If you’ve found yourself tangled in the web of confusion when searching for the perfect tungsten carbide plate manufacturer, you’re not alone. The world of tungsten carbide plates is vast, with numerous suppliers, grades, and specifications to consider. Whether you’re an engineer, a procurement manager, or simply a curious reader, this guide is designed to untangle that web and guide you through the process of choosing the best tungsten carbide plate manufacturer for your needs.

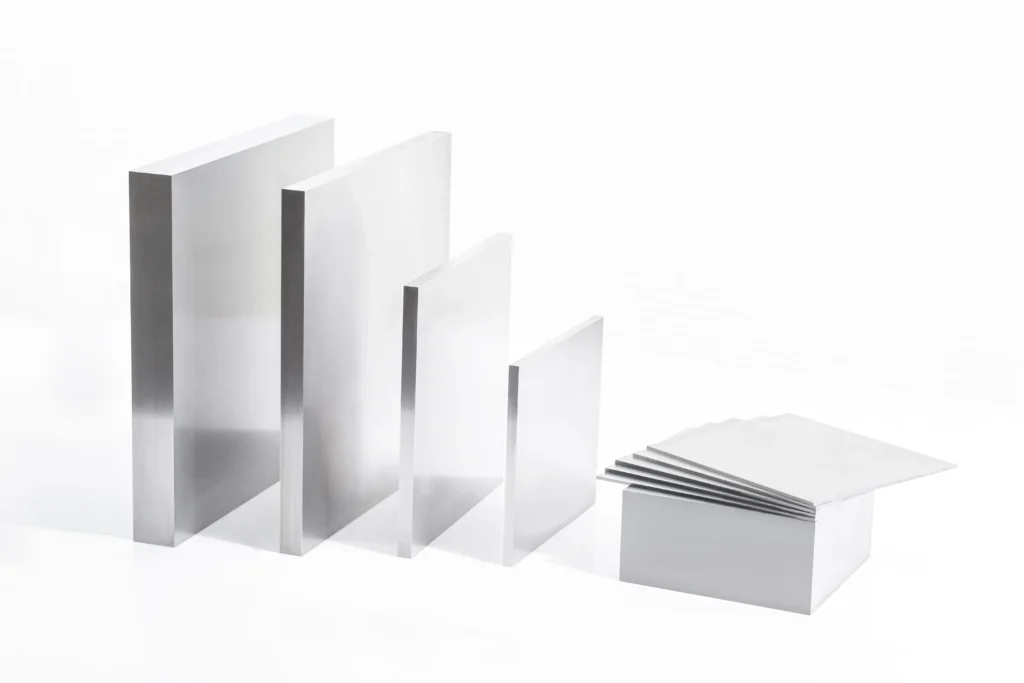

Overview: Understanding Tungsten Carbide Plates

Tungsten carbide plates are the unsung heroes in a variety of industrial applications. Known for their extreme hardness, high wear resistance, and durability, these plates are commonly used in metal cutting, mining, and construction industries, among others. But not all tungsten carbide plates are created equal. The quality and performance of these plates largely depend on the manufacturing process and the raw materials used.

In this guide, we will explore everything you need to know about tungsten carbide plates—from the types available to their applications, material properties, and even how to choose the right manufacturer. Buckle up, because we’re about to dive deep into the world of tungsten carbide!

Types of Tungsten Carbide Plates

When choosing a tungsten carbide plate, it’s essential to understand the different types available in the market. Each type is designed for specific applications, and choosing the wrong type could lead to performance issues or even failure. Below is a detailed table showcasing various types of tungsten carbide plates, along with their specific applications.

