Introduction

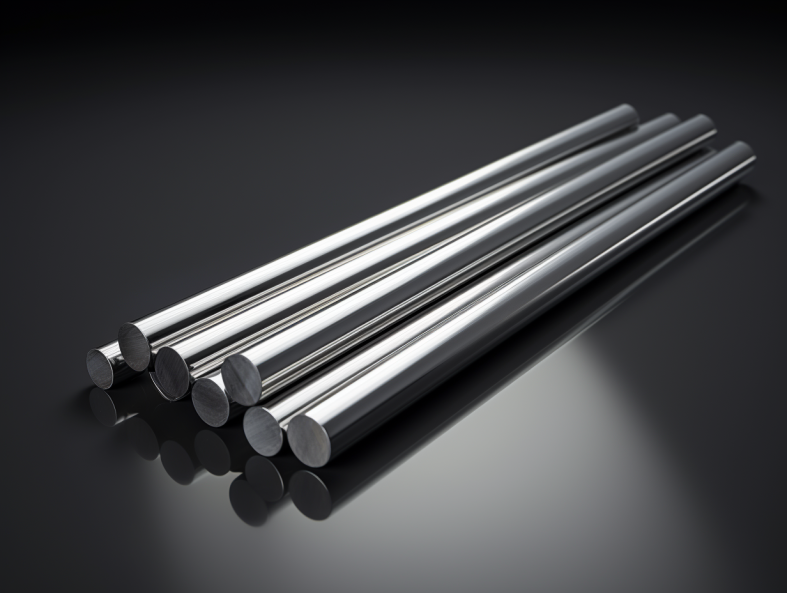

Overview of carbide rods

China K20 carbide rod is a high-quality and durable tool used in various industries. It is made from a combination of tungsten and carbon, which gives it excellent hardness and wear resistance. The rod is commonly used in metalworking applications, such as drilling, milling, and cutting. Its superior strength and toughness make it ideal for machining hard materials like stainless steel, cast iron, and titanium. Additionally, the China K20 carbide rod offers high thermal conductivity, allowing for efficient heat dissipation during machining operations. Overall, this carbide rod is a reliable and efficient tool that enhances productivity and precision in industrial processes.

Importance of carbide rods in various industries

Carbide rods play a crucial role in various industries due to their exceptional properties and durability. These rods, specifically the China K20 carbide rod, are widely used in applications such as metalworking, woodworking, mining, and construction. The importance of carbide rods lies in their ability to withstand high temperatures, resist wear and corrosion, and provide excellent cutting performance. In metalworking, carbide rods are essential for machining processes, enabling precise and efficient cutting of various materials. In woodworking, these rods are utilized for shaping and cutting wood with precision and accuracy. Moreover, the mining and construction industries rely on carbide rods for drilling, excavation, and rock cutting due to their strength and toughness. Overall, carbide rods, especially the China K20 carbide rod, are indispensable tools that significantly enhance productivity and quality in numerous industries.

Brief history of carbide rod manufacturing

Carbide rod manufacturing has a rich and fascinating history, with China playing a significant role in its development. The production of carbide rods in China dates back several decades, with the country becoming a major player in the industry. Over the years, Chinese manufacturers have perfected the manufacturing process, ensuring the production of high-quality carbide rods. Today, China is known for its expertise in producing K20 carbide rods, which are widely used in various industries such as metalworking, woodworking, and mining. The continuous advancements in technology and the commitment to innovation have made China a leading hub for carbide rod manufacturing, contributing to the growth and success of industries worldwide.

Properties of China K20 Carbide Rod

Composition and structure

The composition and structure of the China K20 carbide rod play a crucial role in its performance and durability. This carbide rod is made up of a combination of tungsten carbide and cobalt, which gives it excellent hardness and strength. The tungsten carbide provides high wear resistance, while the cobalt acts as a binder, holding the carbide particles together. The rod has a fine-grained structure, which enhances its toughness and resistance to cracking. This composition and structure make the China K20 carbide rod suitable for various applications, including cutting tools, wear parts, and drilling equipment.

