Imagine a material so incredibly strong, it can tear through steel like butter. That’s the essence of round carbide rods, these unassuming cylindrical workhorses that power countless industrial applications. But beneath their seemingly simple exterior lies a world of remarkable properties and intricate engineering.

What are Round Carbide Rods?

Round carbide rods are solid cylinders composed primarily of tungsten carbide, an exceptionally hard ceramic material. Tungsten carbide itself is a combination of tungsten (a metal renowned for its high melting point) and carbon. This synergistic blend creates a material that’s:

- Extremely hard: Round carbide rods boast a Rockwell hardness (a measure of scratch resistance) exceeding 70 HRC, significantly surpassing even the toughest steels.

- Highly wear-resistant: They can withstand prolonged friction and abrasion without succumbing to wear and tear.

- Superb heat resistance: Round carbide rods maintain their strength and integrity at scorching temperatures, making them ideal for high-heat environments.

The Production Process of Round Carbide Rods

Crafting these industrial marvels involves a meticulous multi-step process:

- Powder Preparation: Tungsten and carbon powders are meticulously blended in precise ratios to achieve the desired properties.

- Molding and Pressing: The powder mixture is then shaped into a cylindrical form using high-pressure presses.

- Sintering: The molded rods undergo a high-temperature heating process (sintering) that binds the tungsten carbide particles together, forming a solid structure.

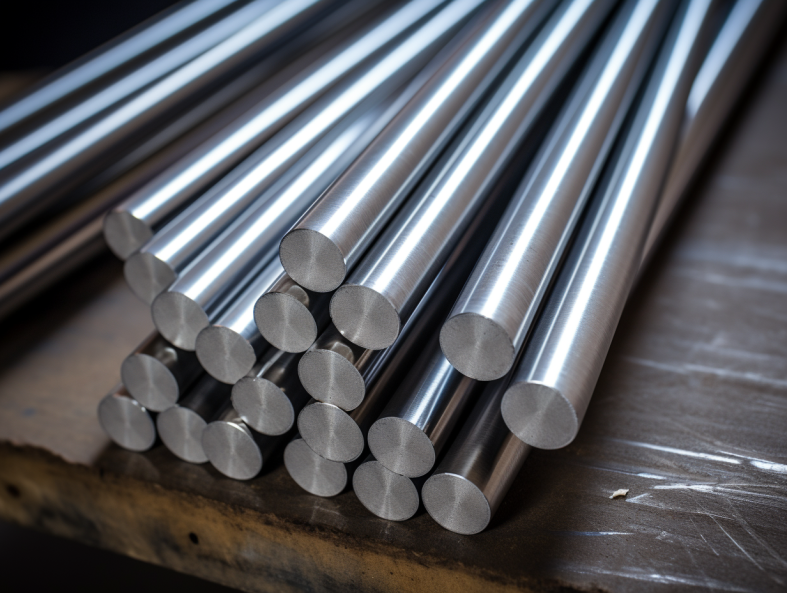

- Grinding: The sintered rods are meticulously ground to achieve the exact diameter and surface finish required for specific applications.

Selection of Round Carbide Rods

When choosing round carbide rods, several factors come into play:

- Diameter: Rod diameters range from a fraction of a millimeter to several centimeters, catering to diverse applications.

- Length: Lengths typically vary from a few centimeters to several meters, depending on the intended use.

- Grade: Different carbide grades cater to specific needs. For instance, some offer superior wear resistance, while others prioritize toughness for impact-heavy applications.

- Surface Finish: The surface finish, ranging from rough-ground to ultra-fine, influences factors like friction and chip formation during machining.

Applications of Round Carbide Rods

Round carbide rods are instrumental across a wide spectrum of industries:

- Metalworking: They’re used for cutting tools like inserts for milling cutters, turning tools, and drill bits. Their exceptional hardness allows them to efficiently machine tough metals like stainless steel and nickel alloys.

- Mining and Construction: Round carbide rods find application in drilling equipment for tough rocks and concrete due to their wear resistance.

- Woodworking: Certain grades of carbide rods are used in specialized woodworking tools for high-precision operations and extended tool life.

- Oil and Gas: Their resilience against wear and corrosion makes them suitable for downhole tools used in oil and gas exploration.

- Aerospace: Round carbide rods contribute to the creation of high-performance components in the aerospace industry due to their ability to withstand extreme conditions.

Advantages and Considerations of Round Carbide Rods

Advantages:

- Unmatched Wear Resistance: Round carbide rods significantly outperform steel and other tool materials in terms of wear resistance, leading to longer tool life and reduced downtime for replacement.

