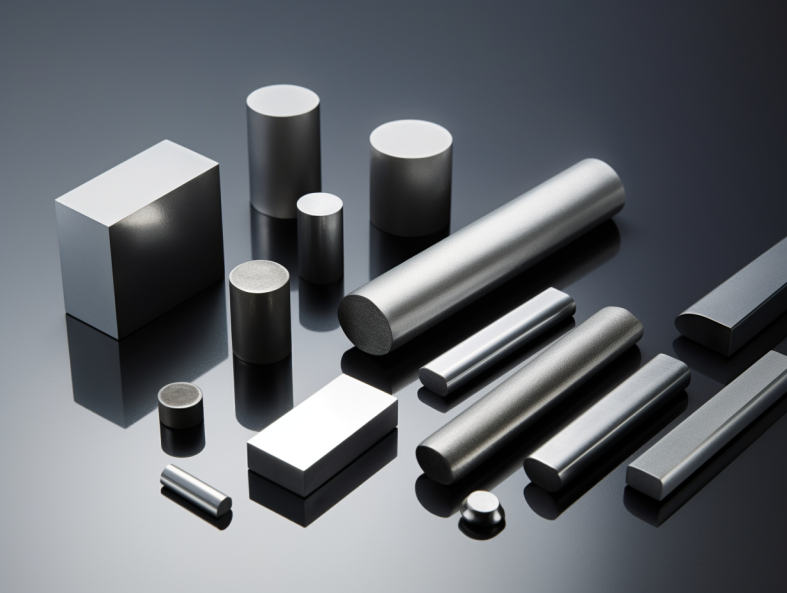

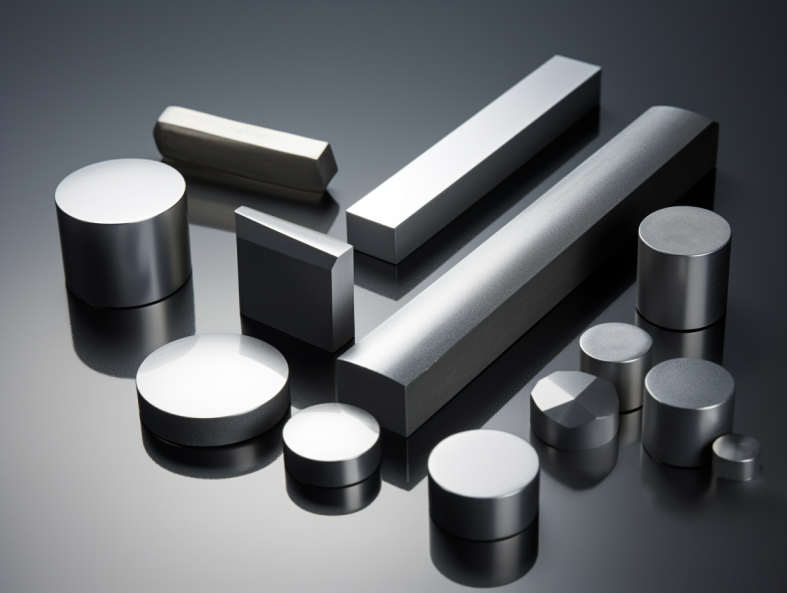

Overview of Sintered Carbide Blanks

Sintered carbide blanks refer to compacted and sintered parts made from tungsten carbide powders that are almost fully dense and dimensionally precise. Key features include:

- High hardness, wear resistance, and strength

- Sharp cutting edges can be imparted through grinding

- Can be brazed to steel bodies to make carbide cutting tools

- Rigid and dimensionally stable substrate for machining

- Enables complex geometries not possible through shaping alone

- Available in grades tailored for specific machining applications

Carbide blanks provide an economical way to manufacture indexable inserts and other cutting tool types compared to labor-intensive machining from solid carbide.

Manufacturing Process for Carbide Blanks

Carbide blanks are manufactured using powder metallurgy techniques:

- Ball milling powders to ensure uniform small particle size

- Spray drying powders into granulated forms with binders

- Compacting powder granules into a mold at high pressures

- Presintering at 1000-1300°C to impart handling strength

- Grinding blanks to precise dimensions and surface finish

- High temperature vacuum sintering at 1350-1650°C to full density

- Brazing of blank onto steel tool body

- Grinding cutting edge profile and features

Accurately controlling each production step allows sintered carbide blanks with excellent uniformity to be manufactured economically.