| Type of Tungsten Carbide Plate | Description | Applications |

|---|---|---|

| YG6 | High wear resistance and hardness. Moderate toughness. | Mining, drilling, and cutting tools. |

| YG8 | Higher toughness than YG6, slightly lower wear resistance. | Punching, stamping dies, and construction. |

| YG15 | High toughness, good impact resistance. | Geological exploration, coal mining, and steel processing. |

| YG20 | High hardness and moderate toughness. | Heavy-duty mining tools and wear-resistant parts. |

| YG25 | Exceptional toughness, lower hardness. | Heavy impact-resistant parts, such as crushers and dredging tools. |

| YN6 | Corrosion-resistant and wear-resistant. | Chemical industry and marine applications. |

| YN8 | High wear resistance with moderate corrosion resistance. | Oil and gas drilling, and high-pressure environments. |

| ZT35 | Ultra-fine grain size for superior wear resistance. | Precision cutting tools and high-speed machining. |

| ZT55 | Ultra-high hardness and wear resistance. | Ceramic machining and advanced composite cutting. |

| H10F | Balance of hardness and toughness, fine-grain structure. | Versatile applications including cutting, machining, and wear parts. |

Applications of Tungsten Carbide Plates

Tungsten carbide plates are used in a variety of industries. Understanding these applications will help you choose the right type of plate for your specific needs. Below is a table highlighting the primary applications of tungsten carbide plates.

| Application | Tungsten Carbide Plate Type | Benefits |

|---|---|---|

| Metal Cutting Tools | YG6, ZT35, H10F | High hardness ensures sharpness and durability. |

| Mining and Drilling Tools | YG15, YG20, YG25 | Superior toughness and wear resistance. |

| Construction | YG8, YG15, YG20 | High impact resistance and longevity. |

| Oil and Gas Exploration | YN8, YG20 | Resistance to high pressure and corrosive environments. |

| Steel Processing | YG6, YG8, YG15 | Maintains cutting edge in high-temperature conditions. |

| Ceramic Machining | ZT55, H10F | Ultra-high wear resistance for precise cuts. |

| Chemical Industry | YN6, YN8 | Corrosion resistance in harsh chemical environments. |

Material Properties of Tungsten Carbide Plates

The performance of tungsten carbide plates is heavily dependent on their material properties. These properties include hardness, toughness, wear resistance, and corrosion resistance. Below is a detailed table that presents the material properties of different types of tungsten carbide plates.

| Type | Hardness (HRA) | Toughness (MPa) | Density (g/cm³) | Wear Resistance | Corrosion Resistance |

|---|---|---|---|---|---|

| YG6 | 89.5 | 2000 | 14.8 | High | Low |

| YG8 | 88.5 | 2400 | 14.7 | Moderate | Low |

| YG15 | 87.0 | 2800 | 14.5 | Moderate | Low |

| YG20 | 85.5 | 3100 | 14.4 | Moderate | Low |

| YG25 | 83.5 | 3500 | 14.3 | Low | Low |

| YN6 | 88.5 | 1900 | 14.9 | Moderate | High |

| YN8 | 87.5 | 2200 | 14.8 | Moderate | Moderate |

| ZT35 | 92.5 | 1800 | 14.6 | Very High | Low |

| ZT55 | 93.5 | 1600 | 14.6 | Very High | Low |

| H10F | 90.5 | 2000 | 14.7 | High | Moderate |

Composition, Properties, and Characteristics

The composition of tungsten carbide plates plays a critical role in their performance. Tungsten carbide is a composite material composed of tungsten and carbon atoms, with various additives to enhance specific properties. The table below outlines the composition, properties, and characteristics of different types of tungsten carbide plates.

| Type | Composition | Properties | Characteristics |

|---|---|---|---|

| YG6 | 94% WC, 6% Co | High hardness, good wear resistance. | Ideal for metal cutting and light impact tasks. |

| YG8 | 92% WC, 8% Co | Moderate hardness, better toughness. | Suitable for stamping and construction. |

| YG15 | 85% WC, 15% Co | High toughness, lower hardness. | Best for heavy-duty mining and drilling. |

| YG20 | 80% WC, 20% Co | Moderate toughness, balanced properties. | Versatile for mining and high-pressure tasks. |

| YG25 | 75% WC, 25% Co | Very high toughness, lowest hardness. | Suitable for extreme impact applications. |

| YN6 | 94% WC, 6% Ni | High corrosion resistance, good wear resistance. | Excellent for chemical industry applications. |

| YN8 | 92% WC, 8% Ni | Balanced corrosion resistance and toughness. | Used in oil, gas, and marine environments. |

| ZT35 | 98% WC, 2% Co | Ultra-fine grain, very high hardness. | Ideal for high-speed precision machining. |

| ZT55 | 98.5% WC, 1.5% Co | Extreme hardness, lower toughness. | Best for high-wear, low-impact tasks. |

| H10F | 90% WC, 10% Co, fine grain | Balanced properties, versatile. | Suitable for a wide range of industrial applications. |

