Overview

High-quality tungsten carbide blanks are indispensable in various industries due to their exceptional hardness, durability, and versatility. As a premium supplier, we provide superior tungsten carbide blanks that cater to a wide range of applications, from cutting tools to wear-resistant parts. This comprehensive guide explores the intricate details of tungsten carbide blanks, their production, usage, market trends, and why choosing a reliable supplier like TRUER is crucial for your business success.

Detailed Introduction

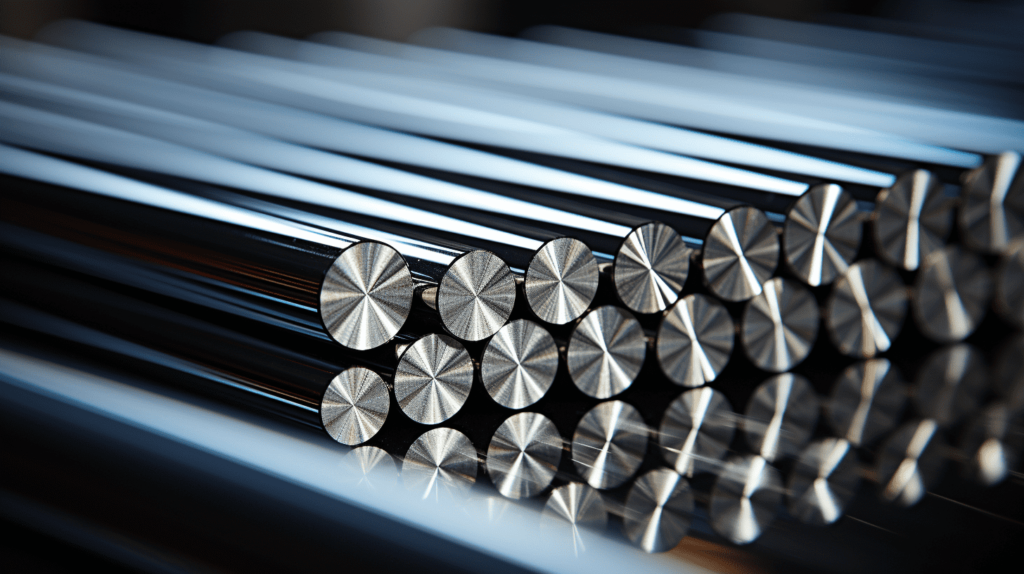

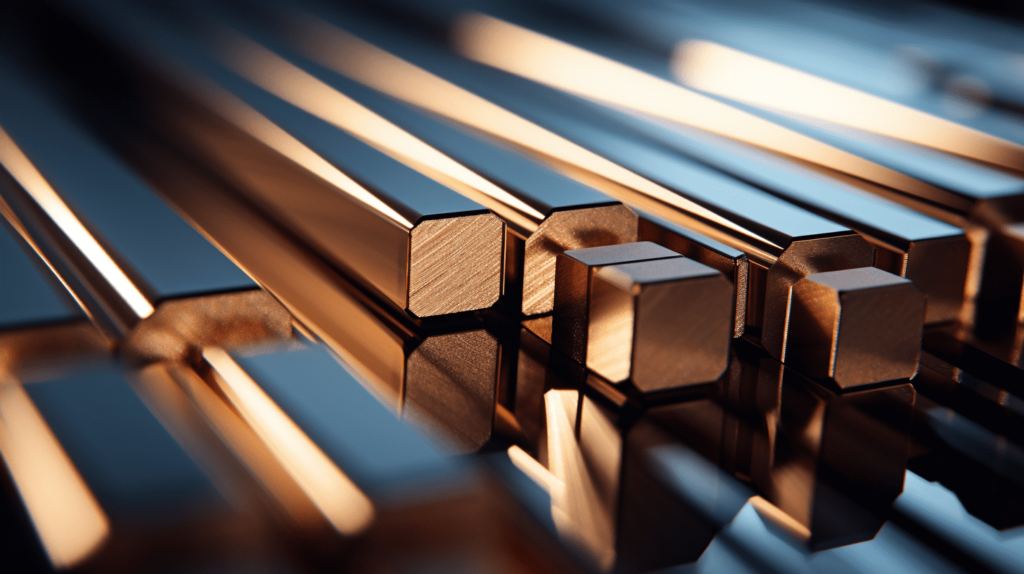

What Are Tungsten Carbide Blanks?

Tungsten carbide blanks are preformed, unsharpened tools made from tungsten carbide, a composite material consisting of tungsten and carbon atoms. This combination results in an extremely hard and dense material capable of withstanding high temperatures and pressures. These blanks serve as the raw material for various cutting, drilling, and wear-resistant tools.

How Do Tungsten Carbide Blanks Work?

Tungsten carbide operates through its unique material properties. The tungsten provides high hardness and a high melting point, while the carbon atoms create a strong covalent bond that enhances durability. The material undergoes a sintering process, where powdered tungsten carbide is pressed and heated to form solid blanks. This process ensures uniform density and hardness throughout the blank.

How to Use Tungsten Carbide Blanks

Using tungsten carbide blanks involves machining or shaping them into the desired tool form. This can include grinding, cutting, and polishing. Specialized equipment, such as diamond-coated tools, is often required due to the material’s hardness. The finished products are then used in various applications, such as manufacturing cutting tools, industrial machinery parts, and wear-resistant components.

