Introduction

Definition of Carbide Hard Metal Rods

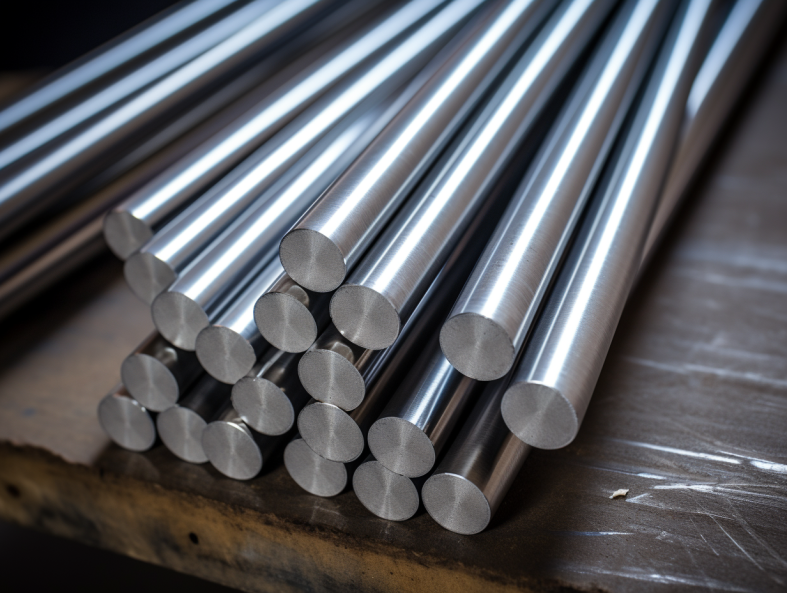

Carbide hard metal rods are specialized tools used in various industries for their exceptional hardness and durability. These rods are typically made from a combination of tungsten carbide and cobalt, which results in a material that is extremely resistant to wear and corrosion. The high hardness of carbide hard metal rods makes them ideal for applications that require cutting, drilling, and shaping of tough materials such as steel, cast iron, and stainless steel. Additionally, their superior strength allows for increased productivity and extended tool life. Overall, carbide hard metal rods are essential components in many industrial processes, providing reliable performance and efficiency.

Applications of Carbide Hard Metal Rods

Carbide hard metal rods find a wide range of applications in various industries. One of the primary uses of these rods is in the manufacturing of cutting tools. The exceptional hardness and wear resistance of carbide make it an ideal material for producing efficient and long-lasting cutting tools. Carbide hard metal rods are also used in the production of wear parts, such as nozzles, dies, and punches, where high strength and durability are required. Additionally, these rods are commonly employed in the construction industry for drilling and mining applications, thanks to their ability to withstand high temperatures and harsh conditions. Furthermore, carbide hard metal rods are utilized in the automotive industry for the production of engine components, such as valve seats and pistons, due to their excellent heat resistance and dimensional stability. Overall, the applications of carbide hard metal rods are extensive and vital in various sectors, contributing to improved productivity and performance.

Importance of Carbide Hard Metal Rods

Carbide hard metal rods play a crucial role in various industries due to their exceptional hardness and durability. These rods are widely used in applications that require cutting, drilling, or shaping tough materials like steel, wood, and concrete. The importance of carbide hard metal rods lies in their ability to provide superior performance and extended tool life, making them essential tools for professionals in machining, construction, and manufacturing. With their high resistance to wear and heat, carbide hard metal rods ensure precision and efficiency in demanding operations, resulting in improved productivity and cost-effectiveness. Whether it’s for industrial production or personal DIY projects, the use of carbide hard metal rods is paramount for achieving high-quality results and maintaining the integrity of the final product.

Composition and Properties

Materials Used in Carbide Hard Metal Rods

Carbide hard metal rods are manufactured using a variety of high-quality materials. These materials play a crucial role in determining the performance and durability of the rods. The primary material used in carbide hard metal rods is tungsten carbide, a compound known for its exceptional hardness and resistance to wear. Tungsten carbide is combined with other elements such as cobalt to enhance its strength and toughness. Additionally, carbide hard metal rods may also contain trace amounts of other elements like titanium, tantalum, or niobium, which further improve their properties. The careful selection and precise combination of these materials ensure that carbide hard metal rods exhibit superior performance and longevity in various applications.

