Introduction

Definition of Cement Carbide Rods

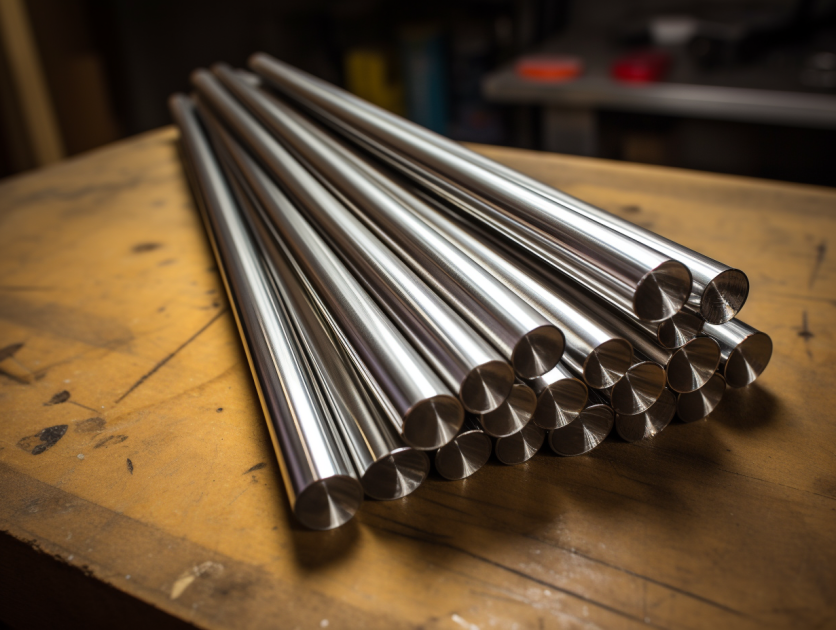

Cement carbide rods, also known as tungsten carbide rods, are cylindrical tools made from a combination of cemented carbide and other materials. These rods are widely used in various industries, including manufacturing, construction, and mining, due to their exceptional hardness and durability. The main purpose of cement carbide rods is to provide cutting, drilling, and shaping capabilities in applications where high precision and resistance to wear are required. With their excellent heat resistance and ability to withstand extreme conditions, cement carbide rods have become an essential tool for professionals in the field. Whether it’s for machining metal, drilling through concrete, or carving intricate designs, cement carbide rods offer unmatched performance and reliability.

History of Cement Carbide Rods

Cement carbide rods have a rich history that dates back to the late 19th century. The development of cement carbide rods can be attributed to the pioneering work of Thomas Willson, who discovered the process of producing calcium carbide. This breakthrough led to the creation of cement carbide rods, which quickly became popular due to their exceptional hardness and durability. Over the years, cement carbide rods have been widely used in various industries, including mining, construction, and metal fabrication. Today, these rods continue to be a crucial component in many applications, providing strength and reliability in demanding environments.

Applications of Cement Carbide Rods

Cement carbide rods are widely used in various industries due to their exceptional properties. One of the major applications of cement carbide rods is in the manufacturing of cutting tools. These rods are known for their high hardness and excellent wear resistance, making them ideal for cutting and machining operations. Additionally, cement carbide rods are also used in the production of mining and drilling tools. Their durability and toughness make them suitable for withstanding the harsh conditions encountered in mining and drilling activities. Moreover, cement carbide rods find applications in the construction industry, where they are used for drilling holes in concrete and other hard materials. The versatility and reliability of cement carbide rods make them an indispensable component in several industrial applications.

Composition

Materials Used in Cement Carbide Rods

Cement carbide rods are manufactured using a combination of high-quality materials. These materials include cement, carbide, and other additives that enhance the performance and durability of the rods. Cement, known for its binding properties, forms the base of the rods, providing strength and stability. Carbide, on the other hand, adds hardness and wear resistance to the rods, making them suitable for various applications. The precise combination of these materials ensures that cement carbide rods exhibit excellent cutting performance and can withstand extreme conditions. With their exceptional quality and reliability, cement carbide rods have become an essential component in industries such as construction, mining, and metalworking.

