Chinese Carbide Blanks refer to unfinished carbide rods and plates used for manufacturing cutting tools and dies. China has grown into a major supplier of quality carbide blanks catering to global demand. This guide provides a detailed overview of Chinese carbide blanks.

Introduction to Chinese Carbide Blanks

Carbide blanks are semi-finished carbide stock supplied for final grinding and machining into cutting tools. Key properties:

- Extreme hardness for wear resistance

- Strength at high temperatures

- Resistance to abrasion and corrosion

- Dimensional stability in operation

- Raw material for inserts, drills, end mills, etc.

Carbide blank types:

- Tungsten carbide blanks – WC primary constituent

- Titanium carbide blanks – High hot hardness

- Tantalum carbide blanks – Most wear resistant

- Cermet blanks – Carbide particles in metal matrix

Accurately machined blanks enable consistent tooling quality and performance.

Manufacturing Process for Carbide Blanks

Carbide Blank Manufacturing Steps:

- Weighing and mixing of carbide, binder, and dopant powders

- Compacting into green blanks via pressing or extrusion

- Debinding to remove binders at 500-600°C

- Vacuum sintering at 1300-1500°C to form dense carbide

- Annealing to release internal stresses

- Grinding to tight diameters and finishes

- Brazing of carbide rods for multilayer blanks

- Final quality control as per ISO standards

Automation allows high volume blank production with minimal variability between batches.

Types of Chinese Carbide Blanks

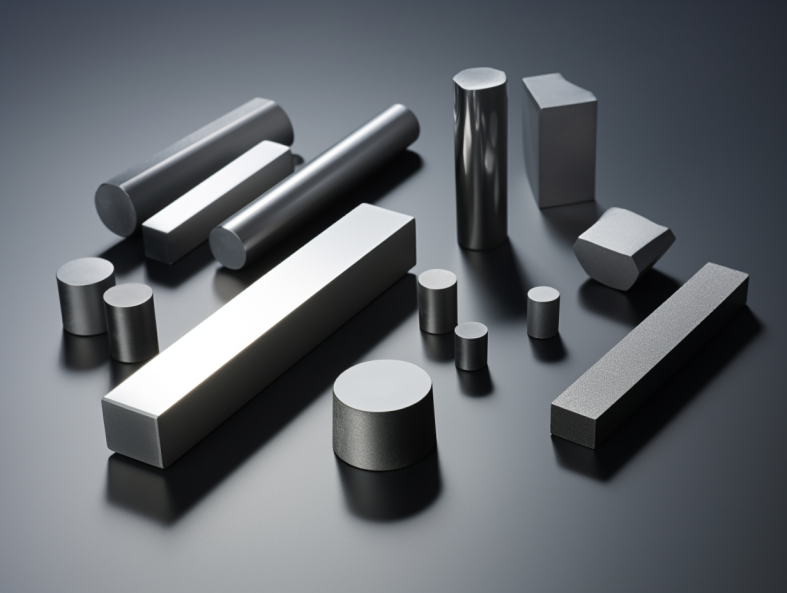

China produces all standard blank configurations from tungsten carbide, titanium carbide, tantalum carbide, and cermets:

Types of Chinese Carbide Blanks

| Type | Description |

|---|---|

| Round rod | Cylindrical blank for drills, end mills |

| Square rod | For milling tool inserts, forming tools |

| Rectangular bar | Blanks for parting tools and custom shapes |

| Flat plate | For inserts, punching/embossing dies |

| Grooving insert | Preforms for turning, threading, grooving |

| Mining pick | Blanks for mining and construction picks |

Both solid and brazed carbide blanks are available. Advanced geometries and custom configurations can also be produced as per specifications.

Composition of Carbide Blanks

Typical Compositions:

- WC-Co – tungsten carbide with cobalt binder

- TiC-NiMo – titanium carbide with nickel-molybdenum binder

- TaC-WC-Co – tantalum-tungsten carbide cobalt

- WC-TiC-TaC-Co – mixed carbides with cobalt

- TiCN-Ni – Titanium carbonitride-nickel cermet

Binder metals like cobalt, nickel, and molybdenum facilitate sintering. Details composition depends on application requirements.

Properties of Carbide Blanks

Properties of Carbide Blanks

| Property | Typical Values |

|---|---|

| Hardness | 88-94 HRA |

| Transverse rupture strength | 500-3500 MPa |

| Density | 12-15 g/cm3 |

| Maximum service temperature | 600-1000°C |

| Young’s modulus | 550-650 GPa |

| Fracture toughness | 10-12 MPa√m |

| Thermal conductivity | 60-100 W/mK |

The combination of extreme hardness, strength, and high temperature resistance enables reliable performance in tooling applications.

Dimensions and Sizes of Carbide Blanks

China supplies standard and custom carbide blank sizes:

Standard Carbide Blank Sizes

| Type | Diameter Range |

|---|---|

| Round rods | 0.5mm – 65mm |

| Square rods | 2mm – 32mm |

| Rectangular bars | 2x4mm – 25x32mm |

| Flat plates | Thickness: 2 – 15mm |

Custom Dimensions

China factories offer complete flexibility in carbide geometries and dimensions as per application requirements. Complex carbide assemblies can also be manufactured.

