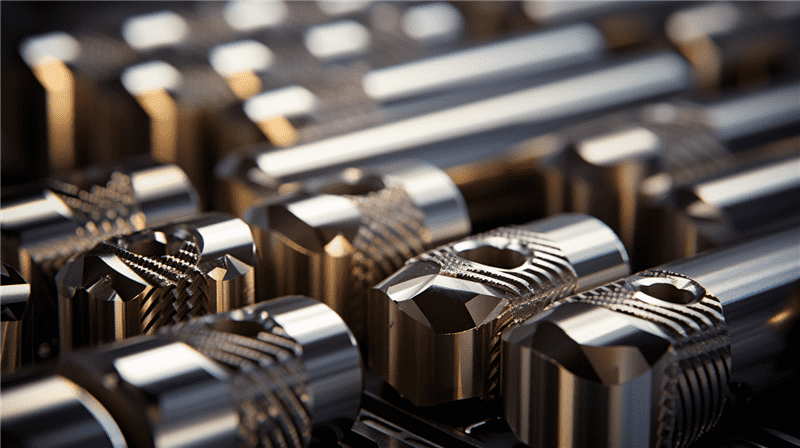

Tungsten carbide flat plates are rigid metal plates made of tungsten carbide, an extremely hard cermet material. This guide provides a comprehensive overview of tungsten carbide flat plates, their properties, manufacturing, grades, sizes, applications, and suppliers.

Overview of tungsten carbide flat plate

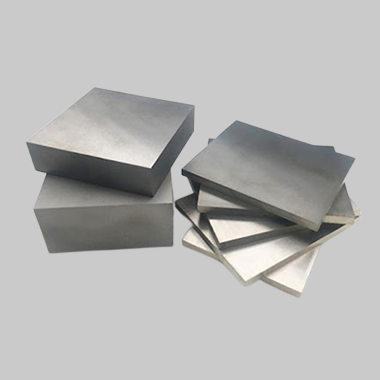

Tungsten carbide flat plates are flat pieces of tungsten carbide material, available in various sizes and thicknesses. They are extremely stiff, durable, and heat resistant plates with high compressive strength.

Tungsten carbide itself is a composite material containing tungsten metal and carbon. It is commonly referred to as a cermet (ceramic-metallic material). The most common type used in plates contains a tungsten carbide blend with 6% to 15% cobalt as a binder.

The key properties that make tungsten carbide valuable for flat plates include:

- Extreme hardness and rigidity – one of the hardest metals available

- Excellent wear resistance and durability

- High impact, bend, and crush strength

- Withstands high temperatures and thermal shock resistance

- Corrosion and chemical resistance

These properties allow tungsten carbide plates to withstand harsh conditions in critical applications across industries. The extreme hardness makes them highly wear-resistant, allowing them to outlast steel and other materials.

Tungsten carbide flat plates are most commonly used to line equipment or create very durable work surfaces. Common examples include:

- Lining for ball mills, crushers, centrifuges and reactors

- Hard surfacing for pumps, valves, pipes, and chutes

- Precision equipment beds in machining

- Dies for extrusion, stamping and wire drawing

- Components in mining and drilling tools

Continuous innovation in tungsten carbide technology allows creating grades optimized for factors like toughness, strength, or specific operating conditions.

Composition of Tungsten Carbide Flat Plates

Tungsten carbide used in plates contains:

- 85% to 95% tungsten carbide (WC) providing the hardness and wear resistance

- 5% to 15% cobalt (Co) as the ductile metallic binder that holds the tungsten carbide together

The cobalt content determines properties like fracture toughness and wear resistance. Lower cobalt WC grades have higher hardness and wear resistance but are more brittle. Higher cobalt WC grades are tougher but slightly less hard and abrasion resistant.

Typical tungsten carbide blend used in plates:

| Composition | Range |

|---|---|

| Tungsten Carbide (WC) | 85-95% |

| Cobalt (Co) binder | 5-15% |

The WC starting powder size used also affects the material properties achieved. Smaller WC grain sizes generally increase hardness and abrasion resistance.

The tungsten carbide blend is formed and sintered using specialized powder metallurgy techniques to create the finished plate product.