How to Process Tungsten Carbide Blanks

Processing tungsten carbide blanks involves several steps:

- Cutting: Using diamond or carbide tools to cut the blanks to the desired size.

- Grinding: Precision grinding to achieve the required shape and surface finish.

- Polishing: Smoothing the surface to enhance performance and longevity.

- Coating: Applying coatings, such as titanium nitride, to improve wear resistance and reduce friction.

Market Trends

The market for tungsten carbide blanks is growing due to the increasing demand for durable and reliable tools in various industries. Key factors driving this growth include:

- Advancements in Manufacturing: Improved manufacturing techniques and technologies enhance the quality and performance of tungsten carbide blanks.

- Demand in Emerging Markets: Rapid industrialization in regions such as Asia-Pacific boosts the demand for high-quality tools and components.

- Sustainability Trends: The recyclability of tungsten carbide makes it an attractive option for eco-conscious industries.

Product Specifications

To help you understand the various options available, here is a detailed table outlining the specifications and characteristics of our high-quality tungsten carbide blanks.

| Type | Composition | Attributes | Features | Specifications | Size Range | Grade | Standard |

|---|---|---|---|---|---|---|---|

| Standard Blanks | WC + Co | High hardness, wear-resistant | Uniform density | ISO certified | 10mm – 100mm | K10, K20, K30 | ISO 9001 |

| Micro-grain Blanks | WC + Co + Additives | Ultra-fine grain, high toughness | Enhanced surface finish | Customizable | 5mm – 50mm | K05, K15 | ASTM B777 |

| Wear Parts Blanks | WC + Ni | Corrosion-resistant, durable | High impact resistance | Industry-specific | 20mm – 200mm | W10, W20 | DIN 9001 |

| Cutting Tool Blanks | WC + Co + TiC | Superior cutting edge retention | High precision machining | OEM available | 2mm – 80mm | K40, K50 | ANSI B212 |

Applications

Tungsten carbide blanks are indispensable in numerous industries. Here are some of the primary applications:

- Metalworking: Cutting tools, drills, and end mills.

- Mining: Wear-resistant parts for drilling and excavation equipment.

- Woodworking: Router bits, saw blades, and planing knives.

- Aerospace: Precision components subjected to high stress and wear.

- Automotive: Engine parts, valve seats, and fuel injector components.

- Oil and Gas: Drill bits, wear-resistant seals, and flow control components.

- Medical: Surgical instruments and dental tools.

- Construction: Concrete cutting and drilling tools.

Comparative Analysis of Suppliers

To aid in your decision-making, the following table compares various suppliers of tungsten carbide blanks based on key criteria.

| Supplier | Location | Price Range (per piece) | Specialties |

|---|---|---|---|

| Kennametal | USA | $20 – $100 | Custom sizes, quick delivery |

| Sandvik | Sweden | $25 – $120 | High precision, ISO certified |

| ZCC Cutting Tools | China | $15 – $90 | Low cost, bulk orders |

| Sumitomo Electric | Japan | $22 – $110 | Advanced coatings, micro-grain |

Advantages and Disadvantages

Here is a comprehensive comparison of the pros and cons of using tungsten carbide blanks.

| Advantages | Disadvantages |

|---|---|

| Exceptional hardness | High cost |

| Wear and corrosion resistance | Difficult to machine without specialized equipment |

| High temperature tolerance | Can be brittle under high impact |

| Long lifespan | Requires precise manufacturing techniques |

| Recyclable material | Can be more expensive than other materials |

| Consistent performance in demanding applications | Limited flexibility in certain applications |

Why Choose TRUER

Choosing TRUER as your high-quality tungsten carbide blanks supplier ensures you receive the finest products backed by exceptional customer service. Our commitment to excellence is reflected in our rigorous quality control processes, competitive pricing, and ability to customize products to meet your specific needs. With TRUER, you benefit from:

- High-Quality Materials: We use only the finest raw materials to ensure superior performance and durability.

- Advanced Manufacturing: Our state-of-the-art facilities and technologies guarantee precision and consistency.

- Extensive Experience: Years of expertise in the industry allow us to provide valuable insights and solutions.

- Customer Support: Our dedicated team is always available to assist with any inquiries or technical support.

FAQ

Here are some frequently asked questions to address common concerns and provide further information about our tungsten carbide blanks.

Q1: What is the lead time for orders?

A1: The lead time varies depending on the order size and customization requirements. Typically, standard orders are processed within 2-4 weeks, while custom orders may take longer.

Q2: Can I request custom sizes and shapes?

A2: Yes, we offer customization services to meet your specific needs. Contact our sales team with your requirements, and we will provide a tailored solution.

Q3: How do I ensure the quality of the blanks?

A3: Our tungsten carbide blanks undergo stringent quality control checks at every stage of production. We also provide material certifications and test reports upon request.

Q4: What payment methods do you accept?

A4: We accept various payment methods, including bank transfers, credit cards, and PayPal. Please contact our billing department for more details.

Q5: Do you offer technical support for machining tungsten carbide blanks?

A5: Yes, our technical team is available to provide guidance and support for machining and processing our tungsten carbide blanks. We can offer recommendations on tools, techniques, and best practices to ensure optimal results.