Types of Carbide Blank Grades

Various grades are tailored to different machining applications:

| Grade | Description | Key Properties | Typical Uses |

|---|---|---|---|

| C1-C3 | Straight tungsten carbides | Toughness | Low abrasion, aluminum, brass |

| C5-C6 | Cobalt-tungsten carbides | Wear resistance | Steels, hardened materials |

| C7-C8 | Fine grained carbides | Red hardness, strength | High-speed steels, titanium |

| C9-C10 | Coarse grained carbides | Fracture resistance | Roughing cuts and interrupted machining |

| Cermets | Titanium carbonitride alloys | High temperature strength | Hard materials at high speeds |

Proper grade selection for the work material and operation is key to maximizing tool performance and life.

Design Principles for Carbide Blanks

Several factors are important when designing carbide blanks:

- Hardness and grade must suit intended application

- Uniform, fine carbide grain size improves performance

- Generous fillet radii minimize stresses

- No sharp corners which concentrate stresses

- Appropriate clearance angles, edge preps, and chip breakers

- Must have suitable impact and fracture toughness

- Accounting for shrinkage during sintering

- Braze-ability to enable attachment to tool bodies

- Specifying dimensional tolerances for grinding

Advanced simulation tools enable virtual design optimization and process modeling to improve blank quality.

Dimensions and Tolerances for Carbide Blanks

Carbide blanks are produced in a wide range of standard and custom sizes and shapes with tight dimensional tolerances:

- Diameters: 3 mm to 150 mm+

- Thicknesses: 1 mm to 50 mm+

- Lengths: Up to 300 mm

- Shapes: Round, square, rectangular, various indexes

- Dimensional tolerances: Up to ±0.025 mm

- Flatness: <0.025 mm

- Surface finish: Up to Ra 0.2 μm

Maintaining precision tolerances enables minimal stock removal and superior finish during final grinding. Non-standard blanks can also be custom produced.

Applications of Sintered Carbide Blanks

Carbide blanks find extensive use across the following sectors:

- Cutting tools – Turning, milling, drilling, grooving, threading

- Metal forming – Punches, blanking dies

- Mining – Coal picks, drill bits

- Woodworking – Cutters, saw blades, router bits

- Composites – Cutting and milling tools

- Biomedical – Dental burrs, drills, orthopedic tools

- Jewelry – Diamond scaifes, engraving tools

- Ceramics – Cutting and slicing tools

- Glass – Cutters, drills

Carbide blanks enable economical production of precision indexable inserts and a wide range of rotary cutting tools.

Benefits of Using Sintered Carbide Blanks

Key advantages of carbide blanks:

- Cost-effective production in a range of sizes

- Excellent dimensional accuracy and repeatability

- Uniform fine carbide grain size unattainable by machining

- Achieve sharp cutting edges and intricate profiles

- Consistent performance part-to-part

- Near net shape with minimal grinding needed

- Shorter lead times compared to machining

- Easily automated mass production

- Less waste compared to machining solid carbide

- Can fabricate complex or fragile features

- Superior to cast then ground carbide parts

- Enables innovative cutting tool designs

- Simplifies indexable insert production

Carbide blanks provide substantial savings in material, machining, and manufacturing costs along with design flexibility.

Limitations of Sintered Carbide Blanks

Some drawbacks associated with using carbide blanks:

- Carbide grades and material options are limited

- Restricted to simpler blank geometries without intricate internal features

- Maximum size constrained by sintering furnace capabilities

- Not suitable for single tool prototyping or very low volumes

- Higher upfront costs for press tooling and process optimization

- Secondary grinding operations still required

- Brazing process requires expertise and adds costs

- Brittle behavior limits forming and machining options

- Advanced simulation skills needed for design

- Perceived as less prestigious than solid carbide tools

However, the benefits often greatly outweigh the limitations for most commercial cutting tool production.

Quality Control Testing for Carbide Blanks

Ensuring quality requires extensive testing of powder, green compacts, sintered blanks, and finished tools:

- Chemical composition – Confirms proper carbide types and binder content

- Particle size distribution – Optimized powder sizes for packing density

- Density analysis – Helium pycnometry and Archimedes testing verifies > 98% theoretical density

- Hardness testing – Rockwell scale confirms proper grade hardness

- Toughness – Transverse rupture strength indicates impact resistance

- Straightness – Must meet tight straightness tolerances

- Surface finish – SEM and optical inspection

- Dimensional tolerance – CMM/optical measurement of precision

- Microstructure – Carbide grain size and binder phase analysis

- Grinding performance – Cutting tests assess tool edge and geometry

Controlling every step of the process enables the delivery of high performance, reliable carbide tools.

