Significance of Metric Rectangular Carbide Blanks

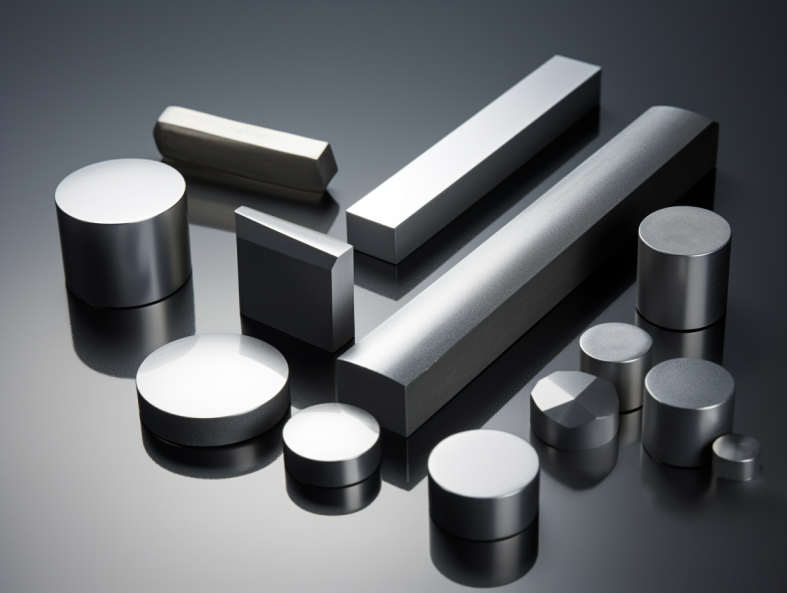

Metric rectangular carbide blanks are essential materials in manufacturing, known for their outstanding hardness and wear resistance. They are composed of carbide particles such as tungsten or titanium carbide, bound in a cobalt matrix, created through a process called liquid phase sintering. These blanks are significant due to their:

- High hardness and wear resistance

- Strength at high temperatures

- Resistance to abrasion and erosion

- Structural rigidity

- Chemical inertness

These properties make them ideal for producing cutting tools, wear parts, and custom components which are utilized across various industries including automotive, aerospace, construction, mining, agriculture, and pulp and paper. The production of these blanks involves precise manufacturing processes to ensure their quality and performance in demanding environments1.

| Grade | Composition | Characteristics |

|---|---|---|

| C1 | WC-Co | General purpose, low cost |

| C2 | WC-Co | Improved toughness and strength |

| C3 | WC-Co | Good resistance to abrasive wear |

| C4 | WC-Co | Excellent toughness and shock resistance |

| C5 | WC-TiC-Co | High hot hardness and wear resistance |

| C6 | WC-TiC-TaC-Co | Superior wear resistance, high temperature strength |

The blanks come in various specifications which can be customized to meet specific requirements, and their manufacturing is a multi-step process including milling, drying, compaction, debinding, sintering, grinding, and stringent quality control.

Cost of Metric Rectangular Carbide Blanks

The cost of metric rectangular carbide blanks can vary depending on the supplier and the specific properties of the blank, such as the grade and dimensions. For example, Element Six, a supplier located in Ireland, offers rectangular carbide blanks within the price range of $8 to $25 per piece1.

For more comprehensive pricing details, it would be beneficial to consult the guide on from Carbide Provider, as well as reach out to multiple suppliers for quotations based on the required specifications.

| Supplier Location | Price Range |

|---|---|

| Element Six (Ireland) | $8 – $25 per piece |

Types of Metric Rectangular Carbide Blanks

Metric rectangular carbide blanks come in various grades, each tailored for different applications and performance requirements. The types are distinguished by their composition and characteristics, which determine their suitability for specific uses.

| Grade | Composition | Characteristics |

|---|---|---|

| C1 | 94% tungsten carbide, 6% cobalt | General purpose, low cost |

| C2 | 91% tungsten carbide, 9% cobalt | Improved toughness and strength |

| C3 | 88% tungsten carbide, 12% cobalt | Good resistance to abrasive wear |

| C4 | 86% tungsten carbide, 14% cobalt | Excellent toughness and shock resistance |

| C5 | 86% WC, 5% titanium carbide, 9% cobalt | High hot hardness and wear resistance |

| C6 | WC+TiC+TaC+Co | Superior wear resistance, high temperature strength |

Functions of Metric Rectangular Carbide Blanks

Metric rectangular carbide blanks serve a multitude of functions in various industries due to their exceptional properties. These functions are often aligned with the production of precision tools and parts. The table below outlines the core functions served by these blanks:

| Industry | Functions Served by Carbide Blanks |

|---|---|

| Automotive | Cutting and milling tools, drawing dies, gages |

| Aerospace | Cutters, reamers, drilling and boring tools |

| Construction | Milling tools, drill bits, saw tips |

| Mining | Crushing equipment wear parts, drill bits |

| Agriculture | Tillage and harvesting tools, saw chain links |

| Pulp and Paper | Chipper and shredder knives, pulping equipment |

The key functions include manufacturing cutting tools, wear parts, and custom components that require high hardness and wear resistance. These blanks are integral in the processes of cutting, shearing, forming, and enduring high-pressure applications while maintaining dimensional stability at elevated temperatures.