Physical and Chemical Properties

Carbide hard metal rods possess a unique set of physical and chemical properties that make them highly desirable in various industries. These rods are known for their exceptional hardness, which allows them to withstand extreme temperatures and resist wear and tear. Additionally, carbide hard metal rods exhibit excellent corrosion resistance, making them suitable for use in harsh environments. Their high strength-to-weight ratio makes them ideal for applications that require lightweight yet durable materials. Furthermore, these rods have excellent thermal conductivity, ensuring efficient heat transfer. Overall, the physical and chemical properties of carbide hard metal rods make them indispensable in numerous industrial applications.

Advantages of Carbide Hard Metal Rods

Carbide hard metal rods offer numerous advantages in various industries. One of the key benefits is their exceptional hardness, which allows them to resist wear and abrasion even in harsh conditions. This makes them highly durable and long-lasting, reducing the need for frequent replacements. Additionally, carbide hard metal rods have excellent heat resistance, making them suitable for applications that involve high temperatures. They also exhibit superior strength and toughness, enabling them to withstand heavy loads and impacts. Moreover, these rods have excellent corrosion resistance, making them ideal for use in corrosive environments. Overall, the advantages of carbide hard metal rods make them a preferred choice for industries such as manufacturing, construction, and mining.

Manufacturing Process

Raw Material Preparation

Raw material preparation is a crucial step in the production of carbide hard metal rods. It involves carefully selecting and processing the materials that will be used to create these durable and high-performance rods. The raw materials, which typically include tungsten carbide powder and cobalt powder, are thoroughly mixed and blended to ensure a homogeneous composition. This mixture is then compacted and shaped into the desired form, such as cylindrical rods, through a process called powder metallurgy. The prepared raw materials are now ready to undergo further manufacturing processes, such as sintering and finishing, to transform them into the final carbide hard metal rods.

Mixing and Forming

Mixing and forming are crucial steps in the production of carbide hard metal rods. During the mixing process, various powders, including tungsten carbide, cobalt, and other alloying elements, are carefully blended together to create a homogeneous mixture. This ensures that the final product has the desired composition and properties. Once the powders are mixed, they are then compacted and formed into the desired shape through processes such as extrusion or pressing. These forming techniques help to further enhance the density and strength of the carbide rods, making them suitable for a wide range of applications in industries such as manufacturing, mining, and construction.

Sintering and Finishing

Sintering and finishing are crucial processes in the production of carbide hard metal rods. Sintering involves heating the raw materials at high temperatures to form a solid mass, allowing for the consolidation of the metal particles. This process helps to enhance the strength and durability of the rods. Once the sintering process is complete, the rods undergo finishing, which includes grinding, polishing, and coating. Finishing not only improves the surface quality of the rods but also ensures dimensional accuracy and uniformity. It is through these meticulous processes that carbide hard metal rods achieve their exceptional hardness, wear resistance, and overall performance.

Types of Carbide Hard Metal Rods

Tungsten Carbide Rods

Tungsten carbide rods are a type of carbide hard metal rods that are widely used in various industries. These rods are known for their exceptional hardness and durability, making them ideal for applications that require high wear resistance. The tungsten carbide composition of these rods provides excellent strength and toughness, allowing them to withstand extreme conditions and heavy-duty use. Whether it’s in the manufacturing of cutting tools, wear parts, or precision instruments, tungsten carbide rods are the go-to choice for professionals who seek reliable and long-lasting performance. With their superior properties and versatility, tungsten carbide rods play a crucial role in enhancing productivity and efficiency in countless industrial applications.