Cost Analysis of Carbide Blanks vs Solid Carbide

The economics comparing carbide blanks and solid carbide include:

Carbide blanks:

- Lower material cost per part

- Higher manufacturing cost offset at production volumes

- Reduced grinding time and wheel costs

- Lower scrap losses during manufacturing

- 1/10th the embodied energy of machining

Solid carbide:

- Higher material cost per part

- Lower manufacturing cost at prototyping volumes

- Greater labor cost for extensive grinding

- Higher scrap losses, unused material

- No costs for tool brazing processes

Carbide blanks become cost advantageous typically beyond 1,000-5,000 parts and enable more economical tool designs through near net shape fabrication.

Selecting a Carbide Blank Supplier or Manufacturer

Key selection criteria for carbide blank suppliers:

- Proven expertise in carbide powder metallurgy

- Capability to supply desired carbide grades and grain sizes

- Dimensional accuracy and tolerances meeting requirements

- Consistency in achieving required material properties

- Range of available blank geometries and sizes

- Customization capability for unique tool designs

- Quality certifications – ISO 9001 and ISO 14001

- Inspection reports providing compliance documentation

- Technical expertise in application and material selection

- Competitive and stable pricing with prompt quoting

- Inventory availability for standard sizes to reduce lead times

- Responsiveness to requests for prototypes and samples

- Capable of managing high volume production

Established manufacturers with accredited quality systems tend to best satisfy customer needs for precision carbide blanks.

Pros and Cons of Carbide Blanks vs Alternatives

Advantages of carbide blanks:

- Substantially lower costs at production volumes

- Higher dimensional accuracy and repeatability

- Excellent surface finishes and edge sharpness

- Near net shape manufacturing reduces machining

- Finer and more uniform carbide grain size

- Allows smaller and thinner geometries

- Simpler to fabricate complex indexable inserts

- Enables innovative cutting tool designs

- Optimized grade compositions not possible in cast alloys

Disadvantages of carbide blanks:

- Higher initial process development and tooling costs

- Still requires grinding of features and cutting edges

- Limited to simpler blank forms without complex internal geometries

- Special processes needed for brazing carbide and grinding

- Perceived as less prestigious than solid carbide tools

- Range of materials not as broad as machining

In most cases, the economic and performance benefits significantly outweigh the limitations for commercial cutting tool production.

Comparison of Carbide Blanks vs 3D Printed Carbide

| Parameter | Carbide Blanks | 3D Printed Carbide |

|---|---|---|

| Manufacturing Process | Powder metallurgy compaction and sintering | Binder jet printing or laser/e-beam PBF |

| Materials | Cobalt-tungsten grades | Mixed oxides plus binders or pure tungsten |

| Part Size | Up to 300 mm dimensions | Limited to printer build chamber |

| Accuracy | Very high, ±0.025 mm | Moderate, ±0.2 mm |

| Surface Finish | Excellent | Fair to poor, requires post-processing |

| Cost Economics | Favors medium to high volumes | Better for prototyping and very low quantities |

| Production Volumes | Up to 100,000s per year | < 5,000 per year |

| Lead Times | Longer for process development | Faster for one-offs but slower for batches |

| Equipment Investment | Lower capital investment | High cost of 3D printers |

FAQ

What is the typical tolerance capability of sintered carbide blanks?

Carbide blanks can routinely achieve dimensional precision down to ±0.025 mm and ±0.05 mm for intricate features. Tolerances below ±0.01 mm are possible but with more stringent process control.

What is the cause of defects like edge chipping in sintered carbide blanks?

Insufficient impact toughness due to overly coarse carbide particles and improper blank grinding are the most common reasons for edge defects in sintered carbide blanks during subsequent machining.

How should unfinished carbide blanks be handled and stored?

As sintered carbide blanks are brittle, careful handling to avoid shocks and impacts is necessary. Blank edges should be protected and storage done in a clean, dry environment.

What limits the maximum size of sintered carbide blanks?

Uniform heating and sintering typically restricts the maximum dimensions of carbide blanks to around 300 x 300 x 50 mm. Larger presses and furnaces allow bigger blanks to be produced.

How does the cost of sintered carbide blanks compare with machining from solid carbide?

Carbide blanks are only cost-effective versus solid carbide at medium to high production volumes, typically beyond 1000 finished parts. The near net-shape and uniform properties provide significant economic benefits at scale.