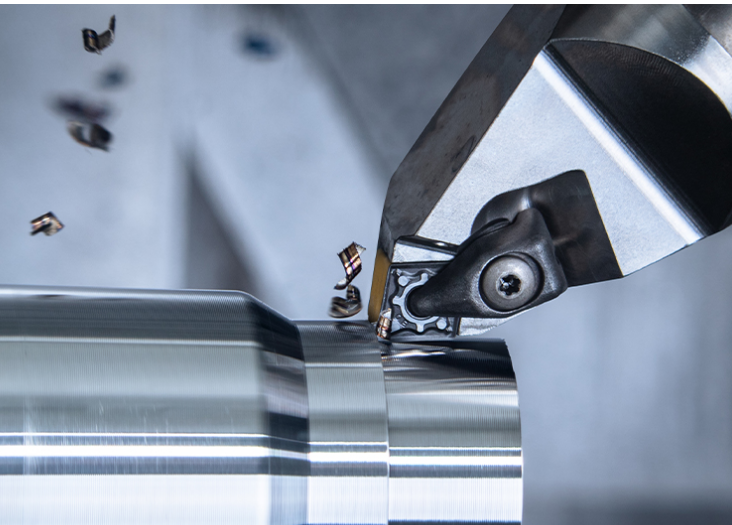

- Manufacturing Equipment: Cutting tools, dies, and wear parts used in automotive manufacturing rely on tungsten carbide’s exceptional hardness to machine and shape various components.

Market Trends and Drivers: Fueling the Demand for Durability

Several factors are driving the increasing adoption of tungsten carbide blanks in the automotive industry:

- Focus on Fuel Efficiency: Lighter-weight vehicles with more efficient engines demand durable components that can withstand increased stress and operating temperatures.

- Stringent Emissions Regulations: Advanced engine technologies and emissions control systems require robust materials like tungsten carbide to handle higher combustion pressures and temperatures.

- Demand for Vehicle Longevity: Consumers expect vehicles to last longer, driving the need for components with exceptional wear resistance and extended service life.

- Growth of Electric Vehicles (EVs): EVs present unique challenges and opportunities for materials science. Tungsten carbide’s properties make it suitable for various EV components, including electric motors, battery systems, and power electronics.

Comparing Suppliers: Navigating the Tungsten Carbide Blank Market

Table 2: Leading Suppliers of Tungsten Carbide Blanks for the Automotive Industry

| Supplier | Location | Price Range (USD/kg) | Specialties |

|---|---|---|---|

| Kennametal | USA | $80 – $250+ | Wide range of carbide grades, custom formulations, technical expertise |

| Sandvik Coromant | Sweden | $90 – $280+ | High-performance carbide grades, precision machining, application support |

| Element Six | UK, Global | $100 – $300+ | Advanced carbide materials, specialized grades for demanding applications |

| Ceratizit | Luxembourg | $75 – $230+ | Cost-effective solutions, wide range of standard grades, global presence |

| TRUER | China | $70 – $220+ | High-quality carbide blanks, competitive pricing, fast lead times for custom orders |

Note: Prices are approximate and vary based on grade, size, quantity, and market conditions.

Advantages and Limitations: A Balanced Perspective on Performance

Table 3: Pros and Cons of Tungsten Carbide Blanks in Automotive Applications

| Advantages | Limitations |

|---|---|

| Exceptional Durability and Wear Resistance: Significantly extends component lifespan, reduces maintenance requirements, and enhances reliability. | High Initial Cost: Tungsten carbide blanks are typically more expensive than steel counterparts. |

| Improved Performance and Efficiency: Enhances engine efficiency, optimizes power transmission, and improves braking performance. | Brittle Nature: Susceptible to chipping or fracturing under extreme impact or shock loads. |

| Reduced Weight and Size: Enables the use of smaller, lighter components without compromising strength or durability. | Machining Challenges: Requires specialized machining techniques and equipment due to extreme hardness. |

Beyond the Blank: Factors Influencing Performance and Longevity

Realizing the full potential of tungsten carbide blanks in automotive applications extends beyond material selection. Key considerations include:

- Grade Selection: Choosing the appropriate carbide grade based on specific application requirements, such as wear resistance, impact resistance, and corrosion resistance.

- Coating Technologies: Applying specialized coatings can further enhance wear resistance, reduce friction, and improve performance in demanding environments.

- Design Optimization: Designing components to leverage the unique properties of tungsten carbide, considering factors like stress distribution, wear patterns, and thermal expansion.

Why Choose TRUER for Your Tungsten Carbide Blank Needs?

TRUER stands out as a premier supplier of high-quality tungsten carbide blanks, offering:

- Unwavering Commitment to Quality: TRUER utilizes premium raw materials and stringent quality control measures throughout the manufacturing process to ensure consistent performance and reliability.

- Technical Expertise: TRUER’s team of experienced engineers possesses in-depth knowledge of carbide grades, applications, and processing techniques, providing valuable support and guidance.

- Competitive Pricing: TRUER’s efficient operations and customer-centric approach enable them to offer competitive pricing without compromising quality.

- Fast Lead Times: TRUER understands the importance of timely delivery and strives to provide prompt lead times, even for custom orders.

FAQs: Addressing Your Tungsten Carbide Blank Queries

1. What is the best tungsten carbide grade for my specific automotive application?

The optimal grade depends on factors like operating conditions, wear mechanisms, and required properties. TRUER’s technical experts can recommend the most suitable grade based on your specific needs.

2. Can tungsten carbide blanks be coated to enhance their properties?

Yes, various coatings, such as CVD (Chemical Vapor Deposition) and PVD (Physical Vapor Deposition), can further enhance wear resistance, reduce friction, and improve performance in demanding environments.

3. What are the key considerations for machining tungsten carbide blanks?

Machining tungsten carbide requires specialized equipment, tooling, and expertise due to its extreme hardness. TRUER can provide guidance on machining parameters and best practices.

4. How do I ensure the quality and consistency of tungsten carbide blanks?

TRUER implements rigorous quality control measures throughout the manufacturing process, including material analysis, dimensional inspection, and performance testing.

5. Does TRUER offer custom tungsten carbide blank solutions?

Yes, TRUER specializes in providing customized solutions tailored to specific application requirements. Their team can design and manufacture blanks to meet unique challenges.