Tungsten carbide round blanks from China offer an economical source of this versatile material for machining into cutting tools, dies, bearings and wear parts. This guide provides manufacturers with a detailed overview of China tungsten carbide blanks including properties, grades, quality considerations, uses, cost analysis and leading suppliers.

Introduction to Tungsten Carbide Round Blanks

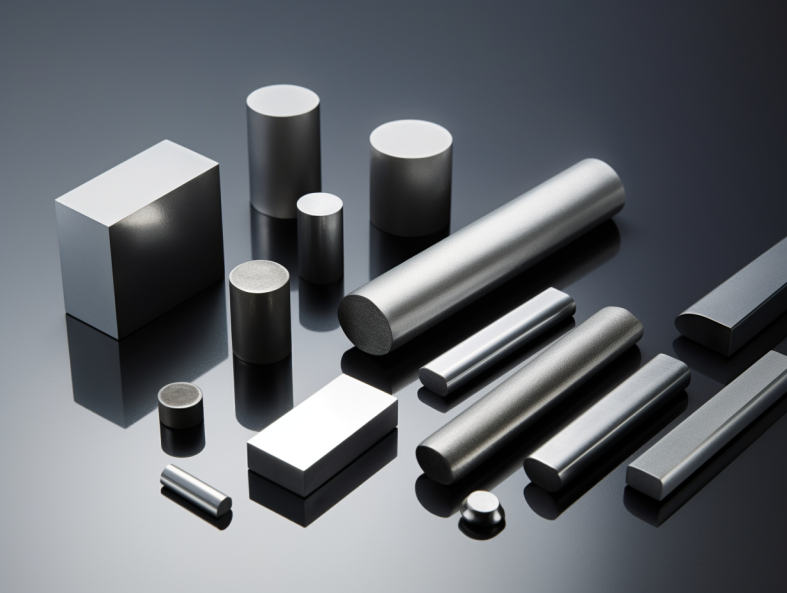

Tungsten carbide round blanks are preforms that can be machined into various components taking advantage of tungsten carbide’s extreme hardness and wear resistance. Key properties include:

- Made from tungsten carbide (WC) bonded with cobalt or nickel

- Much higher hardness than regular tool steel

- Excellent resistance to wear, abrasion, deformation

- Good strength and toughness

- Available in rod blanks, cylinder blanks, flat blanks

- Requires machining/grinding into final shape

- Low cost forming approach compared to sintering end geometry

Tungsten carbide’s unique properties make it an ideal material for cutting tools, pins, dies, bearings, nozzle inserts, and other wear components. Using pre-formed blanks provides a cost-effective method of getting near-net shape parts out of tungsten carbide.

This guide covers China tungsten carbide round blanks in detail including types, grades, quality, machining, uses, costs, and leading suppliers.

Types of Tungsten Carbide Round Blanks

China tungsten carbide blanks are available in various standard sizes and geometries:

TC Blank Types

- Rod blanks – Solid cylinder rods

- Cylinder blanks – Hollow tube shape

- Flat blanks – Rectangular or disc preforms

Standard Sizes

- Diameters from 1mm to 150mm+

- Lengths from 10mm to 300mm+

- Thicknesses up to 50mm

- Custom sizes possible

Common Geometries

- Solid round rod blanks

- Hollow cylinders

- Flat discs, rectangles

- Rings, bushings

- Cut steel blanks

- Precision ground blanks

China factories offer the capability to produce carbide blanks in a wide range of standard and custom sizes and shapes as required.

Grades of Tungsten Carbide Blanks

Tungsten carbide grades are categorized by properties based on cobalt content, additives, grain size etc:

Common TC Blank Grades

| Grade | Hardness | Strength | Toughness | Description |

|---|---|---|---|---|

| C1/K01 | 90 HRA | Medium | Medium | General purpose |

| C2/K10 | 92 HRA | Medium | Medium | Good wear resistance |

| C3/K20 | 94 HRA | Medium | Low | High wear and abrasion resistance |

| C4/K30 | 96 HRA | High | Low | Excellent wear performance |

| C5/K40 | 97 HRA | High | Low | Extreme wear resistance |

- Higher cobalt content improves toughness and shock resistance.

- Smaller grain sizes increase hardness and wear performance.

- Ultra-fine grained carbide reaches extreme hardness values.

- Customized compositions are possible for target application needs.

- Binderless carbide removes the cobalt for pure tungsten carbide.

Selecting the optimal grade depends on balancing wear performance, brittleness, and machining requirements for the part.

