Imagine this: you’re in the middle of a crucial DIY project, and your saw blade starts to dull. Frustration sets in as you realize you’ll need to replace the blade, delaying your progress. But what if there was a better option, a blade that stayed sharp longer and could tackle even the most challenging materials? Enter the carbide-tipped saw, the superhero of the sawing world.

What are Carbide Tipped Saws?

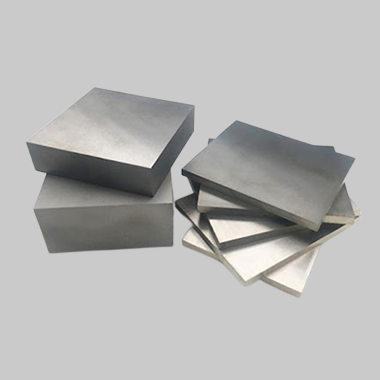

A carbide-tipped saw is a type of saw blade that features small, extremely hard tips made of tungsten carbide brazed onto a steel base. Tungsten carbide is a ceramic-like material known for its exceptional durability and resistance to wear and tear.

Here’s a fun analogy: think of a carbide-tipped saw blade like a knight in shining armor. The steel base is the knight’s sturdy suit, while the carbide tips are his unyielding sword. Together, they provide unmatched strength and resilience to conquer any cutting challenge.

Why Use a Carbide Tipped Saw?

There are several compelling reasons to choose a carbide-tipped saw over a traditional steel blade:

Carbide-tipped saw blades offer several significant advantages over traditional steel blades, making them a popular choice for professional contractors and serious DIYers alike. Here’s a closer look at the key benefits:

1. Enhanced Durability:

The primary advantage of carbide-tipped saws lies in their exceptional longevity. Carbide, a ceramic-like material composed of tungsten carbide or titanium carbide, boasts exceptional hardness, exceeding steel by a significant margin. This translates to blades that stay sharp considerably longer, resulting in:

- Reduced blade changes: This translates to significant time savings, especially during prolonged projects.

- Cost-effectiveness: Fewer blade replacements translate to lower overall tool ownership costs.

2. Remarkable Versatility:

Carbide-tipped blades excel in their ability to handle a diverse range of materials, unlike their steel counterparts that are often limited to specific materials. With the appropriate blade configuration, carbide-tipped saws can effortlessly cut through:

- Wood: Ideal for general carpentry tasks, like framing, ripping, and crosscutting lumber.

- Metal: Can effectively cut through thin metals like aluminum, copper, and even mild steel, making them suitable for plumbing and electrical work.

- Plastic: Useful for cutting various plastic materials, such as PVC pipes and sheeting.

- Masonry: Certain carbide-tipped blades are specifically designed to handle brick, concrete, and other masonry materials.

This versatility eliminates the need to switch between different blades for various tasks, streamlining the workflow and enhancing efficiency.

3. Superior Cutting Performance:

The inherent sharpness of carbide tips translates into cleaner and more precise cuts compared to traditional steel blades. This is particularly beneficial for:

- Fine carpentry projects: Precise cuts are crucial for achieving flawless joints and seamless finishes in furniture making, cabinetry, and other delicate woodworking applications.

- Trimming tasks: Clean cuts minimize the need for extensive sanding or reworking, saving time and effort.

Types of Carbide Tipped Saws

Carbide-tipped saws come in various configurations to suit different needs and applications. Here’s a breakdown of the most common types:

1. Circular Saw Blades: The All-Rounders

These versatile champions reign supreme in the realm of cutting various materials using circular saws. They don a crown of diverse diameters and tooth counts, each meticulously crafted to conquer specific materials and cutting tasks. So, whether you’re taming tough lumber or tackling intricate tile work, a circular saw blade awaits your command.

2. Miter Saw Blades: Precision Personified

For those seeking unparalleled accuracy in the realm of angled cuts, miter saw blades stand tall. Designed to seamlessly integrate with miter saws, these blades boast a higher tooth count compared to their circular saw brethren. This elevated tooth count empowers them to deliver impeccably precise cuts, transforming even the most demanding projects into a symphony of clean lines and sharp angles.

