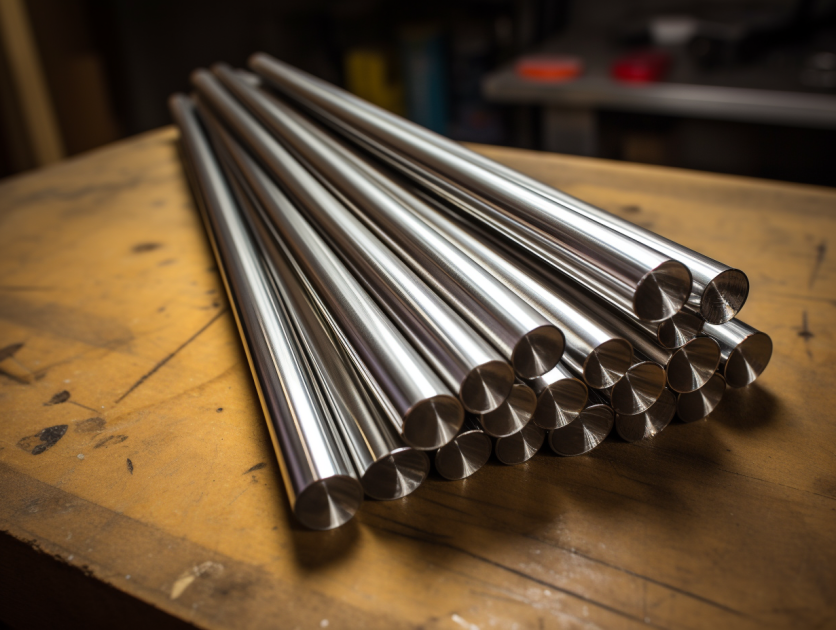

Overview of K10 Tungsten Carbide Rod

When it comes to high-performance industrial tools, K10 tungsten carbide rods are often at the forefront. Known for their incredible hardness, durability, and resistance to wear, these rods are essential in various machining and manufacturing applications. But what exactly makes K10 tungsten carbide rods so special? Let’s dive into the details, explore the types, applications, material properties, and how to select the right one for your needs

Types of K10 Tungsten Carbide Rod

K10 tungsten carbide rods come in various types, each tailored for specific applications and performance requirements. Here’s a detailed look at some popular models:

| Model | Description |

|---|---|

| K10-TC1 | General-purpose rod, suitable for a wide range of machining tasks. |

| K10-TC2 | Enhanced toughness, ideal for cutting harder materials. |

| K10-TC3 | High wear resistance, perfect for abrasive environments. |

| K10-TC4 | Specialized for drilling applications, offering excellent precision. |

| K10-TC5 | Optimized for milling, providing smooth operation and long tool life. |

| K10-TC6 | Designed for turning operations, ensuring consistent performance. |

| K10-TC7 | Premium grade, used in high-precision industries such as aerospace and automotive. |

| K10-TC8 | Suitable for high-speed machining, reducing cycle times significantly. |

| K10-TC9 | Cost-effective solution for general manufacturing applications. |

| K10-TC10 | Ultra-fine grain structure, offering superior surface finish and longevity. |

Applications of K10 Tungsten Carbide Rod

K10 tungsten carbide rods are versatile and find use in a myriad of applications. Here’s where they shine:

| Application | Description |

|---|---|

| Drilling | Used extensively in drilling due to their ability to maintain sharpness and resist wear. |

| Milling | Perfect for milling operations, offering smooth cuts and long-lasting performance. |

| Turning | Ensures consistent and precise turning operations, even with tough materials. |

| Mining | Highly resistant to wear and tear, making them ideal for mining applications. |

| Aerospace | Used in the aerospace industry for their precision and reliability. |

| Automotive | Essential in the automotive sector for manufacturing durable and precise components. |

| Woodworking | Provides excellent results in woodworking due to their sharpness and durability. |

| Medical Equipment | Used in the production of medical instruments and equipment for their precision and durability. |

| Oil and Gas | Vital in the oil and gas industry for drilling and extraction equipment. |

| Construction | Utilized in construction tools for their robustness and long life. |

Material Properties of K10 Tungsten Carbide Rod

Understanding the material properties is crucial for selecting the right K10 tungsten carbide rod for your application.

| Property | Description |

|---|---|

| Hardness | Extremely hard, typically around 90 HRA, which allows for excellent wear resistance. |

| Density | High density, around 14.5-15.1 g/cm³, contributing to its durability and strength. |

| Transverse Rupture Strength | High transverse rupture strength, usually around 2500-3000 MPa, ensuring robustness in tough applications. |

| Thermal Conductivity | Good thermal conductivity, allowing for efficient heat dissipation during high-speed operations. |

| Chemical Resistance | Resistant to corrosion and oxidation, extending the tool life even in harsh environments. |

| Fracture Toughness | Adequate fracture toughness, preventing chipping and breaking under stress. |

