Introduction: Where Accuracy Reigns Supreme

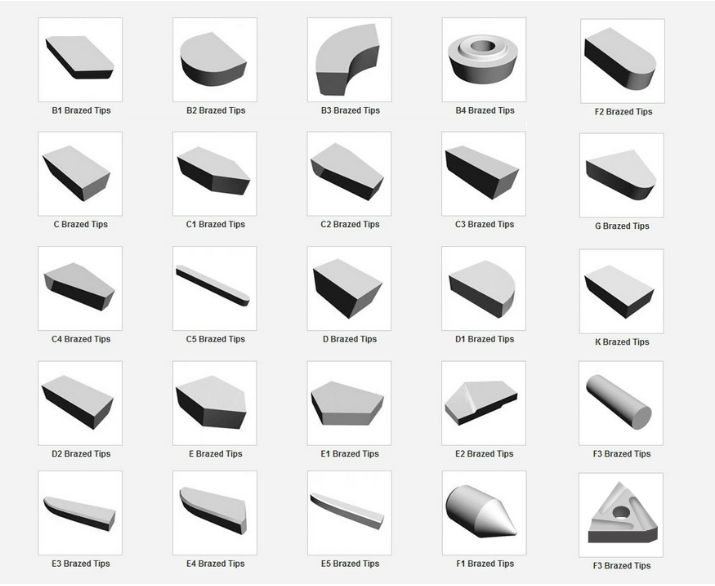

In the intricate world of machining, where thousandths of an inch can make or break a component’s functionality, precision is paramount. Enter Type F carbide brazed tips, the unsung heroes of the machining world, meticulously engineered to deliver exceptional accuracy and surface finish in demanding finishing and semi-finishing operations.

This article delves into the realm of Type F carbide brazed tips, exploring their unique characteristics, advantages, and the reasons why they’re the go-to choice when achieving tight tolerances and flawless surfaces is non-negotiable.

The Pursuit of Perfection: The Role of Finishing and Semi-Finishing

From Rough to Refined: The Stages of Machining

Machining operations typically involve a progression from roughing to finishing:

- Roughing: The initial stage, focused on removing large amounts of material quickly to achieve the approximate shape and dimensions of the workpiece.

- Semi-Finishing: An intermediate stage that bridges the gap between roughing and finishing, further refining the workpiece’s geometry and surface quality.

- Finishing: The final stage, dedicated to achieving the desired dimensional accuracy, surface finish, and overall quality of the finished component.

Type F carbide brazed tips excel in the realm of finishing and semi-finishing, where:

- Tight Tolerances: Maintaining dimensional accuracy within thousandths of an inch is crucial for proper component fit, function, and assembly.

- Superior Surface Finish: Achieving smooth, defect-free surfaces is essential for aesthetic appeal, reducing friction and wear, and enhancing corrosion resistance.

Type F Carbide Brazed Tips: Precision Engineered for Perfection

The Anatomy of Accuracy and Surface Fidelity

Type F carbide brazed tips are meticulously designed for finishing and semi-finishing operations, characterized by:

- Sharp Cutting Edges: Often featuring a combination of positive and negative rake angles, Type F tips prioritize sharp cutting edges to minimize cutting forces and achieve smooth, precise cuts that result in exceptional surface finishes.

- Small Nose Radii: The small nose radius on Type F tips allows for:

- Fine Surface Detail: Accurately machining delicate features and achieving tight radii on the workpiece.

- Minimized Scalloping: Reducing the visible scallops or ridges that can occur on contoured surfaces, especially when using larger diameter tools.

- Fine-Grained Carbide Grades: Type F tips typically employ fine-grained carbide grades with high hardness and wear resistance. These grades:

- Maintain Sharp Cutting Edges: Essential for achieving consistent accuracy and surface finish throughout the finishing process.

- Minimize Cutting Edge Wear: Reducing the need for frequent tool changes and ensuring predictable, high-quality results.

Advantages of Type F Carbide Brazed Tips in Finishing and Semi-Finishing

The Pursuit of Precision and Surface Excellence

The meticulous design and material properties of Type F carbide brazed tips translate into several key advantages:

- Exceptional Dimensional Accuracy: Their sharp cutting edges and fine-grained carbide grades enable the achievement of tight tolerances, ensuring components meet stringent dimensional requirements.

