The carbide market is a fascinating and essential segment of the materials industry. From industrial tools to cutting-edge technologies, carbide plays a pivotal role in modern engineering.

Understanding the Carbide Market

Carbides are compounds composed of carbon and a less electronegative element, often a metal. These materials are renowned for their exceptional hardness, wear resistance, and thermal stability, making them indispensable in various industries. They’re commonly used in the manufacturing of tools, dies, and wear-resistant materials.

In the global market, carbide products include tungsten carbide, silicon carbide, boron carbide, and others. These compounds serve industries like aerospace, automotive, electronics, and even renewable energy. The carbide market has seen steady growth, driven by advancements in technology and increasing demand for high-performance materials.

The Current Status of Global Carbide Market Trends

The global carbide market is experiencing significant transformation. As industries innovate and demand for precision tools rises, the role of carbide continues to expand. Here’s a snapshot of what’s happening:

- Rising Demand in Manufacturing: Carbide’s exceptional properties make it a go-to material for cutting tools and machinery. With the surge in manufacturing activities worldwide, this demand is only expected to increase.

- Shift Toward Sustainability: Eco-friendly manufacturing processes are reshaping the market. Companies are focusing on reducing the carbon footprint of carbide production, using recycled materials and more efficient processes.

- Technological Advancements: Innovations such as nano-carbides and advanced coating technologies are opening new avenues for carbide applications.

- Competition and Pricing: With increasing competition from alternative materials and fluctuations in raw material prices, market dynamics remain challenging.

Key Trends Shaping the Carbide Market

| Trend | Description |

|---|---|

| Additive Manufacturing | Carbides are being integrated into 3D printing for producing high-strength, wear-resistant components. |

| Nano-carbides | The development of nano-sized carbide particles is enhancing material properties like toughness and hardness. |

| Recycling Initiatives | Recycling tungsten and other carbide materials is becoming a significant trend to ensure sustainability. |

| Demand for Wear Resistance | Industries are increasingly relying on carbides for applications requiring durability under extreme conditions. |

| Emerging Markets | Growth in Asia-Pacific, particularly in China and India, is driving the global market. |

| Lightweight Applications | Carbide’s strength-to-weight ratio makes it appealing for aerospace and automotive sectors. |

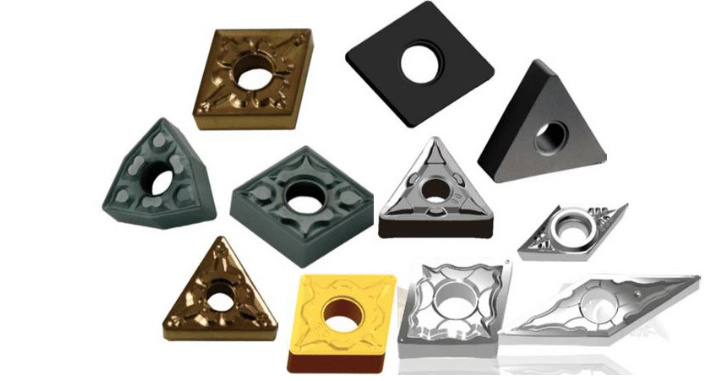

| Advanced Coatings | Coatings like PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) are improving carbide utility. |

| Smart Manufacturing | Industry 4.0 technologies are enabling more efficient carbide production and application. |

| Customized Solutions | Increasing demand for tailored carbide components designed for specific applications. |

| Hybrid Materials | Combining carbide with other materials, like ceramics or polymers, to create composites with unique properties. |

Regional Analysis of Global Carbide Market Trends

The global carbide market varies significantly across regions due to differences in industrial focus, raw material availability, and technological advancement. Let’s take a closer look:

North America

North America remains a strong player, with robust demand in aerospace and defense. The region also benefits from advanced manufacturing capabilities and investments in R&D. The United States leads the charge with significant consumption of tungsten carbide and silicon carbide.

Europe

Europe’s carbide market is driven by its automotive sector. Germany, known for its engineering prowess, is a key consumer. Sustainability initiatives are influencing carbide production, with a focus on reducing emissions and recycling.

Asia-Pacific

The Asia-Pacific region is the largest and fastest-growing market. Countries like China and India dominate due to their burgeoning manufacturing industries. China, in particular, is a major producer and consumer, contributing to the global supply chain.

Latin America and Middle East

These regions show moderate growth. Latin America’s mining activities drive carbide demand, while the Middle East’s oil and gas sector sees applications in wear-resistant materials.

The Future of Carbide Plates for Dies

Carbide plates for dies are crucial in industries like metal stamping and extrusion. What does the future hold?

- Enhanced Durability: Advanced manufacturing processes and material treatments will make carbide plates even more durable and wear-resistant.

- Customization: As industries demand more tailored solutions, manufacturers will produce plates with specific hardness, thickness, and geometries.