Hardness, Strength, and Wear Resistance

One of the most critical aspects of tungsten carbide plates is their hardness, strength, and wear resistance. These factors determine how well the plates will perform under stress and how long they will last. The table below compares the hardness, strength, and wear resistance of different tungsten carbide plates.

| Type | Hardness (HRA) | Compressive Strength (MPa) | Wear Resistance | Best Suited For |

|---|---|---|---|---|

| YG6 | 89.5 | 2200 | High | Cutting tools, light machining. |

| YG8 | 88.5 | 2400 | Moderate | Punching, construction. |

| YG15 | 87.0 | 3000 | Moderate | Heavy-duty drilling and mining. |

| YG20 | 85.5 | 3300 | Moderate | Mining, high-pressure environments. |

| YG25 | 83.5 | 3700 | Low | Extreme impact applications. |

| YN6 | 88.5 | 2000 | Moderate | Chemical industry, corrosion-resistant parts. |

| YN8 | 87.5 | 2200 | Moderate | Oil, gas, marine applications. |

| ZT35 | 92.5 | 1800 | Very High | Precision machining, high-speed cutting. |

| ZT55 | 93.5 | 1600 | Very High | Ceramic and composite machining. |

| H10F | 90.5 | 2400 | High | Versatile industrial applications. |

Specifications, Sizes, Shapes, and Standards

Choosing the right specifications, sizes, and shapes is crucial when selecting a tungsten carbide plate. The table below outlines the common specifications, sizes, shapes, and standards you should consider.

| Specification | Available Sizes | Shapes | Standards | Applications |

|---|---|---|---|---|

| Thickness | 0.5mm to 50mm | Rectangular, square, circular. | ISO 9001, DIN, ASTM. | General industrial applications. |

| Length | 10mm to 300mm | Rectangular, square. | GB/T, ISO, DIN. | Metal cutting, drilling. |

| Width | 10mm to 300mm | Rectangular, square. | ASTM, ISO 14001. | Mining, construction. |

| Grain Size | Coarse, Medium, Fine | N/A | ISO 9001, ASTM. | Precision machining, wear parts. |

| Surface Finish | Ground, polished, unpolished. | N/A | DIN, GB/T, ISO 9001. | Toolmaking, mold making. |

| Tolerance | +/- 0.02mm to +/- 0.1mm | N/A | DIN, ISO 2768. | High precision machining. |

Suppliers and Pricing Details

Finding the right supplier is as important as choosing the right tungsten carbide plate. The table below provides an overview of suppliers, their pricing details, and what sets them apart.

| Supplier | Price Range | Specialty | Region | Delivery Time |

|---|---|---|---|---|

| Kennametal | $150 – $500 per kg | High-performance cutting tools. | North America | 2-4 weeks |

| Sandvik | $200 – $600 per kg | Mining and construction tools. | Europe | 3-6 weeks |

| Ceratizit | $180 – $550 per kg | Wear parts and industrial tools. | Global | 2-5 weeks |

| ZCCCT | $120 – $400 per kg | Cost-effective carbide plates. | Asia | 3-8 weeks |

| Guhring | $170 – $500 per kg | Precision machining tools. | Europe | 3-5 weeks |

| Sumitomo Electric | $200 – $600 per kg | Advanced material solutions. | Japan, Global | 4-6 weeks |

| Tungaloy | $180 – $550 per kg | Cutting tools and mining applications. | Asia, Europe | 3-7 weeks |

| Zhuzhou Cemented Carbide | $100 – $350 per kg | Affordable options, broad applications. | China | 4-8 weeks |

| Hyperion Materials & Technologies | $200 – $650 per kg | High wear resistance products. | North America, Europe | 2-6 weeks |

| CB-CERATIZIT | $160 – $500 per kg | Customizable solutions, wear resistance. | Europe, Global | 3-7 weeks |