3. Table Saw Blades: Masters of Woodworking

Table saw blades, as their name suggests, are specifically engineered to excel when paired with table saws. They proudly flaunt a diverse array of tooth configurations, each meticulously crafted to conquer a specific woodworking challenge. Whether you require the prowess of a ripping blade to tear through lumber with ease, the finesse of a crosscutting blade to ensure immaculate perpendicular cuts, or the finishing touch of a dedicated finishing blade, the world of table saw blades offers a solution for every woodworking need.

4. Reciprocating Saw Blades: Demolition Dynamos

When the task at hand demands raw power and the fortitude to conquer obstinate materials, reciprocating saw blades rise to the occasion. These formidable warriors are the weapon of choice for demolition projects, effortlessly slicing through tough materials like metal pipes and concrete. Their unwavering resolve makes them invaluable companions for tackling the most demanding cutting challenges.

Carbide Tipped Saw Price Range

Carbide-tipped saw blades typically cost more than standard steel blades due to the higher material and production costs. However, their extended lifespan and superior performance often make them a cost-effective choice in the long run.

Here’s a general price range for different types of carbide-tipped saw blades:

| Blade Type | Price Range |

|---|---|

| Circular Saw Blade | $20 – $100 |

| Miter Saw Blade | $30 – $150 |

| Table Saw Blade | $20 – $120 |

| Reciprocating Saw Blade | $10 – $50 |

It’s important to note that these are just estimates, and the actual price can vary depending on the specific brand, size, tooth count, and features of the blade.

Things to Consider When Choosing a Carbide Tipped Saw

Before you head out to buy a carbide-tipped saw, here are some crucial factors to consider:

Understanding Carbide-Tipped Saws:

- Function: A carbide-tipped saw is a type of saw blade equipped with teeth composed of tungsten carbide, an exceptionally hard and wear-resistant material. This design allows the blade to maintain its sharpness significantly longer compared to traditional steel blades, making it ideal for frequent cutting applications.

Choosing the Right Carbide-Tipped Saw:

- Application:

- Material Compatibility: This is the most crucial factor. Select a blade specifically designed for the materials you intend to cut most often. For example, blades meant for wood will differ from those designed for metal or masonry. Mismatched blades can quickly become dull, deliver poor cutting performance, and even pose safety hazards.

- Size:

- Blade Diameter and Arbor Size: Ensure compatibility between the chosen blade’s diameter and arbor size (the central hole) with your power saw. Using an incompatible blade can damage the saw or prevent it from functioning correctly. Refer to your saw’s manual or manufacturer’s specifications to determine the compatible blade size.

- Tooth Count:

- Impact on Cutting Speed and Finish: The number of teeth on the blade significantly affects cutting speed and finish quality. Blades with higher tooth counts (more teeth) produce cleaner, finer cuts but tend to cut slower. Conversely, blades with lower tooth counts (fewer teeth) cut faster but leave rougher finishes.

- Prioritize clean cuts: Choose a higher tooth count blade (typically 60 teeth or more) for tasks like fine woodworking or creating smooth finishes.

- Prioritize cutting speed: Opt for a lower tooth count blade (typically 24 teeth or less) for faster cuts, such as ripping lumber or making quick, rough cuts.

- Brand Reputation:

- Quality and Performance: Consider opting for blades from reputable brands known for their commitment to quality and performance. While they may cost slightly more, they are generally more durable, reliable, and deliver superior cutting results compared to lesser-known brands.

Additional Tips:

- Safety: Always wear appropriate safety gear, such as eye protection, gloves, and ear protection, while operating any power saw.

- Maintenance: Regularly clean and maintain your carbide-tipped saw blade to optimize its lifespan and performance.

FAQ

| Question | Answer |

|---|---|

| What are the disadvantages of carbide-tipped saws? | While highly durable, carbide tips can chip or break if they hit hard objects like nails or metal. They are also generally more expensive than standard steel blades. |

| Can I sharpen carbide-tipped saws? | No, carbide tips are too hard to be sharpened using conventional methods. However, some professional sharpening services |