Introduction: Unleashing the Power of Tungsten Carbide

In the realm of industrial manufacturing and machining, precision, durability, and efficiency are paramount. Enter cemented carbide blanks, the unsung heroes behind countless cutting-edge tools and wear-resistant components. These engineered materials, primarily composed of tungsten carbide particles bonded by a metallic binder, offer exceptional hardness, wear resistance, and hot hardness, making them ideal for demanding applications.

This comprehensive guide delves into the world of custom-made cemented carbide blanks, exploring their properties, manufacturing processes, applications, and the advantages of partnering with a specialized manufacturer.

What are Custom-Made Cemented Carbide Blanks?

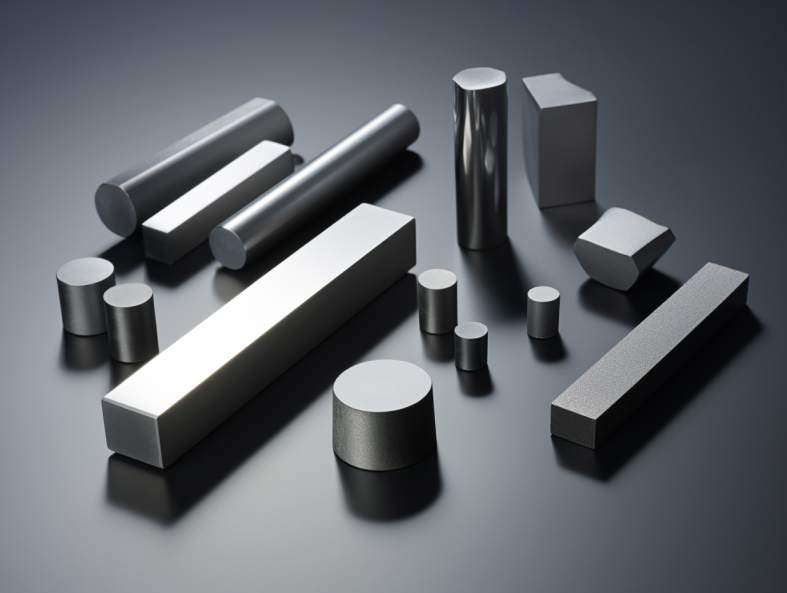

Cemented carbide blanks are pre-sintered or fully sintered forms of tungsten carbide-based materials, typically cylindrical or rectangular in shape, that serve as the foundation for various cutting tools, wear parts, and other components. “Custom-made” signifies that these blanks are tailored to specific dimensions, geometries, grades, and properties based on the customer’s unique application requirements.

Understanding the Manufacturing Process

The production of custom-made cemented carbide blanks involves a meticulous multi-step process:

- Powder Preparation: Tungsten carbide (WC) powder and a binder metal powder, usually cobalt (Co), are precisely mixed in desired proportions to achieve specific material properties.

- Pressing: The powder mixture is pressed into the desired blank shape using high-pressure dies.

- Presintering: The pressed blanks undergo a controlled heating process to impart green strength and prepare them for final sintering.

- Sintering: The presintered blanks are subjected to high temperatures in a controlled atmosphere furnace. This process fuses the WC particles through liquid-phase sintering, resulting in a dense, hard material.

- Finishing: After sintering, the blanks may undergo various finishing operations such as grinding, lapping, or polishing to achieve precise dimensions and surface finishes.

The Versatility of Custom-Made Carbide Blanks

Custom-made cemented carbide blanks offer unparalleled versatility, allowing manufacturers to optimize tool performance for specific machining operations and material types. By tailoring the WC grain size, cobalt content, and other alloying additions, manufacturers can fine-tune the blank’s hardness, toughness, and wear resistance.

Navigating the World of Carbide Grades

Cemented carbide blanks are categorized into different grades based on their composition and properties. Selecting the appropriate grade is crucial for optimal tool performance and longevity.

Table 1: Common Cemented Carbide Grades and Their Characteristics

| Grade | WC Content (%) | Co Content (%) | Typical Applications | Key Properties |

|---|---|---|---|---|

| K01 | 94 | 6 | Finishing of steel, cast iron, and non-ferrous metals | High hardness, excellent wear resistance |

| K10 | 90 | 10 | General-purpose machining of steel, cast iron, and non-ferrous metals | Good balance of hardness and toughness |

| K20 | 85 | 15 | Roughing and interrupted cutting of steel and cast iron | High toughness, good wear resistance |

| M10 | 88 | 12 | Machining of stainless steel, high-temperature alloys, and titanium alloys | High hot hardness, good wear resistance |

Applications Across Industries

The exceptional properties of custom-made cemented carbide blanks have led to their widespread adoption across numerous industries:

- Metalworking and Machining: This sector represents a primary consumer of carbide blanks, utilizing them for a vast array of cutting tools. Drills, end mills, inserts for turning and milling, and saw tips all benefit from the hardness and wear resistance of carbide, enabling them to machine various metals with precision and longevity.