Titanium Carbide Rods

Titanium Carbide Rods are a type of carbide hard metal rods that are widely used in various industries. These rods are known for their exceptional hardness, strength, and wear resistance, making them ideal for applications that require high-performance materials. Titanium carbide rods are commonly used in the manufacturing of cutting tools, drills, and wear parts for machinery. The unique properties of titanium carbide, such as its high melting point and excellent thermal stability, make it a popular choice for demanding applications. Additionally, these rods exhibit excellent corrosion resistance, ensuring their durability and longevity. Overall, titanium carbide rods are essential materials in industries where toughness, hardness, and reliability are crucial.

Cobalt Carbide Rods

Cobalt carbide rods are a type of carbide hard metal rods that are widely used in various industries. These rods are known for their exceptional hardness and wear resistance, making them suitable for applications that require high strength and durability. Cobalt carbide rods are commonly used in the manufacturing of cutting tools, such as drills and end mills, as well as in the production of wear-resistant parts and components. With their excellent thermal stability and resistance to corrosion, these rods offer reliable performance even in challenging environments. Overall, cobalt carbide rods are an essential material for industries that demand reliable and long-lasting solutions for their machining and wear-resistant needs.

Applications

Metalworking

Metalworking is a fascinating field that involves the shaping and manipulation of various metals to create useful products. One important aspect of metalworking is the use of carbide hard metal rods. These rods are known for their exceptional hardness and durability, making them ideal for applications that require strength and resistance to wear. Whether it’s cutting, drilling, or machining, carbide hard metal rods are indispensable tools in the metalworking industry. They provide precision and efficiency, allowing craftsmen to achieve intricate designs and high-quality finishes. With their superior performance and longevity, carbide hard metal rods have become a staple in the arsenal of metalworkers worldwide.

Mining and Construction

Mining and construction industries heavily rely on carbide hard metal rods for a wide range of applications. These durable and high-performance rods are essential in various mining operations, including drilling, cutting, and crushing of rocks and ores. In construction, carbide hard metal rods are used in the production of tools and equipment for excavation, demolition, and road construction. Their exceptional hardness and wear resistance make them ideal for withstanding the harsh conditions encountered in these industries. With the increasing demand for efficient and reliable solutions, carbide hard metal rods continue to play a vital role in enhancing productivity and durability in mining and construction projects.

Woodworking

Woodworking is a versatile and rewarding hobby that allows individuals to create beautiful and functional pieces from wood. One essential tool in woodworking is carbide hard metal rods. These rods are made from a durable and strong material that is perfect for cutting and shaping wood. With carbide hard metal rods, woodworkers can achieve precise and clean cuts, resulting in high-quality craftsmanship. Whether it’s carving intricate designs or constructing furniture, carbide hard metal rods are a must-have for any woodworking enthusiast.

Conclusion

Summary of Carbide Hard Metal Rods

Carbide hard metal rods are a crucial component in various industries, known for their exceptional hardness and durability. These rods are made from a combination of tungsten carbide and cobalt, resulting in a material that can withstand extreme temperatures and resist wear and tear. The summary of carbide hard metal rods highlights their importance in applications such as metalworking, mining, and construction. These rods are commonly used for cutting, drilling, and shaping hard materials, providing precise and efficient results. With their superior strength and resistance to corrosion, carbide hard metal rods are an essential tool for professionals seeking high-performance and long-lasting solutions.

Future Trends

In the future, carbide hard metal rods are expected to revolutionize various industries. With their exceptional hardness and durability, these rods have the potential to enhance the performance and longevity of cutting tools, mining equipment, and industrial machinery. Additionally, advancements in carbide technology are likely to result in improved resistance to wear and corrosion, further expanding the applications of carbide hard metal rods. As industries continue to evolve and demand higher-performing materials, it is anticipated that carbide hard metal rods will play a crucial role in shaping the future of manufacturing and engineering.

Final Thoughts

In conclusion, carbide hard metal rods are a crucial component in various industries. Their exceptional hardness, strength, and wear resistance make them ideal for applications that require high performance and durability. Whether used in cutting tools, drilling equipment, or machinery parts, carbide hard metal rods consistently deliver superior results. Additionally, their ability to withstand extreme temperatures and corrosive environments further enhances their value. Overall, carbide hard metal rods are an indispensable material that plays a vital role in enhancing productivity and efficiency in numerous sectors.