Introduction

When it comes to precision machining, cutting tools, and durable materials, solid carbide rods are a cornerstone. Their hardness, strength, and wear resistance make them indispensable in various industries, from aerospace to automotive. In this comprehensive guide, we’ll dive deep into the world of solid carbide rod manufacturers in China, exploring key details, specifications, and applications. Whether you’re sourcing these materials or simply curious, this guide has you covered.

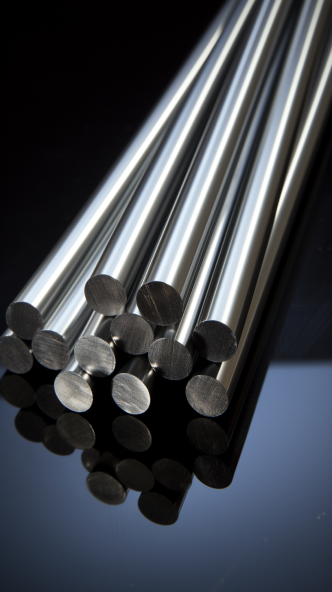

Overview of Solid Carbide Rods

Solid carbide rods are primarily used in the manufacturing of precision tools and components. They are composed of tungsten carbide and cobalt, providing a unique combination of durability and performance. The high hardness and toughness of these rods make them ideal for applications requiring wear resistance and high cutting speeds.

Types of Solid Carbide Rod Manufacturers in China

Let’s start by examining the types of manufacturers in China that produce solid carbide rods.

| Manufacturer Name | Location | Specialty | Annual Production Capacity | Notable Clients |

|---|---|---|---|---|

| Zhuzhou Cemented Carbide Group | Zhuzhou, Hunan | High-precision carbide rods | 2000 tons | Bosch, Makita |

| Xiamen Tungsten Co., Ltd. | Xiamen, Fujian | Comprehensive carbide solutions | 1500 tons | Toyota, Samsung |

| Sichuan Jinding Co., Ltd. | Chengdu, Sichuan | Custom and standard carbide rods | 1800 tons | Siemens, Caterpillar |

| Chongyi Zhangyuan Tungsten Co. | Ganzhou, Jiangxi | Tungsten carbide powders and rods | 1700 tons | Hitachi, Philips |

| China Tungsten & Hightech Co. | Zhangzhou, Fujian | High-tech carbide products | 1600 tons | LG, Panasonic |

| Hunan Kinglong New Materials | Changsha, Hunan | Advanced carbide materials | 1400 tons | GE, ABB |

| Xiamen Honglu Tungsten Molybdenum Industry | Xiamen, Fujian | Carbide rods and plates | 1300 tons | Intel, Ford |

| Nanchang Cemented Carbide Co. | Nanchang, Jiangxi | Wear-resistant carbide tools | 1200 tons | Boeing, Apple |

| Jiangxi Yaosheng Tungsten Co. | Ganzhou, Jiangxi | Innovative carbide solutions | 1100 tons | Honeywell, Schneider Electric |

| Hunan Shuangfeng Cemented Carbide | Loudi, Hunan | Cost-effective carbide rods | 1000 tons | Emerson, Sony |

Applications of Solid Carbide Rods

Solid carbide rods are versatile and find applications across a range of industries.

| Industry | Application | Advantages |

|---|---|---|

| Aerospace | High-precision cutting tools for aircraft parts | Extreme durability, precision |

| Automotive | Engine components, cutting tools | Wear resistance, high strength |

| Medical | Surgical instruments, dental tools | Biocompatibility, precision |

| Electronics | PCB drilling tools | High precision, heat resistance |

| Mining | Drilling bits, cutting tools | Wear resistance, toughness |

| Oil & Gas | Downhole tools, drilling components | High wear resistance, durability |

| Construction | Cutting tools for construction machinery | Robustness, longevity |

| Manufacturing | General machining, cutting tools | Versatility, cost-effectiveness |

| Energy | Wind turbine components, drilling tools | High strength, reliability |

| Defense | Precision components for weapons and vehicles | High durability, reliability |

Material Properties of Solid Carbide Rods

The properties of solid carbide rods are critical in determining their suitability for various applications.

| Property | Description |

|---|---|

| Hardness | Typically ranges between 85-92 HRA, providing exceptional wear resistance |

| Toughness | High fracture toughness, making them resistant to breakage under heavy loads |

| Density | Approximately 14.5-15.0 g/cm³, ensuring stability and strength |

| Thermal Conductivity | Efficient heat dissipation, crucial for high-speed machining |

| Compressive Strength | Extremely high, allowing them to withstand significant forces without deformation |

| Modulus of Elasticity | High rigidity, essential for maintaining precision during machining |

| Corrosion Resistance | Resistant to chemical corrosion, enhancing longevity in harsh environments |