Composition and Characteristics of K10 Tungsten Carbide Rod

The composition of K10 tungsten carbide rods is a key factor in their performance.

| Component | Percentage | Characteristic |

|---|---|---|

| Tungsten Carbide | 94% | Provides hardness and wear resistance. |

| Cobalt | 6% | Acts as a binder, offering toughness and resistance to fracture. |

| Other Additives | Trace amounts | Enhance specific properties such as corrosion resistance and thermal stability. |

Hardness, Strength, and Wear Resistance of K10 Tungsten Carbide Rod

These attributes make K10 tungsten carbide rods a preferred choice for demanding applications.

| Attribute | Value | Description |

|---|---|---|

| Hardness | 90 HRA | High hardness ensures longevity and performance in abrasive environments. |

| Strength | 2500-3000 MPa | Exceptional strength allows for heavy-duty applications without risk of breaking. |

| Wear Resistance | Excellent | Maintains integrity and sharpness over extended use, reducing downtime and tool replacement costs. |

Specifications, Sizes, Shape, Standards of K10 Tungsten Carbide Rod

Choosing the right specifications is essential for the success of your project.

| Specification | Description |

|---|---|

| Diameter Range | 1.0 mm to 30.0 mm |

| Length | Up to 330 mm |

| Shape | Available in round, square, and rectangular profiles |

| Standards | ISO 9001:2015, ASTM B777-07, DIN 4991 |

Suppliers and Pricing of K10 Tungsten Carbide Rod

Finding reliable suppliers and understanding pricing is key to making an informed purchase.

| Supplier | Location | Price Range (per unit) | Notes |

|---|---|---|---|

| XYZ Carbide Co. | USA | $15 – $50 | Offers bulk discounts and customization. |

| ABC Metals Ltd. | UK | £12 – £45 | Known for high-quality standards. |

| Global Carbide | China | $10 – $40 | Competitive pricing and fast shipping. |

| Prime Carbide | Germany | €13 – €47 | Premium grade products with certifications. |

| Carbide Solutions | India | ₹1000 – ₹4000 | Affordable options with good quality. |

Selecting the Right K10 Tungsten Carbide Rod

Choosing the right rod involves considering various factors.

| Factor | Consideration |

|---|---|

| Application | Ensure the rod matches the specific requirements of your task. |

| Material to be Machined | Different materials require different rod properties. |

| Machine Compatibility | Verify the rod is compatible with your equipment. |

| Budget | Balance cost with performance needs. |

| Supplier Reliability | Choose suppliers with a good track record for quality and delivery. |

Advantages and Limitations of K10 Tungsten Carbide Rod

Comparing the pros and cons helps in making an informed decision.

| Aspect | Advantage | Limitation |

|---|---|---|

| Hardness | Superior hardness for excellent wear resistance. | Can be brittle if not handled properly. |

| Durability | Long-lasting, reducing the need for frequent replacements. | Higher initial cost compared to other materials. |

| Performance | Consistent and reliable performance in demanding applications. | Requires specific machinery and tools for effective use. |

FAQs

| Question | Answer |

|---|---|

| What is the primary use of K10 tungsten carbide rods? | They are mainly used in machining, drilling, and milling applications due to their hardness and durability. |

| How do I choose the right K10 tungsten carbide rod for my application? | Consider the material you are working with, the type of machining, and the specifications required. |

| What makes K10 tungsten carbide rods better than other types? | Their superior hardness, wear resistance,and durability make them ideal for high-performance applications. |

| Are there any disadvantages to using K10 tungsten carbide rods? | They can be more expensive and require specific tools and handling techniques. |

| Can K10 tungsten carbide rods be customized? | Yes, many suppliers offer customization options to meet specific needs and requirements. |

| What is the typical hardness of a K10 tungsten carbide rod? | The hardness is typically around 90 HRA. |

| Are K10 tungsten carbide rods suitable for high-speed machining? | Yes, they are excellent for high-speed operations due to their thermal conductivity and strength. |

| How do K10 tungsten carbide rods compare to steel rods? | They offer superior hardness and wear resistance but are more brittle and expensive than steel. |

| What standards do K10 tungsten carbide rods adhere to? | They typically meet standards such as ISO 9001:2015 and ASTM B777-07. |

| Where can I buy K10 tungsten carbide rods? | They can be purchased from various suppliers worldwide, including online retailers and specialty stores. |

Conclusion

K10 tungsten carbide rods are a cornerstone in industries requiring durable and reliable tools. Whether it’s for drilling, milling, or any other form of machining, their exceptional hardness, wear resistance, and overall performance make them an invaluable asset. By understanding the types, applications, and properties of these rods, you can make an informed decision and select the right product for your needs.

Remember, choosing the right K10 tungsten carbide rod involves considering your specific application, the material you’re working with, and ensuring compatibility with your machinery. With this comprehensive guide, you’re now well-equipped to navigate the world of K10 tungsten carbide rods and make the best choice for your projects.