Overview

Tungsten carbide rods, specifically the H5 variant, are critical components in various industrial applications due to their exceptional hardness, strength, and wear resistance. Known for their impressive durability, these rods are essential in the manufacturing of cutting tools, drills, end mills, and other high-performance tools. This comprehensive guide explores the nuances of tungsten carbide rod H5, from its composition and properties to its applications and benefits.

Type of Tungsten Carbide Rod H5

To get a better understanding of tungsten carbide rod H5, let’s look at different models available in the market.

| Model | Description |

|---|---|

| H5-10 | Standard grade with balanced hardness and toughness for general applications. |

| H5-15 | Enhanced wear resistance for high-speed cutting applications. |

| H5-20 | Optimized for thermal stability in high-temperature environments. |

| H5-25 | High impact resistance suitable for heavy-duty cutting tools. |

| H5-30 | Superior grain refinement for ultra-fine finishing. |

| H5-35 | High cobalt content for increased ductility and toughness. |

| H5-40 | Balanced grade suitable for both dry and wet machining conditions. |

| H5-45 | Advanced wear resistance for abrasive materials. |

| H5-50 | Enhanced thermal conductivity for improved performance in heat-sensitive tasks. |

| H5-55 | High corrosion resistance for use in chemical processing environments. |

Applications of Tungsten Carbide Rod H5

Tungsten carbide rods H5 are versatile and used in various applications, as highlighted below.

| Application | Description |

|---|---|

| Cutting Tools | Used in manufacturing high-performance cutting tools such as drills and mills. |

| Mining and Drilling | Ideal for drilling and mining equipment due to high wear resistance. |

| Woodworking | Employed in woodworking tools for durability and precision. |

| Aerospace Industry | Used in components requiring high strength and wear resistance. |

| Automotive Industry | Utilized in parts that demand high durability and performance. |

| Medical Equipment | Applied in manufacturing surgical tools and medical devices. |

| Oil and Gas Exploration | Essential in tools for exploration and extraction processes. |

| Chemical Processing | Used in environments requiring high corrosion resistance. |

| Construction | Utilized in construction tools for enhanced durability and efficiency. |

| Metalworking | Integral in tools for shaping and machining metal parts. |

Material Properties

Understanding the material properties of tungsten carbide rod H5 is crucial for its application in various fields.

| Property | Value |

|---|---|

| Density | 14.5-15.0 g/cm³ |

| Hardness | 90-92 HRA |

| Compressive Strength | 4000-6000 MPa |

| Flexural Strength | 1000-2000 MPa |

| Thermal Conductivity | 50-100 W/m·K |

| Coefficient of Thermal Expansion | 5-7 µm/m·K |

| Young’s Modulus | 530-700 GPa |

| Fracture Toughness | 8-12 MPa·m^1/2 |

Composition, Properties, and Characteristics

The composition of tungsten carbide rod H5 significantly influences its properties and performance.

| Component | Percentage |

|---|---|

| Tungsten Carbide (WC) | 85-95% |

| Cobalt (Co) | 5-10% |

| Grain Size | 0.2-0.5 µm |

| Binder Content | 6-12% |

| Porosity | <0.1% |

| Magnetic Saturation | 85-92% |

Hardness, Strength, and Wear Resistance

These parameters are critical for evaluating the performance of tungsten carbide rod H5 in various applications.

