Imagine this: you’re meticulously shaping a piece of wood on your lathe, coaxing it into a form that reflects your creative vision. Suddenly, your trusty steel cutting tool sputters and dulls, leaving behind a rough, uneven surface. Frustration sets in.

This scenario is a common hurdle for woodturners. Thankfully, there’s a game-changing solution lurking in the shadows: round carbide cutter inserts. These unassuming discs of industrial-grade tungsten carbide are poised to revolutionize your woodturning experience.

But what exactly are round carbide cutter inserts, and how can they elevate your craft? Buckle up, woodturning aficionados, because we’re about to delve into the fascinating world of these little powerhouses.

The Production Process of Round Carbide Cutter Inserts

Round carbide cutter inserts are the brainchild of a meticulous manufacturing process. Here’s a glimpse behind the curtain:

- Raw Materials: The journey begins with tungsten carbide, an incredibly hard and wear-resistant ceramic compound. This exceptional material forms the foundation of the insert’s strength and longevity.

- Powder Forming: The tungsten carbide is meticulously ground into a fine powder, ensuring a uniform consistency throughout the insert.

- Pressing and Shaping: Under immense pressure, the powder is compressed into the desired round shape of the insert. This initial shaping lays the groundwork for the insert’s final geometry.

- High-Temperature Shenanigans: The compressed powder embarks on a fiery adventure in a sintering furnace. Here, extreme heat welds the particles together, forging a rock-solid bond that grants the insert its immense strength.

- Sharpening and Finishing: Once cooled, the insert is meticulously ground and honed to achieve the precise cutting geometry. This stage dictates the insert’s cutting performance and the type of cut it excels at.

- Quality Control: No insert leaves the factory floor without undergoing rigorous quality checks. These inspections ensure each insert meets the manufacturer’s exacting standards for sharpness, consistency, and overall integrity.

The result of this intricate process is a small, unassuming disc capable of slicing through wood like butter – a testament to the ingenuity of modern engineering.

Selecting Round Carbide Cutter Inserts

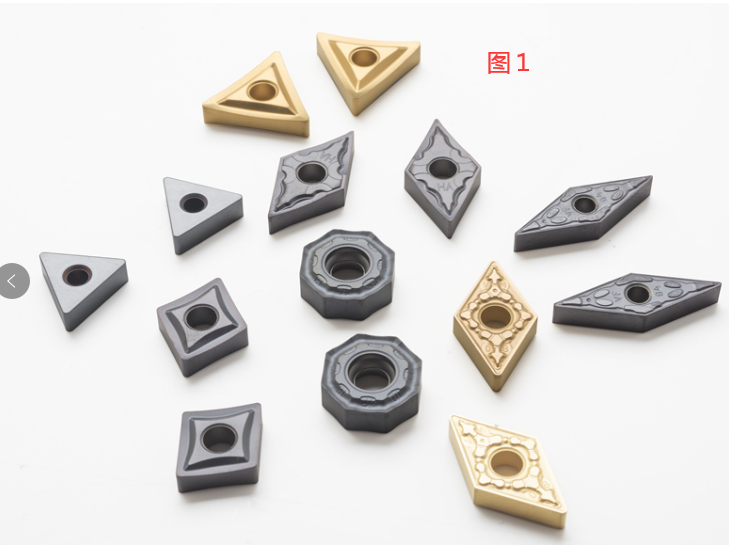

With a diverse array of round carbide cutter inserts available, choosing the right one might seem daunting. But fear not, woodturning comrades! Here’s a breakdown of key factors to consider:

1. Insert Size:

Just like Goldilocks and her porridge, you need an insert that fits your toolholder “just right.” Diameters typically range from 8mm to 16mm, so ensure compatibility with your specific holder.

2. Cutting Angle:

The cutting angle determines the type of cut the insert excels at. Flatter angles (around 30 degrees) are ideal for roughing cuts, while steeper angles (around 50 degrees) deliver smooth finishing cuts.

3. Brand and Reputation:

While tempting to grab the cheapest option, consider the reputation of the brand. Opting for established names often translates to superior quality control and longer insert lifespan.

4. User Reviews and Recommendations:

The experiences of fellow woodturners are invaluable. Seek out online reviews and recommendations to glean insights into real-world performance and user satisfaction.

Here’s a helpful analogy: Imagine selecting a paintbrush. You wouldn’t use the same brush for delicate details and broad strokes, would you? Similarly, the choice of round carbide cutter insert hinges on the specific woodturning task at hand.

Round Carbide Cutter Inserts vs. Traditional Steel Cutters

So, how do round carbide cutter inserts stack up against traditional steel cutters? Let’s break it down in a head-to-head showdown:

Round Carbide Cutter Inserts:

- Sharpsharp Sharp! These inserts boast exceptional edge retention, staying sharper for significantly longer periods compared to steel. This translates to cleaner cuts and less frequent sharpening interruptions.