Hardness and toughness

The hardness and toughness of the China K20 carbide rod are key characteristics that make it a highly sought-after material. With a hardness rating of [insert hardness rating], the rod is able to withstand extreme wear and tear, making it ideal for applications that require high durability. Additionally, the rod exhibits impressive toughness, allowing it to resist breakage and deformation even under heavy loads. This combination of hardness and toughness sets the China K20 carbide rod apart from other materials, making it a top choice for various industrial and manufacturing processes.

Wear resistance and heat resistance

China K20 carbide rod is known for its exceptional wear resistance and heat resistance. It is a high-performance material that can withstand extreme conditions and maintain its strength and durability. The carbide rod is specifically designed to resist wear and tear, making it ideal for applications that involve cutting, drilling, and machining. Additionally, its heat resistance allows it to withstand high temperatures without losing its structural integrity. This makes the China K20 carbide rod a reliable choice for industries such as aerospace, automotive, and manufacturing, where wear resistance and heat resistance are paramount.

Applications of China K20 Carbide Rod

Cutting tools

China K20 carbide rod is widely used in cutting tools due to its exceptional hardness and durability. It is a high-performance material that can withstand high temperatures and maintain its sharpness for a longer period of time. The carbide rod is commonly used in the manufacturing industry for applications such as milling, drilling, and turning. Its superior strength and wear resistance make it an ideal choice for cutting tools, providing efficient and precise cutting performance. With the increasing demand for high-quality cutting tools, the China K20 carbide rod has become a popular choice among professionals in various industries.

Milling and drilling applications

China K20 carbide rod is widely used in milling and drilling applications. With its exceptional hardness and wear resistance, it is able to withstand the high speeds and pressures involved in these processes. The rod’s superior strength and durability make it an ideal choice for cutting through tough materials such as metal, wood, and plastic. Additionally, its high heat resistance ensures that it remains stable and effective even under extreme temperatures. Whether it’s for industrial or DIY projects, the China K20 carbide rod is a reliable and efficient tool that delivers excellent results in milling and drilling applications.

Metalworking and manufacturing

Metalworking and manufacturing play a crucial role in various industries, including the production of the China K20 carbide rod. With its exceptional hardness and wear resistance, the K20 carbide rod is widely used in cutting, drilling, and milling applications. It is a vital component in the metalworking process, enabling precise and efficient machining operations. The manufacturing of the K20 carbide rod involves advanced techniques and quality control measures to ensure its durability and performance. As a result, it has become a preferred choice for professionals in the metalworking industry, contributing to the overall growth and development of the manufacturing sector.

Advantages of China K20 Carbide Rod

High precision and accuracy

China K20 carbide rod is known for its high precision and accuracy. It is widely used in various industries, including manufacturing, automotive, and aerospace. The rod is made from high-quality carbide material, ensuring its durability and long lifespan. With its exceptional hardness and wear resistance, the K20 carbide rod can withstand the most demanding cutting and milling applications. Its precise dimensions and tight tolerances make it an ideal choice for producing high-quality components and achieving excellent surface finishes. Whether it’s for drilling, reaming, or threading, the China K20 carbide rod delivers consistent performance and superior results. With its outstanding performance and reliability, it has become a preferred choice for professionals and industries worldwide.

Long tool life

The China K20 carbide rod offers exceptional tool life, making it an ideal choice for various machining applications. With its superior hardness and wear resistance, this carbide rod can withstand the toughest cutting conditions, ensuring extended tool life and reduced downtime. Whether used for milling, drilling, or turning, the K20 carbide rod delivers consistent performance and precision, allowing for high-quality and efficient machining operations. Its durability and longevity make it a cost-effective solution for industries such as automotive, aerospace, and manufacturing. When it comes to long tool life, the China K20 carbide rod is a reliable and trusted option.

