Introduction

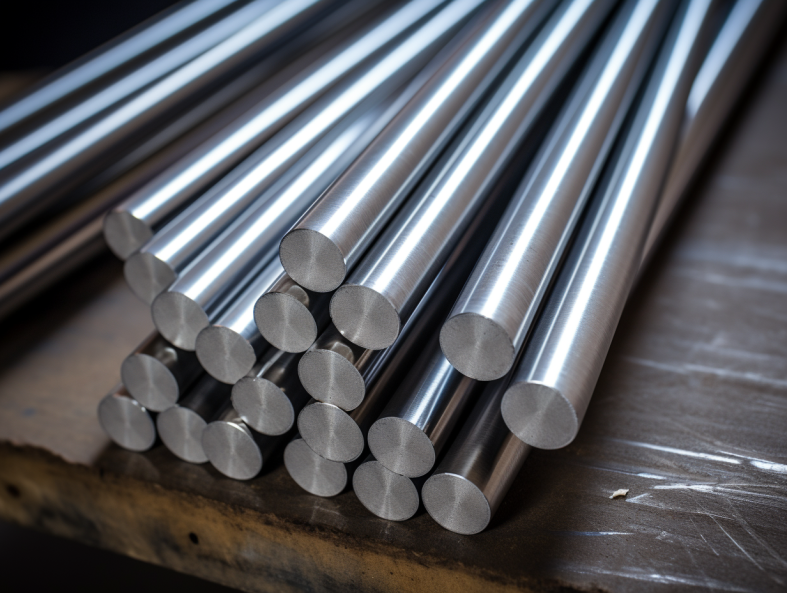

Overview of carbide rods

Carbide rods are widely used in various industries, including manufacturing, construction, and mining. They are known for their exceptional hardness and durability, making them ideal for applications that require cutting, drilling, and shaping hard materials. China is one of the leading producers of carbide rods, with a strong reputation for producing high-quality products. The Chinese carbide rod industry has been growing rapidly in recent years, thanks to advancements in manufacturing technology and increasing demand from domestic and international markets. With its competitive pricing and reliable performance, China’s carbide rods have become a popular choice for businesses around the world.

Importance of carbide rods in various industries

Carbide rods play a crucial role in various industries, and their importance cannot be overlooked. These high-performance tools are widely used in manufacturing processes such as metalworking, woodworking, and mining. The exceptional hardness and durability of carbide rods make them ideal for cutting, drilling, and shaping materials with precision and efficiency. In the automotive industry, carbide rods are used for machining engine components and creating intricate molds. Similarly, in the construction industry, they are indispensable for drilling holes and cutting concrete. The aerospace and defense sectors also rely on carbide rods for their strength and resistance to wear. Overall, carbide rods are essential tools that enhance productivity and quality in a wide range of industries.

Brief history of carbide rod production in China

Carbide rod production in China has a rich and extensive history. Dating back several decades, China has been a leading producer of carbide rods, supplying both domestic and international markets. The country’s expertise in carbide rod production can be attributed to its abundant tungsten reserves and advanced manufacturing capabilities. Over the years, China has continuously invested in research and development to improve the quality and efficiency of carbide rod production processes. As a result, Chinese carbide rod manufacturers have gained a strong reputation for producing high-quality, durable, and reliable products. Today, China remains a major player in the global carbide rod industry, contributing significantly to the growth and advancement of this sector.

Properties of China unground carbide rods

Composition and structure

The composition and structure of China unground carbide rods play a crucial role in their performance and durability. These rods are typically made from a combination of tungsten carbide and cobalt, with varying ratios depending on the desired properties. Tungsten carbide provides the hardness and wear resistance, while cobalt acts as a binder, holding the carbide grains together. The structure of the rods is typically a homogeneous mixture of tungsten carbide grains embedded in a cobalt matrix. This structure ensures the rods have high strength, excellent thermal stability, and resistance to deformation. The precise composition and structure of China unground carbide rods are carefully engineered to meet the specific requirements of various industrial applications, such as cutting, drilling, and machining. Overall, the composition and structure of these rods contribute to their exceptional performance and make them a preferred choice in many industries.

