Introduction

Overview of China H6 Polished Carbide Rods

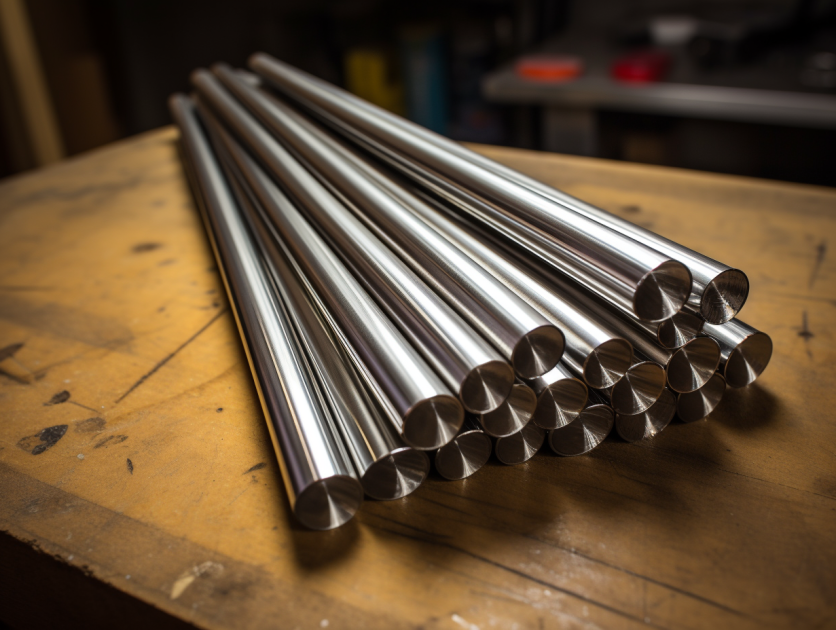

China H6 polished carbide rods are high-quality tools that are widely used in various industries. These rods are made from high-grade carbide material, which ensures their durability and strength. The polished surface of the rods enhances their performance and efficiency. With precise dimensions and excellent finish, these carbide rods are ideal for applications that require high precision and accuracy. They are commonly used in metalworking, woodworking, and other machining processes. The China H6 polished carbide rods offer excellent resistance to wear and can withstand high temperatures, making them suitable for use in demanding environments. Overall, these rods are a reliable choice for professionals who seek superior quality and performance in their cutting and drilling operations.

Importance of H6 Polished Carbide Rods in Various Industries

H6 polished carbide rods play a crucial role in various industries due to their exceptional durability and performance. These rods are widely used in manufacturing processes that require high precision and strength, such as metalworking, woodworking, and automotive industries. The H6 polished surface finish ensures smooth and accurate machining, resulting in superior product quality. Additionally, the carbide material used in these rods offers excellent resistance to wear and corrosion, making them ideal for long-lasting and reliable performance. With their versatility and reliability, H6 polished carbide rods have become an essential component in many industries, contributing to increased productivity and efficiency.

Purpose of the Article

The purpose of the article is to provide an in-depth analysis of China’s H6 polished carbide rods. These rods are widely used in various industries, including manufacturing, construction, and engineering. The article aims to explore the features, benefits, and applications of H6 polished carbide rods, highlighting their superior quality and performance. Additionally, it will discuss the manufacturing process, materials used, and the importance of using high-quality carbide rods in industrial applications. The article will also touch upon the market demand for H6 polished carbide rods in China and globally, showcasing the country’s significant contribution to the carbide rod industry. Overall, the article seeks to educate readers about the significance and advantages of China’s H6 polished carbide rods in the industrial sector.

Properties of H6 Polished Carbide Rods

Composition and Structure

The composition and structure of China H6 polished carbide rods play a crucial role in their performance and durability. These rods are primarily composed of tungsten carbide, which is known for its exceptional hardness and wear resistance. The tungsten carbide is combined with a small percentage of cobalt, which acts as a binder to hold the carbide particles together. This combination results in a material that is extremely tough and resistant to deformation. Additionally, the rods are carefully engineered to have a uniform microstructure, ensuring consistent performance and reliability. The precise composition and structure of China H6 polished carbide rods make them ideal for various industrial applications, such as machining, drilling, and cutting, where high strength and wear resistance are essential.

Hardness and Wear Resistance

China H6 polished carbide rods are known for their exceptional hardness and wear resistance. These rods are manufactured using high-quality carbide materials, which undergo a rigorous polishing process to ensure a smooth and flawless surface. The hardness of these rods allows them to withstand heavy loads and high temperatures without deforming or wearing out easily. Additionally, their exceptional wear resistance ensures a longer lifespan, making them ideal for various industrial applications such as metalworking, machining, and cutting. Whether it’s for precision tooling or heavy-duty applications, China H6 polished carbide rods are a reliable choice that delivers superior performance and durability.

Heat Resistance and Thermal Conductivity

The China H6 polished carbide rods exhibit excellent heat resistance and thermal conductivity. These rods are specifically designed to withstand high temperatures and maintain their structural integrity. The unique composition of the carbide material allows for efficient heat transfer, making them ideal for applications that require precise temperature control. Additionally, the polished surface of the rods enhances their thermal conductivity, ensuring optimal heat dissipation. Whether used in industrial machinery or cutting tools, the China H6 polished carbide rods are a reliable choice for demanding heat-intensive environments.