Cost-effectiveness

The cost-effectiveness of the China K20 carbide rod is one of its key advantages. With its high durability and long lifespan, the carbide rod offers excellent value for money. Compared to other carbide rods in the market, the China K20 carbide rod provides superior performance at a more affordable price. This makes it a popular choice among manufacturers and industries looking for a cost-effective solution for their cutting and machining needs. Additionally, the China K20 carbide rod’s exceptional wear resistance ensures minimal tool downtime and reduced maintenance costs, further enhancing its cost-effectiveness.

Manufacturing Process of China K20 Carbide Rod

Raw material selection

When it comes to the manufacturing of the China K20 carbide rod, raw material selection plays a crucial role. The quality and performance of the carbide rod largely depend on the materials used in its production. Therefore, meticulous attention is given to choosing the right raw materials. Only the finest quality materials, known for their durability and strength, are selected to ensure the longevity and reliability of the carbide rod. By carefully selecting the raw materials, manufacturers can guarantee that the China K20 carbide rod meets the highest standards and delivers exceptional performance in various applications.

Mixing and grinding

In the process of mixing and grinding, the China K20 carbide rod plays a crucial role. This high-quality rod is designed to withstand the demanding conditions of the mixing and grinding process, ensuring optimal performance and durability. With its exceptional hardness and wear resistance, the China K20 carbide rod effectively grinds and mixes various materials, including metals, ceramics, and composites. Its superior strength and toughness enable it to withstand the intense forces and vibrations generated during the mixing and grinding process, resulting in precise and efficient material preparation. Whether used in industrial applications or research laboratories, the China K20 carbide rod is a reliable and indispensable tool for achieving consistent and high-quality mixing and grinding outcomes.

Sintering and shaping

Sintering and shaping are critical processes in the production of China K20 carbide rods. Sintering involves heating the raw materials, typically tungsten carbide powder and a binder, to a high temperature to form a solid mass. This process helps to enhance the strength and hardness of the carbide rods. Shaping, on the other hand, involves forming the sintered mass into the desired rod shape through various techniques such as extrusion or pressing. The shaping process ensures that the carbide rods have the correct dimensions and surface finish. Both sintering and shaping play a crucial role in determining the quality and performance of China K20 carbide rods, making them suitable for applications in cutting tools, wear-resistant components, and other industrial applications.

Conclusion

Summary of key points

The China K20 carbide rod is a high-quality tool used in various industries. It is known for its exceptional hardness and wear resistance, making it ideal for cutting, drilling, and milling applications. This carbide rod is made from a combination of tungsten carbide and cobalt, which gives it superior strength and durability. Additionally, it has excellent heat resistance, allowing it to withstand high temperatures without losing its cutting performance. The China K20 carbide rod is widely used in the manufacturing and metalworking sectors, providing efficient and precise results. Overall, it is a reliable and versatile tool that plays a crucial role in enhancing productivity and performance in various industrial processes.

Future prospects of China K20 carbide rod

The future prospects of China K20 carbide rod are promising. With its excellent hardness and wear resistance, the K20 carbide rod has a wide range of applications in various industries such as automotive, aerospace, and manufacturing. As the demand for high-quality cutting tools and precision components continues to grow, the market for K20 carbide rod is expected to expand. Additionally, China’s strong manufacturing capabilities and cost advantages make it a key player in the global carbide rod market. With continuous advancements in technology and innovation, the future of China K20 carbide rod looks bright.

Closing thoughts

In conclusion, the China K20 carbide rod offers exceptional quality and durability. Its superior performance and long lifespan make it a reliable choice for various industrial applications. Whether used in machining, metalworking, or woodworking, this carbide rod delivers precise and efficient results. Additionally, its affordable price point makes it an attractive option for both small businesses and larger manufacturing companies. With the China K20 carbide rod, you can expect consistent performance and excellent value for your investment.