Applications for Metric Rectangular Carbide Blanks

Metric rectangular carbide blanks are utilized in a variety of applications across multiple industries. Their primary use is in the manufacturing of tools and parts where exceptional hardness and wear resistance are critical. Below is a table highlighting some of their key applications across different sectors:

| Industry | Applications of Carbide Blanks |

|---|---|

| Automotive | Cutting and milling tools, drawing dies, gages |

| Aerospace | Cutters, reamers, drilling and boring tools |

| Construction | Milling tools, drill bits, saw tips |

| Mining | Crushing equipment wear parts, drill bits |

| Agriculture | Tillage and harvesting tools, saw chain links |

| Pulp and Paper | Chipper and shredder knives, pulping equipment |

Benefits of Metric Rectangular Carbide Blanks

Metric rectangular carbide blanks offer a range of benefits that can significantly enhance the efficiency and quality of manufacturing processes. Here are some of the key advantages:

| Benefit | Description |

|---|---|

| Hardness | They enable the manufacturing of tools capable of cutting through hard materials. |

| Wear Resistance | Tools made from carbide blanks last longer, reducing replacement frequency. |

| High-Temperature Strength | They maintain structural integrity even at high temperatures, crucial for high-speed operations. |

| Abrasion and Erosion Resistance | Prolonged service life in abrasive conditions. |

| Chemical Inertness | Stability in corrosive environments ensures wider applicability. |

Choosing the Right Metric Rectangular Carbide Blanks

Selecting the appropriate metric rectangular carbide blanks is crucial for optimal performance and cost-effectiveness in manufacturing. The decision should be based on the specific requirements of the application and the properties of the blank. Here’s a guide to making the right choice:

| Selection Criteria | Considerations |

|---|---|

| Application | Determine the operation type – cutting, milling, drilling, etc. |

| Material to be Processed | Consider the hardness and abrasiveness of the workpiece material. |

| Production Volume | Assess the expected volume and frequency of tool use. |

| Cost | Balance between upfront cost and the longevity of the blank. |

| Grade of Carbide | Match the carbide grade with the toughness, wear resistance, and temperature requirements of the task. |

Purchasing Metric Rectangular Carbide Blanks

When looking to purchase metric rectangular carbide blanks, there are several avenues to consider to ensure you acquire a product that meets your requirements. Here’s a structured approach to making a purchase:

| Purchase Step | Action |

|---|---|

| Research | Identify suppliers with good reputations for quality and service. |

| Specifications | Determine the grade, dimensions, and tolerances needed for your application. |

| Quotes | Obtain quotes from multiple suppliers for the best price comparison. |

| Samples | If possible, request samples to verify quality. |

| Order | Place an order with a supplier that offers the best balance of price, quality, and delivery terms. |

Product Advantages of Chinese Metric Rectangular Carbide Blanks

Chinese metric rectangular carbide blanks present several product advantages that make them competitive in the global market. Below is a table summarizing these advantages:

| Advantage | Description |

|---|---|

| Cost-Effectiveness | Often priced more competitively due to economies of scale and efficient manufacturing processes. |

| Quality | Continuous improvement in production technology ensures high-quality standards. |

| Variety | A broad range of grades and sizes to suit diverse applications. |

| Customization | Chinese manufacturers provide customization options to meet specific needs. |

| Availability | Due to large-scale production, Chinese carbide blanks are readily available. |

Determining the “best” supplier for Chinese metric rectangular carbide blanks is subjective and can depend on various factors including quality, price, customer service, and delivery times. Generally, it’s advisable to consider suppliers that have a strong reputation for consistency, reliability, and service.

To identify a supplier that fits these criteria, consider the following steps:

| Step | Action |

|---|---|

| Research | Look for suppliers with high customer satisfaction rates and industry certifications. |

| Quality Assurance | Ensure they have stringent quality control measures in place. |

| Pricing | Compare prices to ensure you are getting competitive rates. |

| Support | Check for suppliers offering robust customer service and technical support. |

| Logistics | Consider their ability to deliver products in a timely and efficient manner. |