Grades of Carbide Blanks

Carbide grades have specific compositions tailored to end use:

Carbide Blank Grades

| Grade | Description | Application |

|---|---|---|

| K10 | Fine grained tungsten carbide | Low wear tools |

| K20 | Cobalt-enriched WC | Toughness for mining |

| C6-C7 | 6% cobalt binder | General machining inserts |

| K40 | High cobalt, very tough | Mining, recycling |

| H10, H13 | High hardness TiC based | High speed steel tools |

Manufacturers select optimum carbide compositions based on operating conditions the tooling will be subjected to during service life.

Quality Standards for Chinese Carbide Blanks

Chinese factories supply carbide blanks conforming to international standards:

- ISO 1832 – Structure, designation, and coding of hardmetals

- ASTM B776 – Standard for sintered tungsten carbide plates

- JIS R 1601 – Classification and coding of hardmetals

- GB/T 20846 – Chinese standard for cemented carbides

Compliance with standards ensures product quality and performance. Customers can review test reports to verify specifications are met.

Applications of Carbide Blanks

Applications of Carbide Blanks

| Industry | Application |

|---|---|

| Automotive | Cutting, drilling, milling tools |

| Aerospace | Machining turbine blades, structural parts |

| Energy | Drill bits, wire drawing dies |

| Die and mold | Punching, stamping, embossing dies |

| General engineering | Turning, boring, grooving inserts |

| Construction | Road milling, drilling in rock |

Carbide blanks enable reliable, high-performance metalworking across industries requiring extreme hardness, wear and heat resistance.

Benefits of Sourcing Chinese Carbide Blanks

Benefits of Chinese Carbide Blanks

- High quality at competitive pricing

- Wide range of international grades and custom alloys

- Flexibility in dimensions, geometries, and tolerance

- Shorter lead times and quick turnaround

- One stop shop for various configurations

- Vertically integrated large-scale production

- Process expertise and technical know-how

- Compliance with global quality standards

- Convenient shipping and export logistics

China offers a combination of capabilities, cost-effectiveness, and compliance ideal for carbide blank buyers.

Chinese Carbide Blanks Manufacturers

Major Chinese Carbide Blank Suppliers

| Company | Location |

|---|---|

| Zhuzhou Jinggong Cemented Carbide | Zhuzhou, Hunan |

| Zhuzhou Mingri Cemented Carbide | Zhuzhou, Hunan |

| Zigong Cemented Carbide | Zigong, Sichuan |

| Guiyang Golden Crystal | Guiyang, Guizhou |

| Chengdu Bangpu Cemented Carbide | Chengdu, Sichuan |

| Guangdong Xianglu Tungsten | Jiangmen, Guangdong |

These large producers cater to international buyers looking for price competitive Chinese carbide blanks without compromising on quality or service.

Pricing Analysis of Carbide Blanks

China Carbide Blank Cost Breakdown

| Product | Price per piece |

|---|---|

| Ø10mm x 50mm WC rod | $5 – $8 |

| Ø20mm x 100mm TiC plate | $15 – $25 |

| 5mm x 5mm x 100mm TaC bar | $10 – $15 |

Pricing depends on blank dimensions, tolerances, carbide grade, order quantity, and configuration complexity. Competitive pricing from China saves significant cost over domestic sourcing in most countries.

Pros and Cons of Sourcing Chinese Carbide Blanks

Advantages

- Cost savings of 40-60% vs domestic suppliers

- High consistency and repeatability

- Shorter lead times for popular sizes

- Customization as per exact requirements

- Single source for multiple configurations

- Smooth importing and customs

- Technical expertise in carbide manufacturing

- Compliance with international standards

Challenges

- Minimum order quantity requirements

- Freight costs on smaller orders

- Language barriers during communication

- Need to verify supplier quality and capabilities

- Longer lead time for custom geometries

- Difficulty returning or exchanging defective pieces

Working with the right partner helps buyers overcome downsides and leverage China’s strengths in carbide blanks.

Comparison Between Chinese and Domestic Carbide Blanks

Carbide Blanks – China vs Domestic Supply

| Parameter | China | Domestic |

|---|---|---|

| Cost | Lower by 40-60% | Higher priced |

| Lead time | 4 weeks standard | 2-3 weeks |

| Customization | Excellent, flexible | Limited flexibility |

| Quality | Equal if supplier is qualified | Possibly higher |

| Shipping | By sea – slower | Local – faster |

| Minimum order | Higher MOQs | Lower MOQs |

For balance of cost, quality, and flexibility, China has surpassed local supply in most foreign markets for standard and custom-made carbide blanks.

FAQ

Q: What are the major types of carbide blanks available from China?

A: The main options are tungsten carbide, titanium carbide, tantalum carbide, and TiCN cermet. Both solid and brazed multipiece configurations are available.

Q: What industries purchase carbide blanks from China?

A: Automotive, aerospace, machinery, die and mold, mining, construction, and general engineering are the key industry customers.

Q: Does China supply carbide blanks as per international standards?

A: Yes, Chinese factories comply with ISO, ASTM, JIS, and other global standards for composition, quality, and testing of carbide blanks. Third party certification can also be provided.

Q: How to find a reliable carbide blank supplier in China?

A: Verify industry experience, quality certifications, customer reviews, production capacity, international exports, and technical expertise when evaluating Chinese carbide blank manufacturers.

Q: What quality control is implemented for carbide blanks in China?

A: Stringent process monitoring, raw material controls, final inspection, metallography, mechanical testing, and dimensional calibration ensure consistent and reliable carbide blank quality.