- Eco-friendly Solutions: The industry is likely to shift towards greener production methods, incorporating recycled materials and energy-efficient technologies.

- Integration with Smart Systems: The rise of smart manufacturing will see carbide plates integrated into automated systems for enhanced productivity.

Applications of Carbides in Tool Manufacturing, Cutting Tools, and Wear-resistant Materials

| Application | Description |

|---|---|

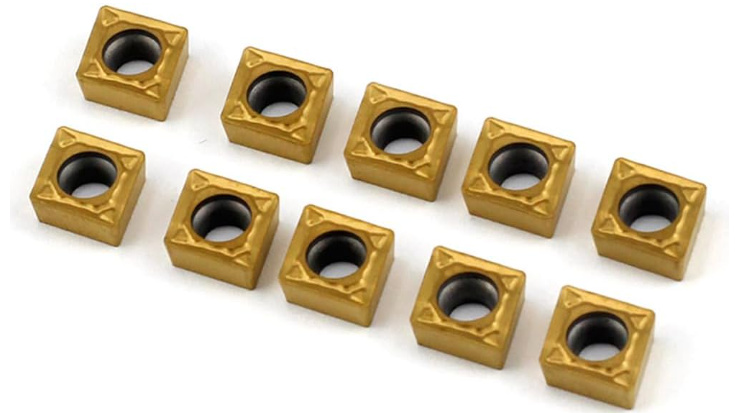

| Tool Manufacturing | Carbides are used to produce high-precision tools like drills, end mills, and lathe inserts. |

| Cutting Tools | Carbide-tipped tools provide exceptional cutting performance in metalworking, woodworking, and more. |

| Wear-resistant Materials | Industries use carbide coatings and components to withstand extreme wear in mining, oil and gas, and chemicals. |

| Construction Equipment | Carbides are used in the production of durable equipment like excavator teeth and crusher components. |

| Electronics | Silicon carbide is widely used in semiconductors for its excellent thermal and electrical properties. |

| Aerospace and Defense | Carbides find applications in creating lightweight yet durable components for high-stress environments. |

| Automotive | Carbides are essential in engine parts, transmission systems, and wear-resistant components. |

| Energy Sector | From wind turbines to nuclear reactors, carbide plays a role in ensuring durability and performance. |

| Medical Devices | Precision carbide tools are used in surgical instruments and implants. |

| Renewable Energy Technologies | Silicon carbide enables efficient energy conversion in solar inverters and electric vehicles. |

The Application of Carbide Market in Emerging Application Fields

The future of the carbide market lies in exploring emerging fields. Here are some key areas:

- Renewable Energy: Carbides like silicon carbide are transforming solar and wind energy systems by improving efficiency.

- 5G Technology: The high thermal conductivity of silicon carbide makes it ideal for 5G base stations and communication systems.

- Advanced Electronics: From electric vehicles to smart grids, carbide materials support next-generation electronic applications.

- Medical Technologies: Carbides are increasingly used in biomedical implants and surgical tools due to their biocompatibility.

- Space Exploration: Lightweight carbides are critical for spacecraft and satellite components.

Market Drivers and Challenges of Global Carbide Market Trends

| Driver/Challenge | Description |

|---|---|

| Driver: Industrial Growth | Increased manufacturing activities globally are boosting carbide demand. |

| Driver: Technological Innovation | Innovations like nano-carbides and advanced coatings are expanding market potential. |

| Driver: Sustainability Focus | Eco-friendly production and recycling initiatives are driving industry growth. |

| Challenge: Raw Material Availability | Dependence on rare elements like tungsten poses supply chain challenges. |

| Challenge: High Production Costs | The cost-intensive nature of carbide manufacturing can deter smaller players. |

| Challenge: Competition | Alternatives like ceramics and high-speed steels present stiff competition. |

| Challenge: Regulatory Pressure | Environmental regulations could increase operational costs for manufacturers. |

FAQs

| Question | Answer |

|---|---|

| What are the primary types of carbide? | Tungsten carbide, silicon carbide, boron carbide, and titanium carbide are some of the primary types. |

| Which industries use carbide the most? | Aerospace, automotive, construction, electronics, and energy are major consumers. |

| Why is carbide preferred in cutting tools? | Carbide’s hardness, thermal stability, and wear resistance make it ideal for cutting applications. |

| How is the carbide market adapting to sustainability? | Recycling initiatives and eco-friendly production methods are reshaping the industry. |

| What regions lead in carbide production? | Asia-Pacific, especially China and India, dominates global carbide production. |

| What’s the future of carbide materials? | Emerging applications in electronics, renewable energy, and medical technologies hold promise. |

| Are there alternatives to carbide? | Yes, materials like ceramics and high-speed steel compete with carbide in certain applications. |