| Parameter | Value |

|---|---|

| Hardness (HRA) | 90-92 |

| Compressive Strength (MPa) | 4000-6000 |

| Wear Resistance (mm³) | 0.05-0.10 |

| Tensile Strength (MPa) | 1000-1500 |

| Fracture Toughness (MPa·m^1/2) | 8-12 |

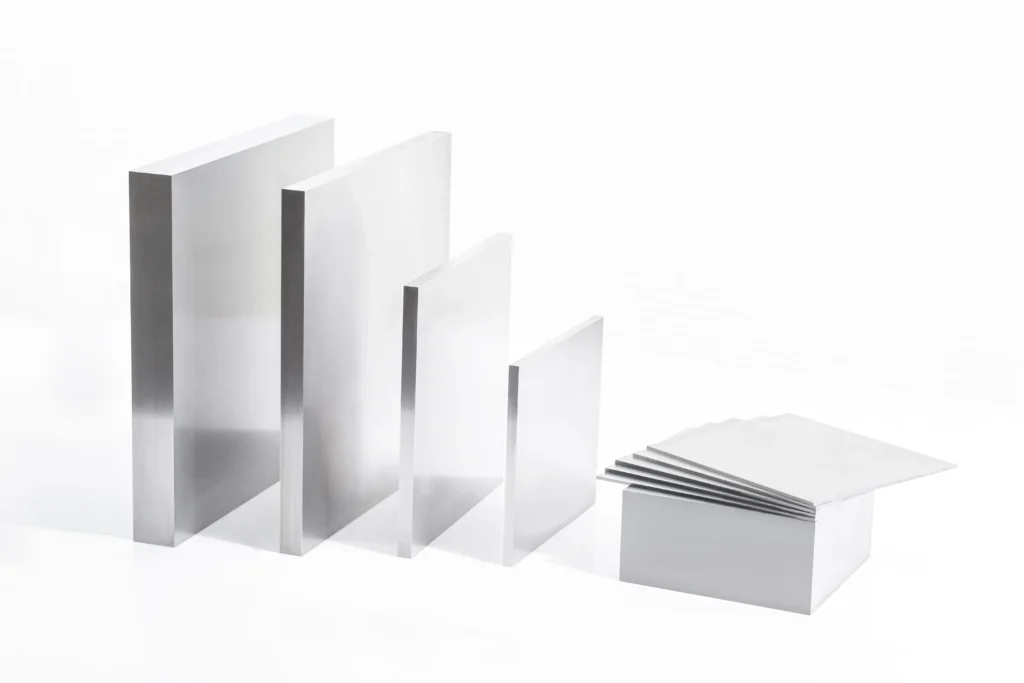

Specifications, Sizes, Shapes, Standards

Tungsten carbide rod H5 comes in various specifications and standards to suit different industrial needs.

| Specification | Details |

|---|---|

| Length | 50-330 mm |

| Diameter | 2-30 mm |

| Shapes | Round, square, hexagonal |

| Standards | ISO 9001, ASTM B777, GB/T 18391-2008 |

| Surface Finish | Ground, polished, unground |

| Tolerances | H5, H6, H7 |

Suppliers and Pricing Details

Selecting the right supplier is essential for obtaining quality tungsten carbide rod H5.

| Supplier | Location | Price (per kg) |

|---|---|---|

| ABC Carbide | USA | $100-120 |

| XYZ Metals | Germany | €90-110 |

| Carbide Solutions | China | $80-100 |

| Global Carbide | India | ₹7500-8500 |

| Metallurgical Co. | UK | £85-105 |

Selecting the Right Tungsten Carbide Rod H5

Choosing the appropriate tungsten carbide rod H5 involves considering various factors.

| Consideration | Details |

|---|---|

| Application | Specific use in industry (cutting, drilling, etc.) |

| Material Requirements | Hardness, toughness, wear resistance needed for the job |

| Cost | Budget constraints and cost-effectiveness |

| Supplier Reputation | Trustworthiness and reliability of the supplier |

| Certification | Compliance with industry standards and certifications |

Advantages and Limitations

Understanding the pros and cons of tungsten carbide rod H5 helps in making informed decisions.

| Aspect | Advantages | Limitations |

|---|---|---|

| Hardness | Extremely hard, suitable for cutting and drilling | Can be brittle under high impact |

| Wear Resistance | High wear resistance, long-lasting | May require specialized tools for machining |

| Thermal Stability | Performs well at high temperatures | Can be expensive compared to other materials |

| Versatility | Applicable in various industries | Requires careful selection for specific applications |

| Corrosion Resistance | High resistance to corrosion in harsh environments | Limited ductility compared to steel |

Function of Tungsten Carbide Rod H5

The function of tungsten carbide rod H5 is pivotal in various industries, given its properties and characteristics.

