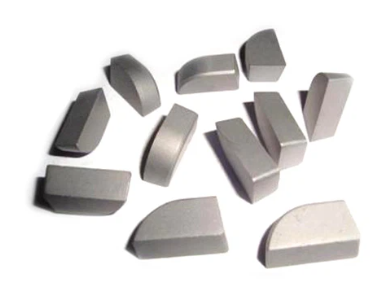

Introduction: Sharper, Stronger, Longer-Lasting Tungsten Carbide Brazed Tips

In the realm of machining and material removal, achieving exceptional precision, efficiency, and tool life hinges on the cutting edge. High-performance tungsten carbide brazed tips have emerged as a game-changer, empowering industries worldwide to push the boundaries of what’s possible. This comprehensive guide delves into the intricacies of these remarkable components, exploring their composition, manufacturing process, diverse applications, and the factors driving their growing adoption.

What are High-Performance Tungsten Carbide Brazed Tips?

A Fusion of Strength and Precision: Where Tungsten Carbide Meets Brazing Technology

High-performance tungsten carbide brazed tips represent a pinnacle of material science and manufacturing ingenuity. They consist of two primary components:

- Tungsten Carbide Insert: The heart of the tip, meticulously engineered from tungsten carbide powder blended with a metallic binder (typically cobalt). This insert possesses exceptional hardness, wear resistance, and hot hardness, making it ideal for demanding cutting applications.

- Steel Shank: Provides a robust and cost-effective base for the carbide insert. The shank is typically made from high-quality alloy steel, offering a balance of strength, toughness, and machinability.

These components are permanently joined through a high-temperature brazing process, creating an inseparable bond that can withstand the extreme forces and temperatures encountered during machining.

The Anatomy of Performance: Key Properties of Tungsten Carbide Brazed Tips

Table 1: Unveiling the Power Within – Properties of High-Performance Tungsten Carbide Brazed Tips

| Property | Description | Benefits in Cutting Applications |

|---|---|---|

| High Hardness | Measures resistance to indentation and deformation. Tungsten carbide ranks among the hardest materials known, exceeding even hardened steel. | Enables tips to maintain sharpness and cutting edge integrity even when machining tough materials at high speeds. |

| Exceptional Wear Resistance | Resists material loss due to abrasion, adhesion, and diffusion wear. | Significantly extends tool life, reducing downtime for tool changes and lowering overall machining costs. |

| High Hot Hardness | Retains hardness and strength at elevated temperatures, resisting softening and deformation. | Crucial for high-speed machining operations where frictional heat can reach extreme levels. |

| Good Fracture Resistance | Withstands impact loads and interrupted cutting conditions without chipping or breaking. | Ensures reliable performance and consistent results, even in challenging machining environments. |

| Chemical Inertness | Resists chemical reactions and corrosion from coolants, lubricants, and workpiece materials. | Extends tool life and prevents workpiece contamination, maintaining cutting efficiency and surface finish. |

Applications Across Industries: Where Precision Meets Versatility

High-performance tungsten carbide brazed tips find applications in a wide range of industries, including:

- Metalworking and Machining: Turning, milling, drilling, and boring operations on various metals, including steel, stainless steel, cast iron, and aerospace alloys.

- Woodworking: Cutting, shaping, and profiling wood and wood-based composites, particularly in high-volume production environments.

- Automotive: Machining engine components, transmission parts, and other critical automotive components requiring high precision and durability.

- Aerospace: Manufacturing aircraft components, turbine blades, and other aerospace parts demanding exceptional material properties and tight tolerances.

- Construction and Mining: Drilling, cutting, and excavating rock, concrete, and other hard materials in construction and mining operations.