Manufacturing Process of Cement Carbide Rods

The manufacturing process of cement carbide rods involves several steps. Firstly, raw materials such as calcium carbide and graphite are carefully selected and mixed in precise proportions. This mixture is then heated in an electric furnace at high temperatures, causing a chemical reaction that transforms the raw materials into a molten state. The molten mixture is then poured into molds of desired shapes and sizes. After cooling and solidification, the rods are removed from the molds and undergo further processing to achieve the desired properties. This may include grinding, polishing, and heat treatment. Finally, the finished cement carbide rods are inspected for quality and packaged for distribution to various industries where they are used in applications such as cutting tools, mining tools, and wear-resistant parts.

Properties of Cement Carbide Rods

Cement carbide rods possess remarkable properties that make them highly desirable for various applications. Firstly, these rods exhibit exceptional hardness, making them resistant to wear and tear. This property ensures their longevity and durability in demanding environments. Additionally, cement carbide rods have excellent thermal conductivity, allowing for efficient heat dissipation. This feature is particularly beneficial in high-temperature applications where heat management is crucial. Moreover, these rods have superior strength and toughness, enabling them to withstand heavy loads and impacts. Lastly, cement carbide rods have excellent corrosion resistance, making them suitable for use in corrosive environments. Overall, the exceptional properties of cement carbide rods make them a reliable choice for a wide range of industrial applications.

Advantages

High Hardness and Wear Resistance

Cement carbide rods are renowned for their exceptional high hardness and wear resistance. These rods are specifically designed to withstand the most challenging industrial applications, where durability and longevity are paramount. With a hardness rating that surpasses that of traditional steel rods, cement carbide rods offer superior performance and reliability. The unique composition of cement carbide, combined with advanced manufacturing techniques, results in a product that can withstand extreme wear and tear, making it an ideal choice for industries such as mining, construction, and metalworking. Whether it’s drilling, cutting, or grinding, cement carbide rods deliver unmatched performance, ensuring increased productivity and reduced downtime. In addition to their exceptional hardness and wear resistance, these rods also exhibit excellent thermal stability and corrosion resistance, further enhancing their suitability for demanding environments. When it comes to high hardness and wear resistance, cement carbide rods are the ultimate solution for industries that require robust and reliable tools.

Excellent Heat Resistance

Cement carbide rods exhibit excellent heat resistance, making them a valuable material in various industries. With the ability to withstand high temperatures without deformation or degradation, these rods are ideal for applications where heat resistance is critical. Whether it is in the manufacturing of cutting tools, drilling equipment, or furnace components, cement carbide rods provide exceptional performance and reliability. Additionally, their heat resistance allows for prolonged usage in extreme conditions, ensuring longevity and durability. Overall, the outstanding heat resistance of cement carbide rods makes them an indispensable choice for industries that require reliable and high-performing materials.

Wide Range of Applications

Cement carbide rods have a wide range of applications in various industries. These rods are known for their exceptional hardness and durability, making them suitable for cutting, drilling, and shaping hard materials. They are commonly used in the manufacturing and construction industries for tasks such as cutting metal, drilling holes in concrete, and shaping stone. Additionally, cement carbide rods are also utilized in the mining industry for rock drilling and excavation. With their versatility and strength, these rods play a crucial role in enhancing productivity and efficiency in numerous applications across different sectors.

Disadvantages

Brittleness

Brittleness is a key characteristic of cement carbide rods. Due to their composition and structure, these rods are highly susceptible to cracking or breaking when subjected to stress or impact. This property makes them ideal for applications where a high level of precision and rigidity is required. However, it also means that caution must be exercised during handling and use to prevent any damage. Manufacturers of cement carbide rods often employ various techniques to enhance their strength and reduce brittleness, such as incorporating additives or optimizing the manufacturing process. Overall, understanding and managing the brittleness of cement carbide rods is crucial for ensuring their reliable performance in various industries.