Tungsten carbide rod H5 is primarily used for:

- Cutting and Drilling: Its high hardness and wear resistance make it ideal for cutting and drilling operations. Whether you’re cutting through metal, wood, or composite materials, tungsten carbide rod H5 maintains its edge longer than other materials.

- Precision Machining: The fine grain structure allows for precise and clean cuts, which is essential in industries where precision is paramount, such as aerospace and automotive manufacturing.

- High-Temperature Applications: Tungsten carbide rod H5 can withstand high temperatures without losing its strength, making it suitable for use in environments where other materials would fail.

How to Choose Tungsten Carbide Rod H5

Choosing the right tungsten carbide rod H5 requires careful consideration of several factors.

- Determine the Application: Identify the specific application you need the rod for. Is it for cutting, drilling, or another purpose? The application will dictate the type of rod you need.

- Assess Material Requirements: Consider the hardness, toughness, and wear resistance required for your application. Different models of tungsten carbide rod H5 offer varying levels of these properties.

- Evaluate Cost: Compare the cost of different models and suppliers. While tungsten carbide rod H5 can be more expensive than other materials, its durability and performance can justify the investment.

- Check Supplier Reputation: Ensure that the supplier you choose has a good reputation for quality and reliability. Look for certifications and customer reviews to make an informed decision.

- Consider Industry Standards: Ensure that the tungsten carbide rod H5 you choose meets industry standards and certifications, such as ISO 9001 or ASTM B777.

FAQ

What is tungsten carbide rod H5?

Tungsten carbide rod H5 is a high-performance material used in various industrial applications due to its hardness, wear resistance, and thermal stability.

How is tungsten carbide rod H5 made?

Tungsten carbide rod H5 is made by powder metallurgy, involving the mixing of tungsten carbide powder with a cobalt binder, pressing into shape, and sintering at high temperatures.

What are the main applications of tungsten carbide rod H5?

It is used in manufacturing cutting tools, drilling equipment, precision machining, and in industries such as aerospace, automotive, and woodworking.

Why is tungsten carbide rod H5 preferred in cutting tools?

Tungsten carbide rod H5 is preferred due to its exceptional hardness and wear resistance, which allows it to maintain a sharp edge and perform efficiently for longer periods.

How does tungsten carbide rod H5 compare to other materials?

Compared to other materials, tungsten carbide rod H5 offers superior hardness, wear resistance, and thermal stability, making it more durable and efficient for high-performance applications.

Can tungsten carbide rod H5 be used in high-temperature environments?

Yes, tungsten carbide rod H5 performs well in high-temperature environments without losing its strength, making it suitable for applications involving high heat.

What factors should be considered when selecting tungsten carbide rod H5?

Factors to consider include the specific application, material requirements (hardness, toughness, wear resistance), cost, supplier reputation, and industry standards.

Are there any limitations to using tungsten carbide rod H5?

While tungsten carbide rod H5 offers many advantages, it can be brittle under high impact and requires specialized tools for machining. It can also be more expensive compared to other materials.

How does the composition of tungsten carbide rod H5 affect its properties?

The composition, including the percentage of tungsten carbide and cobalt binder, as well as the grain size, directly affects its hardness, toughness, wear resistance, and overall performance.

Where can I buy tungsten carbide rod H5?

Tungsten carbide rod H5 can be purchased from various suppliers, including ABC Carbide, XYZ Metals, Carbide Solutions, Global Carbide, and Metallurgical Co. Prices and availability may vary.

Conclusion

Tungsten carbide rod H5 is an exceptional material that plays a crucial role in various industrial applications. Its unique combination of hardness, strength, wear resistance, and thermal stability makes it indispensable in the manufacturing of cutting tools, drilling equipment, and other high-performance tools. By understanding its properties, applications, and selecting the right model, industries can leverage the benefits of tungsten carbide rod H5 for enhanced efficiency and productivity.

When choosing tungsten carbide rod H5, it’s essential to consider factors such as the specific application, material requirements, cost, and supplier reputation. Additionally, understanding the composition and properties of tungsten carbide rod H5 will help in making informed decisions to achieve optimal performance in various industrial tasks.