- Woodworking: The woodworking industry relies on carbide’s ability to maintain a sharp edge for extended periods. Carbide-tipped saw blades produce cleaner cuts with less effort, while router bits and planer knives equipped with carbide inserts excel in shaping and smoothing wood.

- Construction and Mining: The unforgiving environments of construction and mining demand tools with exceptional durability. Carbide drill bits effortlessly bore through concrete, rock, and other tough materials, while specialized rock drilling tools equipped with carbide inserts maximize drilling efficiency and minimize downtime. Wear parts made from carbide protect critical components in heavy machinery from abrasion and impact.

- Oil and Gas: The extraction and processing of oil and gas present extreme conditions where carbide thrives. Downhole drilling tools tipped with carbide withstand the abrasive forces encountered deep underground, while wear rings and valve components fabricated from carbide ensure the longevity and reliability of critical equipment.

- Aerospace: The aerospace industry demands lightweight yet incredibly strong materials capable of withstanding high temperatures and demanding conditions. Carbide plays a crucial role in this sector, finding application in turbine blades for jet engines, wear-resistant components in landing gear, and even structural parts requiring exceptional strength-to-weight ratios.

Comparing Carbide Blank Suppliers

Selecting the right cemented carbide blank supplier is crucial for ensuring product quality, timely delivery, and competitive pricing.

Table 2: Comparison of Cemented Carbide Blank Suppliers

| Supplier | Location | Price Range (per piece, USD) | Specialties |

|---|---|---|---|

| Kennametal | USA | $10 – $500+ | Wide range of grades, complex geometries, coatings |

| Sandvik Coromant | Sweden | $15 – $600+ | Advanced grades, precision grinding, technical support |

| CERATIZIT | Luxembourg | $8 – $400+ | Cost-effective solutions, standard and custom grades |

| ISCAR | Israel | $12 – $550+ | Innovative geometries, specialized coatings, technical expertise |

| Mitsubishi Materials | Japan | $14 – $650+ | High-performance grades, tight tolerances, reliable supply |

| TRUER | China | $8 – $450+ | High-quality, cost-effective carbide blanks; Expertise in geological mining products; Vertically integrated manufacturing with advanced pressing technology for superior precision and stability |

Note: Prices are approximate and can vary significantly based on blank size, grade, quantity, and other factors.

Advantages and Limitations of Custom-Made Carbide Blanks

Table 3: Advantages and Limitations of Custom-Made Cemented Carbide Blanks

| Advantages | Limitations |

|---|---|

| Enhanced Performance: Tailored properties for specific applications | Higher Initial Cost: Compared to standard blanks |

| Increased Tool Life: Superior wear resistance reduces downtime and tooling costs | Longer Lead Times: Custom manufacturing requires additional time |

| Improved Productivity: Higher cutting speeds and feeds increase output | Design Complexity: Intricate geometries may pose manufacturing challenges |

| Reduced Scrap Rates: Precise dimensions and consistent quality minimize waste |

Why Choose Custom-Made Cemented Carbide Blanks?

- Uncompromising Performance: Achieve optimal tool performance and efficiency for your specific machining challenges.

- Cost Savings Over Time: Extended tool life and reduced downtime translate into significant cost savings.

- Enhanced Product Quality: Precise dimensions and consistent material properties ensure high-quality finished products.

- Competitive Advantage: Leverage cutting-edge tooling solutions to stay ahead in today’s demanding market.

Frequently Asked Questions FAQ of Cemented Carbide Blanks

1. What is the typical lead time for custom-made carbide blanks?

Lead times vary depending on the complexity of the design, grade selection, and the supplier’s production capacity. Typically, lead times range from 4 to 8 weeks.

2. Can cemented carbide blanks be coated?

Yes, various coatings, such as titanium nitride (TiN), titanium aluminum nitride (TiAlN), and diamond-like carbon (DLC), can be applied to enhance wear resistance, reduce friction, and improve tool life.

3. What is the difference between presintered and fully sintered blanks?

Presintered blanks are partially sintered and require further processing to achieve final dimensions and properties. Fully sintered blanks are ready for grinding and finishing operations.

4. How do I choose the right carbide grade for my application?

Selecting the appropriate grade depends on factors such as the material being machined, cutting speed and feed rates, and required tool life. Consulting with a carbide expert or referring to supplier catalogs can aid in grade selection.

5. What are the key considerations for designing custom carbide blanks?

Key considerations include the desired tool geometry, cutting edge preparation, chip evacuation, and the material’s mechanical and thermal properties. Close collaboration between the customer and the carbide blank manufacturer is essential for successful design and implementation.