Properties of Tungsten Carbide Flat Plates

Physical properties:

| Property | Value |

|---|---|

| Density | 14.95 to 15.1 g/cm3 |

| Melting point | 2870°C |

| Modulus of elasticity | 520 to 630 GPa |

| Poisson’s ratio | 0.22 to 0.24 |

| Shear modulus | 262 GPa |

| Electrical resistivity | 25 to 35 μΩ.cm |

| CTE | ~4.6 μm/m-K |

Mechanical properties vary based on cobalt content and carbide grain size:

| Property | Range |

|---|---|

| Hardness | 86 to 93 HRA (~2500 HV) |

| Compressive strength | 1.9 to 6.8 GPa |

| Transverse rupture strength | 600 to 3100 MPa |

| Fracture toughness (K1C) | 7 to 30 MPa√m |

Key characteristics:

- Extremely hard – up to 2500 Vickers when cobalt is 6 to 10%

- Very rigid with high Young’s modulus – minimal deflection

- Withstands up to 1200°C without oxidation

- Chemically inert and corrosion resistant

Tungsten Carbide Plate Grades

Many tungsten carbide grades exist for plates, categorized by properties like hardness, toughness, and cobalt content. Major grade types include:

1. General purpose carbide grades

- Good combination of wear-resistance and toughness

- Cobalt ranges from 6% to 16%

- Hardness around 86 HRA; 850 to 1000 HV

- Common uses – wear parts and tooling

2. Toughened carbide grades

- Extra impact and bend strength through nickel additions

- Hardness around 84 HRA

- Used where high reliability needed

3. Micrograin carbide grades

- Carbide powder under 1 micron for maximal hardness and wear performance

- Hardness over 90 HRA; ~2500 Vickers

- Highest abrasion resistance among WC grades

- Brittle; used for shaping abrasive materials

Comparison of Major Tungsten Carbide Plate Grades

| Grade Type | Hardness Range | Cobalt Content | Key Features |

|---|---|---|---|

| General Purpose | 86 to 88 HRA | 6-10% | Good all-round wear performance |

| Toughened | 82 to 85 HRA | 8-12% Ni additives | Increased toughness and bend strength |

| Micrograin | Up to 93 HRA | 6-8% | Maximum wear performance for shaping abrasive materials |

Tungsten Carbide Flat Plates Specifications

Tungsten carbide flat plates are available stocked or custom-manufactured in various sizes and dimensional tolerance grades – covering hundreds of carbide specifications.

Plate Sizes

Available in metric and imperial sizes, up to 2000 x 1000 mm plates. Standard thickness range from 2 mm to 75 mm. Common sizes include:

- 50 x 50 mm

- 100 x 100 mm

- 150 x 150 mm

- 200 x 200 mm

- 300 x 300 mm

- 500 x 500 mm

Custom plates can be manufactured in any required length, width, and thickness combination.

Dimensional Tolerances

Plates usually supplied to tolerance grades ranging from precision ground as fine as +/- 0.02 mm to more relaxed +/- 0.50 mm tolerance on dimensions. Specialtolerance grades include:

- Grade G (Precision) – +/- 0.013 mm

- Grade S or B – +/- 0.05 mm

- Grade A – +/- 0.1 mm

- Grade GP – +/- 0.50 mm

The grade affects pricing – tighter the tolerance grade, the higher the price. Dimensional tolerance impacts suitability of plates for precision equipment applications.

Manufacturing Process

Tungsten carbide flat plates are manufactured through powder metallurgy techniques and sintering:

Steps:

- Blend tungsten carbide powders and cobalt together

- Press compound into “green” preform through cold isostatic pressing

- Sinter preform at 1400°C to 1500°C in vacuum atmosphere

- Anneal carbide plate for optimal combination of hardness and toughness

- Machine plates to final dimensions and grind surface

- Qualitative tests check hardness, microstructure, dimensions, flaws

- Final visual inspection before shipment

The powder metallurgy method allows complex tungsten carbide geometries to be mass produced. It yields consistent properties part-to-part.

Tungsten Carbide Flat Plates Applications and Uses

Thanks to exceptional hardness, wear performance, and thermal resistance – tungsten carbide flat plates have diverse industrial uses, including:

Wear and abrasion applications:

- Hard surfacing for pumps, valves, pipes carrying abrasive slurries

- Chute, hopper, screw conveyor linings

- Liners for crushers, pulverizers, centrifuges, reactors

- Rollers for rolling mills

- RVSP tooling

Precision equipment:

- Beds for precision grinding machines

- Bases for coordinate measuring machines

- Precision machine slide-ways

Metal processing:

- Extrusion dies for non-ferrous metals

- Drawing dies for copper and aluminum wire

- Stamping dies

Mining and drilling

- Rock drill guides and anchors

- Nozzle inserts

Electronics

- Carrier plates for PCB drilling machines

- Wafer conveyors

Comparison of Major Application Areas for Tungsten Carbide Plates

| Industry | Key Applications | Demand Drivers |

|---|---|---|

| Mining | Machinery linings, tooling | Wear performance |

| Metal Processing | Extrusion dies, stamping | Hardness, temperature resistance |

| Food Processing | Mill liners, conveyors | Abrasion and chemical resistance |

| Oil & Gas | Valves, pumps | Wear and corrosion resistance |

| Aerospace | Grinding beds, machining | Dimensional accuracy, surface finish |

Suppliers and Pricing

Carbide flat plates can be purchased from specialty suppliers focused on tungsten carbide machine parts. Online retailers also stock popular plate sizes.

Typical pricing range:

US$60 – US$250 per plate for 50 x 50 x 10 mm plates, depending on grade and tolerance. Low-volume retail prices are higher.

Major global suppliers

| Company | HQ Location |

|---|---|

| Tunco Manufacturing | USA |

| Midwest Tungsten Service | USA |

| Federal Carbide Company | USA |

| Ceratizit Group | Luxembourg |

| Sandvik | Sweden |

Buying plates from leading manufacturers ensures reliable quality standards. Some offer further value-added services like precision grinding and custom manufacturing.

Cost drivers:

- Tolerance grade – precision grinding increases price

- Quantity and size – larger bulk orders are cheaper per piece

- Grade selection – premium micrograin grades are higher priced

- Additional fabrication – extra processing means higher cost

Price Optimization Tips

- For typical tooling uses, a standard grade offers the best value

- Buy the largest sizes usable for lower price per piece

- Where possible, adjust designs to use standard plate sizes

- For light precision work, a Grade B tolerance often suffices

Comparative Analysis

vs Steel:

- Much higher hardness and wear performance

- More rigid and stable under force

- Withstands higher operating temperatures

- More chemically resistant and inert

- Significantly more expensive material

vs Tungsten alloy plates

- 2x harder than pure tungsten plate

- Much higher temperature rating – over 1200°C

- Superior wear characteristics

- Easier to machine to fine tolerances

- Less heavy for a given plate size

vs Silicon carbide plates:

- Very similar hardness and chemical resistance

- Comparable wear rates in abrasive environments

- Less prone to brittle fractures under impact

- Requires high-precision manufacturing

- Silicon carbide offers higher temperature rating

Pros and Cons

| Advantages | Disadvantages |

|---|---|

| Exceptional hardness and rigidity | Expensive material |

| Extreme wear and abrasion resistance | Low grade toughness; brittle |

| Withstands high temperatures | Heavy density plates |

| Chemically inert and stable | Challenging to manufacture and machine |

| Dimensional stability under load | Low thermal shock resistance when bare |

| Consistent material properties | Sensitive to cobalt leaching in use |

Ideal for:

- Extremely abrasive environments

- Precision equipment beds

- Common tooling applications

Not recommended for:

- High temperature fatigue conditions

- Highly corrosive chemical processes

- Applications prone to sudden impact loads

FAQ

Q: What thickness tungsten carbide plate should be used to line a crusher?

A: For crusher linings, tungsten carbide plate thicknesses between 18 mm to 28 mm are typical based on the machine size and feeds. Thinner plates experience rapid wear. Overly thick plates are uneconomical.

Q: Can tungsten carbide flats be welded or brazed?

A: Tungsten carbide itself cannot be directly brazed or welded. Plates are often vacuum brazed to a steel backing or other substrate as an assembly. Special low-temperature brazes formulated for carbide joining must be used.

Q: Are tungsten carbide plates ok to use in acids?

A: Tungsten carbide itself has excellent corrosion resistance and shows negligible attack from most mineral acids. However, prolonged exposure can lead to preferential cobalt binder leaching which weakens the internal structure. Some loss of structural strength is expected over years of acid service.

Q: What causes cracking in tungsten carbide plates?

A: Internal cracks or outright fractures in tungsten carbide are usually caused by either material defects from manufacturing or by mechanical damage from use. Defects include void formations during sintering or cobalt pool formation. Mechanical damage can happen from sudden high loads exceeding the relatively low fracture toughness. Thermal shock during heating also frequently causes surface cracking.

Q: Can tungsten carbide flats be reused or recycled?

A: Used tungsten carbide flats can potentially be salvaged and recycled. Items can be sorted by grade and rebuilt into fresh plates using specialized re-pressing and re-sintering methods. This reclamation process helps recover the expensive tungsten content for reuse. However, properties degrade with each recycle cycle.