Hardness and wear resistance

China is known for its high-quality carbide rods, specifically in the field of hardness and wear resistance. These carbide rods are manufactured using advanced techniques and technologies, ensuring superior performance in various industrial applications. The hardness of these rods enables them to withstand extreme conditions and heavy loads, making them ideal for use in cutting tools, drilling equipment, and machining operations. Additionally, their exceptional wear resistance ensures a longer lifespan, reducing the need for frequent replacements and increasing productivity. With China’s expertise in producing carbide rods with excellent hardness and wear resistance, it has become a leading supplier in the global market.

Heat resistance and thermal conductivity

China unground carbide rods are known for their exceptional heat resistance and high thermal conductivity. These rods are specifically designed to withstand extreme temperatures and maintain their structural integrity. The heat resistance of these carbide rods makes them suitable for various applications in industries such as aerospace, automotive, and manufacturing. Additionally, the high thermal conductivity ensures efficient heat transfer, making them ideal for heat dissipation in heat sinks and other cooling applications. With their superior heat resistance and thermal conductivity, China unground carbide rods are a reliable choice for demanding thermal management requirements.

Applications of China unground carbide rods

Metalworking industry

The metalworking industry plays a crucial role in the manufacturing sector, and China has emerged as a global leader in this field. One of the key components in metalworking processes is carbide rods, which are widely used for cutting, drilling, and shaping various materials. China’s unground carbide rods have gained significant popularity due to their high quality, durability, and cost-effectiveness. These rods are known for their exceptional hardness and resistance to wear, making them ideal for demanding metalworking applications. With China’s expertise in manufacturing and continuous innovation, the country’s unground carbide rods have become a preferred choice for metalworking professionals worldwide.

Woodworking industry

The woodworking industry plays a significant role in the manufacturing sector in China. With the growing demand for high-quality wood products, the industry has experienced substantial growth in recent years. China’s production of carbide rods has become an essential component of the woodworking industry, providing durable and reliable tools for cutting and shaping wood. These carbide rods are known for their exceptional hardness and resistance to wear, making them ideal for use in woodworking applications. As China continues to invest in its manufacturing capabilities, the woodworking industry is expected to further expand, contributing to the country’s economic development.

Mining and construction industry

The mining and construction industry in China has been experiencing significant growth in recent years. With the country’s rapid urbanization and infrastructure development, there has been a high demand for carbide rods. Carbide rods are widely used in mining and construction applications, providing strength and durability to drilling and cutting tools. China has emerged as a leading producer and exporter of carbide rods, catering to the needs of both domestic and international markets. The industry has witnessed advancements in technology, leading to the production of high-quality carbide rods that meet the stringent requirements of the mining and construction sector. This has further boosted the industry’s growth and contributed to China’s position as a global leader in the mining and construction industry.

Manufacturing process of China unground carbide rods

Raw material selection

When it comes to the production of China unground carbide rods, raw material selection plays a crucial role. The quality and performance of the carbide rods greatly depend on the quality of the raw materials used. China, being one of the leading producers of carbide rods, ensures that only the finest and most suitable raw materials are chosen for the manufacturing process. Careful consideration is given to factors such as chemical composition, purity, and hardness of the raw materials to ensure that the resulting carbide rods meet the highest standards. With a meticulous raw material selection process, China unground carbide rods are known for their exceptional durability, strength, and precision.

Mixing and grinding

Mixing and grinding are essential processes in the production of China unground carbide rods. In the mixing stage, various materials such as tungsten carbide powder, cobalt powder, and other additives are combined to achieve the desired composition. This mixture is then subjected to grinding, where it is finely ground to ensure uniformity and proper particle size distribution. The quality of the mixing and grinding processes directly affects the performance and durability of the carbide rods. Therefore, strict control and precision are crucial to produce high-quality China unground carbide rods.