- Durability Dynasty: Tungsten carbide’s inherent toughness makes these inserts incredibly resistant to wear and tear. You can expect a single insert to outperform numerous steel cutters in terms of longevity.

- Heat is No Sweat: Round carbide cutter inserts excel at high cutting temperatures, a common occurrence in woodturning. This translates to cleaner cuts and reduced burning of the wood.

Traditional Steel Cutters:

- Cost-Effective Champions: Steel cutters are generally more affordable than their carbide counterparts. This can be a deciding factor for budget-conscious woodturners.

- Sharpening Savvy: While they dull faster, steel cutters can be sharpened at home with the right tools and know-how. This allows for on-the-fly sharpening adjustments, which some woodturners prefer over relying on pre-sharpened inserts.

Making the Call:

The choice between round carbide cutter inserts and traditional steel cutters boils down to your individual preferences and priorities. Here’s a cheat sheet to guide your decision:

- Go Carbide if: You prioritize minimal sharpening interruptions, extended insert life, and exceptional cutting performance, even at high temperatures.

- Stick with Steel if: Affordability is a primary concern, and you enjoy the hands-on experience of sharpening your own tools.

Ultimately, the best way to decide is to experiment with both and see which aligns better with your workflow and budget.

Round Carbide Cutter Insert Applications

Now that you’re armed with the knowledge of how round carbide cutter inserts are made and how to choose the right ones, let’s explore their practical applications in the woodturning world:

- Hollowing: Round carbide cutter inserts excel at hollowing out bowls and vessel interiors. Their sharp edges and durability allow for smooth, efficient removal of wood, leaving behind a clean and consistent surface.

- Finishing: Steeper-angled carbide inserts are ideal for achieving a flawless finish on your woodturned projects. Their ability to hold an edge for extended periods translates to fewer tool changes and a continuous finishing process.

- Detail Work: Smaller diameter carbide inserts can be used for intricate details and delicate cuts. Their precise geometry allows for tight maneuvers and clean results, especially in areas where larger tools might struggle.

Remember, these are just a few examples. Round carbide cutter inserts are incredibly versatile tools that can be used for a wide range of woodturning tasks, from roughing out initial shapes to achieving a polished final product.

Advanced Techniques with Round Carbide Cutter Inserts

For the seasoned woodturner seeking to push the boundaries, round carbide cutter inserts unlock a world of advanced techniques:

- Shear Scraping: This specialized technique utilizes a carbide insert specifically designed for a shearing cut. It excels at removing tear-out and leaving an exceptionally smooth surface finish, ideal for high-end projects.

- Recessing Beading: By incorporating a strategically shaped carbide insert, you can create beautiful recessed beading details on your woodturnings. The insert’s precise geometry ensures clean cuts and consistent results.

- Box Cut Kontroversy: The box cut is a controversial technique in woodturning, often performed with a scraper. However, some turners swear by using a specially profiled carbide insert for box cuts, achieving clean results with minimal tear-out.

Experimentation is key to mastering these advanced techniques. With practice and the right carbide inserts, you can elevate your woodturning artistry to new heights.

FAQ

Here are some of the most frequently asked questions regarding round carbide cutter inserts:

Q: How often do I need to replace round carbide cutter inserts?

A: The lifespan of a round carbide cutter insert depends on various factors, including the type of wood you’re working with, the cutting speed, and the frequency of use. Generally, these inserts can last significantly longer than traditional steel cutters, potentially lasting through numerous projects before needing replacement.

Q: Can I sharpen round carbide cutter inserts?

A: No, sharpening round carbide cutter inserts at home is not recommended. The process requires specialized equipment and expertise. However, some manufacturers offer replacement tips for specific insert bodies, allowing you to extend the life of the insert holder.

Q: Are round carbide cutter inserts safe to use?

A: As with any power tool, safety is paramount when using round carbide cutter inserts. Always wear proper eye protection, ensure your lathe is set up correctly, and follow safe woodturning practices. The sharp edges of carbide inserts can cause serious injury if mishandled.

Q: Where can I buy round carbide cutter inserts?

A: Round carbide cutter inserts can be found at woodworking specialty stores, online retailers, and tool catalogs. Be sure to choose a reputable brand and ensure the inserts are compatible with your specific toolholder.

Conclusion

Round carbide cutter inserts are more than just a fancy upgrade; they’re an investment in your woodturning experience. Their exceptional sharpness, durability, and ability to handle high temperatures make them a valuable asset for any woodturner, from beginners to seasoned professionals.

So, the next time you find yourself yearning for cleaner cuts, longer-lasting tools, and a more efficient workflow, consider embracing the power of round carbide cutter inserts. They might just become your new favorite companions in the woodturning workshop.