Overview

When it comes to high-performance cutting and machining tools, tungsten carbide strips stand out as a top choice due to their exceptional hardness, strength, and wear resistance. Whether you’re in the manufacturing, mining, or metalworking industries, finding the right tungsten carbide strips suppliers is crucial to ensure quality and performance. In this comprehensive guide, we’ll explore everything you need to know about tungsten carbide strips, including types, applications, material properties, and how to select the best suppliers. Let’s dive in!

Understanding Tungsten Carbide Strips

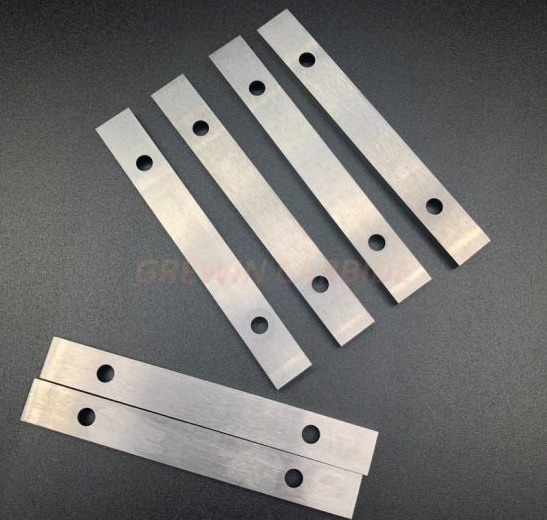

What Are Tungsten Carbide Strips?

Tungsten carbide strips are metallurgical products composed of tungsten carbide and cobalt powder, which are sintered together to form a dense and robust material. These strips are widely used in various industries for cutting, drilling, and grinding applications due to their superior hardness and durability compared to other materials.

Why Choose Tungsten Carbide Strips?

Tungsten carbide strips offer numerous advantages:

- Superior Hardness: They are much harder than steel and titanium.

- High Wear Resistance: They can withstand abrasive environments better than most materials.

- Excellent Strength: They maintain their shape and strength under high-stress conditions.

- Versatility: Suitable for a wide range of industrial applications.

Types of Tungsten Carbide Strips

| Type | Description |

|---|---|

| YG6 | Suitable for semi-finishing and roughing of cast iron and non-ferrous metals. |

| YG8 | Ideal for processing hard wood, soft wood, ferrous and non-ferrous metals. |

| YG15 | Used for impact-resistant cutting tools, drilling bits, and mining tools. |

| YG20 | Preferred for making tools that cut steel and other tough materials. |

| YG30 | Known for excellent wear resistance and high impact resistance, suitable for heavy-duty applications. |

| YWN5 | Features high toughness and wear resistance, ideal for metal cutting and wood cutting tools. |

| YWN10 | Great for applications requiring high impact and wear resistance. |

| YWN15 | Used in harsh environments, offering outstanding toughness and wear resistance. |

| ZK10UF | Ultra-fine grain carbide, perfect for precision machining. |

| ZK30UF | Ultra-fine grain, used for high-precision and high-speed cutting applications. |

Applications of Tungsten Carbide Strips

| Application | Description |

|---|---|

| Woodworking | Used in the manufacturing of woodworking tools like saw blades, cutters, and planers. |

| Metalworking | Essential in making machining tools for cutting and shaping metals. |

| Mining and Drilling | Applied in the production of drilling bits and mining tools due to their durability and resistance to wear. |

| Construction | Used in construction tools such as jackhammer bits and concrete cutting tools. |

| Textile Industry | Utilized in cutting tools for synthetic fibers and materials. |

| Paper Industry | Employed in the production of paper cutting tools and blades. |

Material Properties of Tungsten Carbide Strips

| Property | Description |

|---|---|

| Hardness | Typically measures around 85-93 HRA, depending on the grade and composition. |

| Density | Ranges between 14.5 to 15.2 g/cm³, providing a very dense and compact structure. |

| Tensile Strength | Usually around 1500 MPa, making it highly resistant to deformation under stress. |

| Compressive Strength | Can exceed 4000 MPa, offering exceptional resistance to crushing forces. |

| Young’s Modulus | Approximately 600-700 GPa, indicating a very stiff material. |

| Fracture Toughness | Typically between 10-15 MPa·m1/2, providing a good balance between toughness and hardness. |

Composition and Characteristics of Tungsten Carbide Strips

| Composition | Characteristics |

|---|---|

| Tungsten Carbide (WC) | Provides the primary hardness and wear resistance. |

| Cobalt (Co) | Acts as a binder, adding toughness and impact resistance. |

| Titanium Carbide (TiC) | Enhances wear resistance and reduces grain growth during sintering. |

| Tantalum Carbide (TaC) | Increases overall toughness and resistance to high-temperature deformation. |

| Niobium Carbide (NbC) | Adds to the hardness and thermal stability of the strip. |