Sintering and shaping

Sintering and shaping are essential processes in the production of China unground carbide rods. Sintering involves heating the raw materials, typically tungsten carbide and cobalt, to a high temperature in a controlled atmosphere. This process allows the particles to bond together, forming a solid and dense structure. Shaping, on the other hand, involves forming the sintered carbide into the desired shape and dimensions. This can be achieved through various techniques such as grinding, milling, or wire EDM. Both sintering and shaping play a crucial role in determining the quality and performance of China unground carbide rods, ensuring they meet the required specifications for various industrial applications.

Quality control of China unground carbide rods

Testing methods for hardness and wear resistance

In order to determine the hardness and wear resistance of China unground carbide rods, several testing methods are commonly employed. One of the most widely used methods is the Rockwell hardness test, which measures the depth of penetration of an indenter into the material. Another common method is the Vickers hardness test, which uses a diamond indenter to create an impression on the surface of the carbide rod. Additionally, the wear resistance of the rods can be assessed through wear tests, such as the pin-on-disc test or the ball-on-disc test. These tests involve subjecting the carbide rods to sliding or rolling contact with another material under controlled conditions. By using these testing methods, manufacturers and researchers can ensure that China unground carbide rods meet the required hardness and wear resistance specifications.

Inspection of dimensional accuracy

The inspection of dimensional accuracy is a crucial step in ensuring the quality of China unground carbide rods. This process involves measuring the various dimensions of the rods, such as diameter, length, and straightness, to ensure they meet the specified tolerances. Precise measurements are taken using specialized tools and equipment, and any deviations from the required dimensions are carefully noted. This meticulous inspection helps identify any potential issues or defects in the carbide rods, ensuring that only high-quality products are delivered to customers. By conducting thorough dimensional accuracy inspections, manufacturers can guarantee the performance and reliability of China unground carbide rods in various applications.

Evaluation of chemical composition

The evaluation of the chemical composition of China unground carbide rods is crucial in determining their quality and performance. The composition of these rods plays a significant role in their hardness, strength, and wear resistance. Various elements such as tungsten, carbon, cobalt, and other trace elements are carefully balanced to achieve the desired properties. Through rigorous testing and analysis, manufacturers ensure that the chemical composition meets the required standards and specifications. This evaluation process ensures that the carbide rods are suitable for various applications, including cutting, drilling, and milling. By understanding the chemical composition, users can make informed decisions about the suitability of these rods for their specific needs.

Future prospects and challenges

Advancements in carbide rod production technology

In recent years, there have been significant advancements in carbide rod production technology, particularly in China. The production of carbide rods, which are essential components in various industries such as automotive, aerospace, and manufacturing, has undergone significant improvements in terms of quality, durability, and precision. These advancements have been made possible due to the integration of cutting-edge manufacturing techniques, such as computer numerical control (CNC) machining and advanced materials science. The use of advanced technologies has resulted in the production of carbide rods that exhibit enhanced hardness, wear resistance, and dimensional accuracy, meeting the ever-increasing demands of modern industries. With these advancements, China has emerged as a leading producer of high-quality carbide rods, catering to the global market and contributing to the growth of various sectors worldwide.

Increasing demand and market opportunities

The increasing demand for China unground carbide rods has created significant market opportunities. With the growing industrial sectors and the need for high-quality cutting tools, the demand for carbide rods has been on the rise. China, being one of the leading manufacturers of carbide rods, has capitalized on this opportunity and has become a major player in the global market. The high performance and durability of China unground carbide rods have made them a preferred choice for various applications, including metalworking, woodworking, and mining. As the demand continues to grow, there are ample opportunities for businesses to tap into this market and expand their operations.

Environmental and sustainability concerns

Environmental and sustainability concerns are of paramount importance in today’s world, and the production of China unground carbide rods is no exception. With the increasing demand for these rods in various industries, it is crucial to address the potential environmental impacts associated with their manufacturing process. Efforts should be made to minimize the carbon footprint and reduce the use of harmful chemicals during production. Additionally, sustainable sourcing of raw materials and responsible waste management practices should be implemented to ensure the long-term viability of the industry. By prioritizing environmental and sustainability concerns, China can not only meet the needs of its industries but also contribute to a greener and more sustainable future.