Quality Considerations for China Carbide Blanks

Key aspects of quality control for China tungsten carbide blanks:

- Raw materials selection – virgin tungsten vs reclaimed

- Consistent cobalt/tungsten ratio and binding

- Control of carbon content for pure tungsten carbide

- Grain size uniformity and microcrack elimination

- Standards for concentricity and surface finish

- Dimensional accuracy and precision grinding

- Minimal voids or porosity in the blank matrix

- Testing of hardness, transverse rupture strength (TRS)

- Standards conformance based on ISO, ASTM, JIS

- Reputable certifications – CE, RoHS

- Reliable and validated suppliers

Careful controls by manufacturers in these areas ensures high quality carbide blanks suitable for critical applications. Customers should review production methods and implement quality inspection and testing procedures.

Uses and Applications of Tungsten Carbide Blanks

The primary applications of tungsten carbide round blanks after machining include:

Tungsten Carbide Blank Uses

- Cutting tools – Inserts, drills, end mills, burrs

- Forming and stamping dies

- Bearings and press rolls

- Nozzles and valve inserts

- Industrial tooling – Pelletizing, wire drawing

- Wear parts – Seals, bushings

- Textile equipment – Needles, reeds

- Mining and construction – Drill tips, rock bits

- Automotive – Fuel injection, valves, seals

- Extrusion of plastics and polymers

- Food processing equipment components

Tungsten carbide’s extreme hardness allows it to outlast steel, stainless, and cobalt tooling in demanding applications involving high wear, pressures, and temperatures. Machining blanks into parts provides design flexibility.

Cost Analysis of China Carbide Blanks

Tungsten carbide round blank pricing depends on:

China TC Blank Cost Drivers

- Carbide grade selected

- Dimensions and tolerance requirements

- Purchase volumes and minimum order quantity

- Raw tungsten costs and availability

- Processing method used by the supplier

- Finishing operations like grinding

- Supplier margins and location

China TC Blank Price Range

- $5 to $30 per kg for common sizes and grades

- Larger sizes over 100mm diameter up to $50/kg

- Precision ground blanks up to $100/kg

- Cut steel blanks for inserts up to $80/kg

- Minimum order is typically 100 kg

- Reduced costs at higher purchase volumes

Sourcing China tungsten carbide provides significant cost savings over domestic suppliers for most buyers.

Leading Suppliers of Tungsten Carbide Blanks in China

Some major China manufacturers and exporters of tungsten carbide blanks include:

China TC Blank Manufacturers

- Zhuzhou Jinggong Cemented Carbide Co.

- Zhuzhou Kennametal Hard Alloy Co.

- Zhuzhou Meetyou Carbide Co.

- tuned Group

- ZWEX

- Shengda Hard Alloy

- Zhuzhou Xinhua Cemented Carbide Cutting Tools

- ZCCCT

- Zhongchang International Tungsten Industry

- Chongyi Zhangyuan Tungsten Co

These producers offer a full range of tungsten carbide blanks at competitive export pricing and large production capabilities. Most are located in the major tungsten industry hub of Zhuzhou City. Custom formulations and geometries can be sourced to specification at certain factories.

Key Considerations When Buying China Carbide Blanks

Buyers evaluating China tungsten carbide blank suppliers should consider:

- Producer’s experience and manufacturing expertise

- Range of grades and blank geometries offered

- Quality control and testing procedures

- Compliance with international standards

- Reliability of delivery logistics to destination

- Willingness to provide samples for evaluation

- Responsiveness to requests and technical support

- Past customer reviews and satisfaction

- Competitive pricing and minimum order quantities

- Agreement to purchasing terms and conditions

Visiting a shortlist of suppliers in person allows verification of production capabilities and building relationships. This ensures a trustworthy source of blanks tailored to the buyer’s needs.

Pros and Cons of China Tungsten Carbide Blanks

Advantages of China Carbide Blanks

- Significant cost savings over domestic sources

- Large production volumes and inventory available

- Variety of standard and custom geometries

- Multiple carbide grades to choose from

- Improved downstream machining economics

- Technical assistance from factories

Potential Drawbacks

- Ensuring material quality consistency

- Language barriers with suppliers

- Need for developing trusted supply chain source

- Shipping lead times from China

- Minimum order quantities may be large

The lower costs outweigh difficulties for most buyers. Careful supplier selection and working to qualify China carbide material can yield major advantages.

Conclusion

Tungsten carbide blanks from China provide buyers with an economical starting material for machining into high-wear components while taking advantage of tungsten carbide’s performance properties. A range of standard and custom geometries and grades are available from China’s major tungsten producers. By implementing robust quality control measures and finding reliable suppliers, manufacturers can realize major cost benefits over domestic tungsten carbide material. The superior wear resistance expands the life of tooling, dies and components across many industries.