High Cost

Cement carbide rods are known for their exceptional durability and strength, making them a popular choice in various industries. However, one drawback of these rods is their high cost. The manufacturing process and the raw materials involved contribute to the overall expense. Despite the higher price tag, many companies still opt for cement carbide rods due to their long lifespan and superior performance. The investment in these rods pays off in the long run, as they require less frequent replacement and deliver consistent results. Although the high cost may be a deterrent for some, the benefits and advantages offered by cement carbide rods make them a worthwhile investment for those seeking reliability and longevity.

Environmental Impact

Cement carbide rods have a significant environmental impact due to their production and disposal. The manufacturing process of these rods involves the extraction of raw materials and the release of greenhouse gases. Additionally, the disposal of used carbide rods can lead to soil and water contamination. It is important to consider alternative materials or recycling options to minimize the environmental footprint of cement carbide rods.

Uses

Cutting Tools

Cement carbide rods are essential components in the manufacturing of cutting tools. These rods are known for their exceptional hardness and durability, making them ideal for applications that require precision cutting. The high-quality cement carbide material ensures that the cutting tools maintain their sharpness for extended periods, resulting in efficient and accurate cutting operations. Additionally, cement carbide rods offer excellent resistance to wear and corrosion, further enhancing their longevity. With their superior performance and reliability, cutting tools made from cement carbide rods are widely used in industries such as metalworking, woodworking, and construction.

Mining and Drilling

Mining and drilling industries heavily rely on cement carbide rods for various applications. These rods are essential in the extraction of minerals and ores from the earth’s crust. They provide the necessary strength and durability to withstand the harsh conditions encountered during mining and drilling operations. Cement carbide rods are commonly used in rock drilling, tunneling, and well drilling activities. Their high resistance to wear and excellent cutting performance make them ideal for these demanding tasks. Moreover, these rods are also used in the manufacturing of drilling tools and equipment, further highlighting their importance in the mining and drilling sectors. Overall, cement carbide rods play a vital role in ensuring the efficiency and productivity of mining and drilling operations.

Industrial Machinery

Cement carbide rods are an essential component in the field of industrial machinery. These rods are known for their exceptional hardness and durability, making them ideal for various applications. They are commonly used in cutting and shaping materials such as metal, wood, and plastic. The high-quality cement carbide material ensures that these rods can withstand the toughest conditions and provide efficient and precise performance. With their superior strength and reliability, cement carbide rods have become a trusted choice for professionals in the industrial machinery industry.

Conclusion

Summary of Cement Carbide Rods

Cement carbide rods are an essential component in various industrial applications. These rods are made from a combination of cement and carbide, resulting in a durable and high-strength material. The main purpose of cement carbide rods is to provide cutting and drilling tools with the necessary hardness and wear resistance. They are widely used in the manufacturing of tools for metalworking, woodworking, and mining industries. Additionally, cement carbide rods are also utilized in the construction sector for drilling and shaping concrete. Overall, these rods play a crucial role in enhancing productivity and efficiency in a wide range of industries.

Future Developments

In the future, there are several potential developments that can be expected in the field of cement carbide rods. One of the key areas of focus is improving the durability and strength of these rods, allowing them to withstand even more demanding applications. Additionally, advancements in manufacturing techniques may lead to the production of carbide rods with even tighter tolerances and higher precision. Furthermore, there is a growing interest in exploring alternative materials and compositions that can enhance the performance of cement carbide rods. These developments aim to further expand the range of applications and improve the overall performance of cement carbide rods in various industries.

Importance in Various Industries

Cement carbide rods play a crucial role in various industries due to their exceptional properties and versatility. These rods are widely used in the manufacturing and construction sectors for applications such as cutting, drilling, and shaping different materials. The hardness and durability of cement carbide rods make them ideal for heavy-duty tasks, allowing industries to improve their efficiency and productivity. Additionally, these rods are highly resistant to wear and corrosion, ensuring long-lasting performance even in harsh environments. The importance of cement carbide rods in industries cannot be overstated, as they provide the necessary tools and components for a wide range of applications.