- Superior Surface Finishes: The combination of sharp cutting geometry, fine-grained carbide, and minimized cutting forces results in exceptionally smooth, defect-free surfaces.

- Extended Tool Life in Finishing Operations: While not subjected to the same heavy cutting forces as roughing tips, Type F tips still benefit from wear-resistant carbide grades, providing extended tool life, especially in finishing operations where cutting parameters are typically moderate.

- Versatility in Precision Machining: Type F tips are suitable for a wide range of finishing and semi-finishing operations, including fine milling, contouring, profiling, and finishing turns.

Applications of Type F Carbide Brazed Tips

Where Precision and Surface Quality are Paramount

Type F carbide brazed tips excel in applications where achieving tight tolerances and superior surface finishes is critical:

- Mold and Die Making: Machining intricate cavities, cores, and ejector pin holes in molds and dies used for producing plastic parts, rubber components, or metal castings.

- Aerospace Manufacturing: Producing critical components with tight tolerances and smooth surfaces, essential for aerodynamic performance, fuel efficiency, and structural integrity.

- Medical Device Manufacturing: Creating intricate features and smooth finishes on medical implants, surgical instruments, and other precision medical devices where biocompatibility and surface quality are crucial.

- Optical Components: Machining lenses, mirrors, and other optical components with extremely tight tolerances and smooth surfaces to ensure proper light transmission and reflection.

Choosing the Right Type F Carbide Brazed Tip: Factors to Consider

Fine-Tuning Your Tooling Selection for Precision Finishing

Selecting the optimal Type F carbide brazed tip involves carefully evaluating:

- Workpiece Material: The material’s hardness, abrasiveness, and thermal properties are crucial factors in determining the appropriate carbide grade and coating.

- Surface Finish Requirements: The desired surface finish, often specified in terms of Ra (roughness average) or Rz (average peak-to-valley roughness), is a primary factor in tip selection.

- Tolerance Requirements: The required dimensional tolerances influence the choice of tip geometry and cutting edge preparation.

- Machining Operation: The specific finishing or semi-finishing operation, such as fine milling, contouring, or finishing turns, influences the choice of tip geometry and size.

- Machine Tool Capability: The rigidity and precision of the machine tool can impact the achievable surface finish and tolerances.

Type F Carbide Brazed Tip Selection: A Simplified Guide

To assist in the selection process, here’s a table summarizing typical applications and considerations for different Type F tip geometries:

| Type F Tip Geometry | Typical Applications | Key Considerations |

|---|---|---|

| Round Insert with Small Nose Radius | General-purpose finishing, contouring, profiling | Provides a good balance of sharpness and strength for a wide range of applications |

| Square Insert with Sharp Corners | Finishing flat surfaces, shoulder milling | Offers sharp corners for precise 90-degree shoulders and flat surfaces |

| Diamond Insert with Sharp Point | Engraving, fine detail machining, intricate mold work | Offers exceptional sharpness for the finest details and tightest radii |

Frequently Asked Questions about Type F Carbide Brazed Tips

Q1: Can Type F carbide brazed tips be used for roughing operations?

A1: Type F tips are not designed for roughing and their use in such applications is not recommended. Their sharp cutting edges and fine-grained carbide grades are optimized for finishing and precision machining, not heavy material removal.

Q2: What are the signs of wear on a Type F carbide brazed tip?

A2: Common wear signs include rounding of the cutting edge, wear on the rake or flank face, and built-up edge (BUE) formation on the cutting edge. In finishing operations, wear can manifest as a deterioration of surface finish or a loss of dimensional accuracy.

Q3: How can I achieve the best possible surface finish with a Type F carbide brazed tip?

A3: Key factors include selecting the appropriate tip geometry and grade for the application, optimizing cutting parameters (using lower feeds and depths of cut), ensuring proper cutting fluid application, and maintaining a rigid machine setup.

Q4: What is the difference between a round insert and a square insert Type F tip?

A4: Round inserts with small nose radii provide a good balance of sharpness and strength for general-purpose finishing and contouring, while square inserts with sharp corners are ideal for finishing flat surfaces and creating precise 90-degree shoulders.

Q5: When would I choose a diamond insert Type F tip?

A5: Diamond inserts with sharp points offer exceptional sharpness for engraving, fine detail machining, and intricate mold work where achieving the finest details and tightest radii is paramount.