Navigating the Market: Comparing Leading Suppliers

Table 2: A Global Perspective – Leading Suppliers of High-Performance Tungsten Carbide Brazed Tips

| Supplier | Location | Price Range (USD/Tip – Approximate) | Specialties |

|---|---|---|---|

| Sandvik Coromant | Sweden | $5 – $50+ | Wide range of grades and geometries, advanced coatings, technical expertise |

| TRUER | China | $4 – $40+ | High-performance Tungsten Carbide Brazed Tips custom tooling solutions, application support |

| Iscar | Israel | $6 – $60+ | Innovative geometries, specialized coatings, focus on productivity enhancement |

| Seco Tools | Sweden | $7 – $70+ | Comprehensive product range, digital machining solutions, sustainability focus |

| Mitsubishi Materials | Japan | $8 – $80+ | High-quality carbide substrates, advanced coatings, precision manufacturing |

Note: Prices are approximate and vary significantly based on tip size, grade, geometry, coating, quantity, and market conditions.

Advantages and Limitations: A Balanced View of Performance

Table 3: Weighing the Pros and Cons – Advantages and Limitations of Tungsten Carbide Brazed Tips

| Advantages | Limitations |

|---|---|

| Exceptional Tool Life: Significantly outlasts conventional steel tools, reducing downtime for tool changes and lowering operating costs. | Higher Initial Cost: Tungsten carbide brazed tips typically command a higher upfront cost compared to steel tools. |

| Increased Cutting Speeds and Feeds: Enables faster machining rates, boosting productivity and reducing cycle times. | Brittle Nature: Susceptible to chipping or breakage under extreme impact loads or improper machining parameters. |

| Improved Surface Finish: Produces smoother, more precise cuts, reducing the need for secondary finishing operations. | Requires Specialized Grinding: Sharpening and reconditioning require specialized grinding wheels and techniques. |

| Enhanced Dimensional Accuracy: Maintains tight tolerances and dimensional stability, even at elevated temperatures. | Limited Application in Certain Materials: Not ideal for machining very soft or gummy materials that can cause edge buildup. |

Beyond the Tip: Factors Influencing Performance and Tool Life

Maximizing the performance and longevity of high-performance tungsten carbide brazed tips involves considering several crucial factors:

- Grade Selection: Choosing the appropriate carbide grade based on the workpiece material, cutting conditions, and desired tool life.

- Geometry Optimization: Selecting the optimal tip geometry (e.g., rake angle, clearance angle, chipbreaker design) to control chip formation, heat generation, and cutting forces.

- Coating Technology: Applying specialized coatings (e.g., TiN, TiAlN, CVD diamond) to enhance wear resistance, reduce friction, and improve tool life in specific applications.

- Machining Parameters: Optimizing cutting speed, feed rate, and depth of cut to balance productivity with tool life and surface finish requirements.

- Coolant Selection and Application: Using appropriate coolants and lubrication strategies to control heat, reduce friction, and improve chip evacuation.

FAQs: Addressing Your Tungsten Carbide Brazed Tip Queries

1. How do I choose the right tungsten carbide grade for my application?

Grade selection depends on factors like workpiece material hardness, cutting speed, feed rate, and desired tool life. Consulting supplier catalogs, machining data, or seeking expert advice is recommended.

2. What are the benefits of using coated tungsten carbide brazed tips?

Coatings enhance wear resistance, reduce friction, improve chip flow, and increase tool life, especially in demanding applications involving high temperatures or abrasive materials.

3. How do I prevent chipping or breakage of tungsten carbide brazed tips?

Using appropriate machining parameters, ensuring proper tool holding and workholding, and avoiding sudden impacts or interruptions during cutting can help prevent tip damage.

4. Can tungsten carbide brazed tips be sharpened and reconditioned?

Yes, they can be sharpened multiple times using specialized grinding wheels and techniques. However, it’s crucial to maintain the original tip geometry and avoid overheating during grinding.

5. What are the latest advancements in tungsten carbide brazed tip technology?

Advancements include the development of new carbide grades with improved toughness and wear resistance, innovative coatings with enhanced performance characteristics, and optimized tip geometries for specific applications.