How to Choose the Right Tungsten Carbide Plate Manufacturer

Choosing the right tungsten carbide plate manufacturer can make or break your project. Here are some critical factors to consider when selecting a supplier:

| Factor | What to Consider | Why It Matters |

|---|---|---|

| Reputation | Check customer reviews, industry reputation, and years in business. | A well-reputed manufacturer is likely to deliver high-quality products consistently. |

| Product Range | Look for a manufacturer with a wide range of tungsten carbide grades. | Ensures that you can get a product tailored to your specific needs. |

| Quality Control | Ask about quality control processes, certifications (ISO, DIN, etc.). | Ensures that the products meet industry standards and your requirements. |

| Customization | Check if the manufacturer offers customizable sizes, shapes, and grades. | Allows you to get a product that perfectly fits your application. |

| Pricing | Compare prices with competitors while considering quality. | Ensures you get the best value for your money. |

| Technical Support | Check if they offer technical support and consultation. | Helps you make informed decisions and troubleshoot issues. |

| Delivery Time | Consider lead times and shipping options. | Ensures that your project stays on schedule. |

| After-Sales Service | Look for warranties, return policies, and customer support. | Protects your investment and provides peace of mind. |

| Sustainability | Check if the manufacturer adheres to sustainable and ethical practices. | Aligns with corporate social responsibility goals and ensures long-term viability. |

Advantages and Limitations of Tungsten Carbide Plates

Like any material, tungsten carbide plates have their pros and cons. Understanding these can help you make an informed decision about whether tungsten carbide is the right choice for your application.

| Advantages | Limitations |

|---|---|

| Extremely Hard and Wear-Resistant | Brittle and Can Crack Under Extreme Impact |

| Long-Lasting Performance | Expensive Compared to Other Materials |

| High Resistance to Heat and Corrosion | Requires Specialized Equipment to Machine |

| Wide Range of Applications | Heavier than Some Alternatives |

| Customizable in Terms of Size and Shape | Limited Availability in Some Regions |

| Low Maintenance Requirements | Can Be Challenging to Repair if Damaged |

FAQ

Here are some common questions about tungsten carbide plates, formatted in a table for easy reading.

| Question | Answer |

|---|---|

| What is the main use of tungsten carbide plates? | Tungsten carbide plates are primarily used in metal cutting, mining, construction, and drilling. |

| How does tungsten carbide compare to steel? | Tungsten carbide is much harder and more wear-resistant than steel, but it is also more brittle. |

| Can tungsten carbide plates be customized? | Yes, most manufacturers offer customization options in terms of size, shape, and grade. |

| What are the best tungsten carbide grades for drilling? | YG15, YG20, and YG25 are ideal for drilling due to their toughness and impact resistance. |

| How do I choose the right tungsten carbide plate? | Consider factors like hardness, toughness, application, and manufacturer reputation. |

| Are tungsten carbide plates expensive? | They can be more expensive than other materials, but their durability often justifies the cost. |

| How long do tungsten carbide plates last? | Their lifespan depends on the application but generally lasts much longer than other materials. |

| What are the main disadvantages of tungsten carbide? | The primary disadvantages are brittleness and higher cost compared to other materials. |

| Where can I buy tungsten carbide plates? | You can purchase them from specialized suppliers, both online and offline, depending on your location. |

| Is tungsten carbide environmentally friendly? | Tungsten carbide is not biodegradable, but many manufacturers follow sustainable practices. |

Conclusion

Choosing the right tungsten carbide plate manufacturer is a crucial decision that can significantly impact your project’s success. By understanding the different types, applications, material properties, and suppliers, you are well on your way to making an informed choice.

Remember, it’s not just about the price—it’s about the quality, reliability, and suitability of the product for your specific needs. Consider all factors, from reputation to after-sales support, and don’t hesitate to ask manufacturers the tough questions.

So, what’s your next step? Whether you’re ready to make a purchase or still evaluating your options, keep this guide handy. It’s your roadmap to navigating the world of tungsten carbide plates, ensuring you find the best product and the best manufacturer to meet your needs.