- Exceptional Hardness: Their superior hardness allows them to tackle challenging materials that would quickly dull or damage conventional tools.

- Heat Resistance: They retain their strength and dimensional stability at high temperatures, making them perfect for hot-working applications.

Considerations:

- Cost: Round carbide rods are often more expensive than conventional tool materials. However, their extended lifespan and superior performance can offset this initial cost in the long run.

- Brittleness: While incredibly hard, carbide can be brittle under certain conditions. Careful handling and proper application are crucial to avoid chipping or breakage.

Expert Insights on Round Carbide Rods

Industry experts highlight the growing demand for micro-grain carbide rods. These rods boast an even finer grain structure, translating to:

- Enhanced cutting efficiency: Micro-grain carbide allows for sharper cutting edges, leading to cleaner cuts and improved surface finishes.

- Reduced chip formation: The finer grain structure minimizes chip formation during machining, leading to smoother tool operation and less wear.

The Future of Round Carbide rods

The future of round carbide rods is bright, with ongoing research and development focused on several key areas:

- Advanced Carbide Grades: Scientists are constantly developing new carbide grades with even more impressive properties. These advancements might include:

- Increased wear resistance: Pushing the boundaries of wear resistance will further extend tool life and improve machining efficiency.

- Enhanced toughness: New formulations might offer improved resistance to chipping and breakage, particularly for applications involving high impact loads.

- Better thermal shock resistance: Carbide rods capable of withstanding even more extreme temperature fluctuations could open doors for new and demanding applications.

- Nanotechnology Integration: The exciting world of nanotechnology holds immense potential for round carbide rods. Incorporation of nanoparticles into the carbide matrix could lead to:

- Superior mechanical properties: Nanoparticles could further enhance hardness, wear resistance, and overall strength.

- Self-lubricating properties: Carbide rods embedded with lubricating nanoparticles could reduce friction and improve chip formation during machining.

- Coating Technologies: Advanced coating technologies like physical vapor deposition (PVD) are being explored to improve the performance of round carbide rods. These coatings can offer:

- Reduced friction: Coatings with low friction coefficients can minimize heat generation during machining, leading to longer tool life and improved surface finishes.

- Enhanced chemical resistance: Certain coatings can protect the carbide substrate from chemical degradation in harsh environments.

Beyond Technical Advancements: A Look at Sustainability

The future of round carbide rods also considers environmental sustainability. Manufacturers are focusing on:

- Reduced Cobalt Content: Cobalt is a critical component in traditional carbide grades, but its mining can raise environmental concerns. Research into alternative formulations with lower cobalt content, while maintaining performance, is underway.

- Recycling and Reuse: Developing efficient methods for recycling and reusing carbide scrap can minimize environmental impact and promote a more circular economy.

Conclusion

Round carbide rods are more than just industrial tools; they’re enablers of innovation. Their exceptional properties have revolutionized countless industries, and ongoing advancements promise even greater capabilities in the years to come. Whether it’s pushing the boundaries of material processing or paving the way for a more sustainable future, round carbide rods will undoubtedly remain at the forefront of industrial progress.

FAQ

Table 1: Frequently Asked Questions about Round Carbide Rods

| Question | Answer |

|---|---|

| What are round carbide rods made of? | Round carbide rods are primarily composed of tungsten carbide, a ceramic material known for its extreme hardness and wear resistance. |

| What are the benefits of using round carbide rods? | Round carbide rods offer numerous advantages, including exceptional wear resistance, superior hardness, and excellent heat resistance. These properties translate to longer tool life, improved machining efficiency, and the ability to tackle challenging materials. |

| What are some considerations when selecting round carbide rods? | Key factors to consider include diameter, length, grade (tailored for specific applications), and surface finish (impacting factors like friction and chip formation). |

| What industries use round carbide rods? | Round carbide rods find application in a wide range of industries, including metalworking, mining and construction, woodworking, oil and gas, and aerospace. |

| Are round carbide rods expensive? | While they may have a higher upfront cost compared to conventional tool materials, their extended lifespan and superior performance can lead to significant cost savings in the long run. |

| How brittle are round carbide rods? | Although incredibly hard, carbide can be brittle under certain conditions. Proper handling and application are crucial to avoid chipping or breakage. |

I hope this comprehensive guide has empowered you with valuable insights into the world of round carbide rods. Whether you’re a seasoned machinist or just beginning to explore this fascinating material, round carbide rods represent a testament to human ingenuity and a cornerstone of industrial progress.