Composition, Properties, and Characteristics

Understanding the composition and characteristics of solid carbide rods can help in selecting the right type for your needs.

| Element | Percentage (%) | Role |

|---|---|---|

| Tungsten (W) | 70-90 | Provides hardness and strength |

| Carbon (C) | 5-10 | Forms tungsten carbide, enhancing hardness |

| Cobalt (Co) | 5-20 | Acts as a binder, providing toughness |

| Other elements | <5 | May include tantalum, titanium for specific properties |

Hardness, Strength, and Wear Resistance

The performance of solid carbide rods is often measured in terms of hardness, strength, and wear resistance.

| Property | Metric Value |

|---|---|

| Hardness (HRA) | 85-92 |

| Compressive Strength | 6000-7000 MPa |

| Transverse Rupture Strength | 1500-2000 MPa |

| Wear Resistance | High, due to carbide composition |

Specifications, Sizes, Shape, and Standards

Solid carbide rods come in various specifications, shapes, and sizes to meet diverse application requirements.

| Specification | Range | Standard |

|---|---|---|

| Diameter | 1 mm – 100 mm | ISO 513 |

| Length | 50 mm – 500 mm | DIN 6527 |

| Shape | Round, square, rectangular | ANSI B94.19-1997 |

| Tolerance | ±0.01 mm | ISO 2768 |

Suppliers and Pricing Details

Here’s a closer look at suppliers and their pricing details for solid carbide rods.

| Supplier | Minimum Order Quantity | Price per Unit (USD) | Lead Time |

|---|---|---|---|

| Zhuzhou Cemented Carbide Group | 100 pieces | 5.00 – 20.00 | 2-4 weeks |

| Xiamen Tungsten Co., Ltd. | 200 pieces | 4.50 – 18.00 | 3-5 weeks |

| Sichuan Jinding Co., Ltd. | 150 pieces | 4.75 – 19.00 | 2-4 weeks |

| Chongyi Zhangyuan Tungsten Co. | 100 pieces | 5.10 – 20.50 | 3-5 weeks |

| China Tungsten & Hightech Co. | 200 pieces | 4.80 – 19.50 | 2-4 weeks |

How to Select the Right Solid Carbide Rod Manufacturer in China

Choosing the right manufacturer involves several key considerations.

| Consideration | Importance | Details |

|---|---|---|

| Quality Assurance | High | Look for certifications such as ISO 9001, stringent quality controls |

| Production Capacity | Medium | Ensure the manufacturer can meet your demand |

| Customization Options | Medium | Availability of custom sizes, shapes, and compositions |

| Technical Support | High | Access to expert advice and troubleshooting |

| Lead Time | High | Consider delivery times to meet your project deadlines |

| Pricing | High | Balance cost with quality and service |

Advantages and Limitations of Solid Carbide Rods

Understanding the pros and cons of solid carbide rods can help in making informed decisions.

| Aspect | Advantages | Limitations |

|---|---|---|

| Durability | Extremely durable, long-lasting | Higher cost compared to other materials |

| Precision | High precision in machining operations | Can be brittle under extreme stress |

| Versatility | Suitable for a wide range of applications | Requires specialized handling and tooling |

| Wear Resistance | Exceptional resistance to wear and tear | Limited flexibility due to high hardness |

| Heat Resistance | Performs well under high-temperature conditions | Can be difficult to work with |

FAQ

To wrap things up, here are some common questions and answers regarding solid carbide rods.

| Question | Answer |

|---|---|

| What are solid carbide rods made of? | They are primarily made of tungsten carbide and cobalt. |

| Why are solid carbide rods preferred for cutting tools? | Due to their high hardness, wear resistance, and precision. |

| Can solid carbide rods be customized? | Yes, many manufacturers offer customization options for specific needs. |

| How do I select a reliable manufacturer? | Consider factors like quality assurance, production capacity, and pricing. |

| What industries use solid carbide rods? | Aerospace, automotive, medical, electronics, mining, and more. |

Conclusion

Solid carbide rods are essential components in various high-precision and high-stress applications. China’s manufacturers are leading the charge in producing high-quality, reliable carbide rods that meet global standards. By understanding the types, applications, properties, and selection criteria, you can make informed decisions that best suit your needs. Whether you’re a manufacturer, a supplier, or an end-user, this guide aims to provide all the necessary information to navigate the world of solid carbide rods effectively.