Hardness, Strength, and Wear Resistance

| Grade | Hardness (HRA) | Transverse Rupture Strength (MPa) | Wear Resistance (mm3) |

|---|---|---|---|

| YG6 | 90 | 1800 | 20 |

| YG8 | 89 | 2200 | 15 |

| YG15 | 86 | 2400 | 12 |

| YG20 | 85 | 2600 | 10 |

| YG30 | 84 | 2800 | 8 |

Specifications, Sizes, Shapes, and Standards

| Specification | Size Range | Shape | Standard |

|---|---|---|---|

| Width | 3mm to 100mm | Rectangular | ISO 9001:2015 |

| Thickness | 1mm to 30mm | Square | ASTM B777-07 |

| Length | 10mm to 400mm | Circular | GB/T 18376.1-2001 |

| Grade | YG, YWN, ZK series | Custom Shapes | DIN ISO 3327 |

Top Tungsten Carbide Strips Suppliers and Pricing Details

| Supplier | Location | Price Range | Product Range | Customer Rating |

|---|---|---|---|---|

| XYZ Carbide Co. | USA | $50 – $200/kg | Full range of WC strips | ⭐⭐⭐⭐ |

| ABC Metals Ltd. | Germany | $45 – $180/kg | Specializes in YG grades | ⭐⭐⭐⭐⭐ |

| Carbide Masters | China | $40 – $150/kg | Wide variety of grades | ⭐⭐⭐⭐ |

| Global Carbides | UK | $55 – $220/kg | Custom shapes and sizes | ⭐⭐⭐⭐⭐ |

| Precision Tools Inc. | Canada | $48 – $190/kg | High precision strips | ⭐⭐⭐⭐ |

Selecting the Right Tungsten Carbide Strips

| Criteria | Considerations |

|---|---|

| Application | Identify the specific use-case (e.g., woodworking, metalworking, mining) to choose the appropriate grade. |

| Material Grade | Select a grade based on the required hardness, toughness, and wear resistance. |

| Supplier Reputation | Consider suppliers with high customer ratings and reviews. |

| Cost | Balance between cost and quality; sometimes paying a bit more ensures higher performance and durability. |

| Customization Options | Look for suppliers offering custom sizes and shapes to fit your specific needs. |

Advantages and Limitations of Tungsten Carbide Strips

| Parameter | Advantages | Limitations |

|---|---|---|

| Hardness | Exceptionally hard, providing superior cutting performance. | Can be brittle under certain conditions. |

| Wear Resistance | High wear resistance, leading to longer tool life. | May require specialized equipment for grinding and shaping. |

| Strength | Maintains strength and shape under high stress. | Higher cost compared to some alternative materials. |

| Versatility | Suitable for a wide range of applications. | Limited flexibility in certain design applications. |

| Thermal Stability | Excellent performance at high temperatures. | Can be less effective in low-temperature environments. |

How to Choose the Best Tungsten Carbide Strips Suppliers

Evaluating Supplier Quality

Choosing the right supplier can make all the difference in the performance and longevity of your tungsten carbide strips. Consider these factors:

- Quality Control: Ensure the supplier follows stringent quality control processes.

- Certifications: Look for suppliers with ISO or other relevant certifications.

- Experience: Suppliers with a long history in the industry are often more reliable.

- Customer Service: Good customer support can help resolve issues quickly and efficiently.

Comparing Prices and Services

Don’t just look at the price per kilogram; consider the overall value. Some suppliers offer additional services such as custom machining, fast shipping, and technical support, which can be invaluable.

Reading Customer Reviews

Customer reviews and testimonials can provide insight into the reliability and quality of the supplier’s products. Look for consistent positive feedback and any recurring issues mentioned by multiple customers.

FAQs

Q1: What makes tungsten carbide strips so durable?

Tungsten carbide strips are incredibly durable due to their high hardness and wear resistance, which are significantly higher than those of steel or titanium. The combination of tungsten carbide particles and cobalt binder provides a robust structure that can withstand high stress and abrasive environments.

Q2: Can tungsten carbide strips be customized?

Yes, many suppliers offer customization options for tungsten carbide strips. You can specify dimensions, shapes, and even specific grades to match your unique requirements. Customization ensures that the strips fit perfectly into your applications, enhancing performance and efficiency.

Q3: What industries use tungsten carbide strips?

Tungsten carbide strips are used across various industries, including woodworking, metalworking, mining, construction, textile, and paper industries. Their versatility and durability make them suitable for a wide range of cutting, drilling, and grinding applications.

Q4: How do I choose the right grade of tungsten carbide

The right grade depends on your specific application. For instance, YG6 and YG8 are excellent for woodworking, while YG15 and YG20 are better suited for metalworking and mining applications. Consider factors like hardness, toughness, and wear resistance when selecting the grade.strip?

Q5: Are there any environmental concerns with using tungsten carbide strips?

Tungsten carbide is generally considered safe for the environment, but the manufacturing process can have environmental impacts. Choosing suppliers who follow eco-friendly practices and adhere to environmental regulations can help mitigate these concerns.

Conclusion

Tungsten carbide strips are a vital component in many industrial applications due to their exceptional properties. Selecting the right supplier involves careful consideration of quality, customization options, pricing, and customer reviews. By understanding the types, applications, material properties, and advantages of tungsten carbide strips, you can make informed decisions that enhance your operational efficiency and product quality. Whether you’re cutting wood, machining metal, or drilling in tough environments, tungsten carbide strips offer the performance and durability you need.