Applications of H6 Polished Carbide Rods

Metalworking and Machining

Metalworking and machining are essential processes in the manufacturing industry. These processes involve shaping and forming metal materials into desired shapes and sizes. One important component used in metalworking and machining is the China H6 polished carbide rods. These rods are known for their high hardness, wear resistance, and excellent performance in cutting and grinding applications. They are widely used in various industries, including automotive, aerospace, and machinery manufacturing. The China H6 polished carbide rods play a crucial role in ensuring precision and efficiency in metalworking and machining operations. With their superior quality and durability, they are trusted by professionals worldwide for achieving consistent and high-quality results. Whether it’s for drilling, milling, or turning, the China H6 polished carbide rods are a reliable choice for achieving optimal performance in metalworking and machining processes.

Mining and Construction

China is a leading producer of H6 polished carbide rods, which are widely used in the mining and construction industries. These rods are known for their exceptional strength, durability, and resistance to wear and tear. They are specifically designed to withstand the harsh conditions and heavy loads encountered in mining and construction operations. The H6 polished carbide rods from China are manufactured using advanced technology and high-quality materials, ensuring superior performance and reliability. With their excellent performance characteristics, these rods play a crucial role in enhancing the efficiency and productivity of mining and construction projects. Whether it’s drilling, cutting, or crushing, the H6 polished carbide rods from China are the go-to choice for professionals in the industry.

Woodworking and Furniture Manufacturing

China H6 polished carbide rods are essential tools in the woodworking and furniture manufacturing industry. These high-quality rods are known for their durability and precision, making them perfect for cutting and shaping wood. With their superior hardness and strength, they can withstand the demands of heavy-duty woodworking tasks. Whether it’s creating intricate designs or constructing large furniture pieces, these carbide rods provide the reliability and performance needed to achieve professional results. Woodworkers and furniture manufacturers can rely on China H6 polished carbide rods to enhance their craftsmanship and produce top-notch products.

Advantages of H6 Polished Carbide Rods

Longevity and Durability

China H6 polished carbide rods are known for their exceptional longevity and durability. These rods are manufactured using high-quality materials and advanced technology, ensuring that they can withstand even the most demanding applications. Whether used in machining, drilling, or cutting, these carbide rods offer superior performance and reliability. Their polished surface further enhances their durability, making them resistant to wear and corrosion. With their long lifespan, these rods provide cost-effective solutions for various industries, including automotive, aerospace, and manufacturing. Invest in China H6 polished carbide rods for long-lasting and dependable performance.

High Precision and Performance

China H6 polished carbide rods are known for their high precision and performance. These rods are meticulously crafted to meet the strictest quality standards, ensuring optimal performance in various industrial applications. With their exceptional hardness and wear resistance, these carbide rods are highly durable and can withstand extreme conditions. Whether it’s for precision machining, tooling, or other specialized applications, these carbide rods deliver consistent and reliable results. Made from top-grade materials and manufactured using advanced techniques, China H6 polished carbide rods are a reliable choice for professionals seeking precision and performance.

Cost-effectiveness and Efficiency

The cost-effectiveness and efficiency of China H6 polished carbide rods make them an excellent choice for various applications. These rods are manufactured using high-quality materials and advanced technology, ensuring their durability and performance. With their precise dimensions and excellent wear resistance, China H6 polished carbide rods offer a long service life, reducing the need for frequent replacements. Additionally, their high thermal stability allows them to withstand high temperatures without compromising their performance. This makes them ideal for use in industries such as manufacturing, construction, and metalworking, where cost-effectiveness and efficiency are crucial factors. Overall, China H6 polished carbide rods provide a reliable and cost-effective solution for a wide range of applications.

Manufacturing Process of H6 Polished Carbide Rods

Raw Material Selection

When it comes to the raw material selection for China H6 polished carbide rods, careful consideration is given to ensure the highest quality and performance. The rods are made from premium carbide materials, known for their exceptional hardness, strength, and durability. This ensures that the carbide rods can withstand the most demanding applications and provide long-lasting performance. Additionally, the raw materials are sourced from reliable suppliers who adhere to strict quality control measures, further guaranteeing the consistency and reliability of the final product. By prioritizing raw material selection, China H6 polished carbide rods are able to deliver superior performance and reliability in various industrial applications.

Powder Mixing and Compaction

Powder mixing and compaction play a crucial role in the production of China H6 polished carbide rods. The process begins with carefully selecting the appropriate powders, which are then mixed together to ensure a homogeneous composition. This ensures that the carbide rods have consistent properties and performance. After the mixing process, the powder is compacted using specialized equipment to achieve the desired density and shape. This step is essential to enhance the strength and durability of the carbide rods. Overall, the powder mixing and compaction process is a critical stage in the manufacturing of China H6 polished carbide rods, ensuring their quality and performance.

Sintering and Polishing

Sintering and polishing are crucial steps in the production of China H6 polished carbide rods. Sintering involves the process of compacting and forming the carbide powder into a solid mass using high temperatures and pressure. This helps to enhance the strength and durability of the rods. Once the sintering process is complete, the rods undergo polishing to achieve a smooth and shiny surface finish. Polishing not only enhances the aesthetic appeal of the rods but also improves their performance by reducing friction and wear. The combination of sintering and polishing ensures that China H6 polished carbide rods meet the highest quality standards and provide excellent performance in various industrial applications.

Conclusion

Summary of Key Points

The article titled ‘China H6 Polished Carbide Rods’ provides a comprehensive overview of the key points related to this specific product. It highlights the features, applications, and benefits of using H6 polished carbide rods manufactured in China. The article emphasizes the superior quality, durability, and precision of these rods, making them ideal for various industries such as manufacturing, automotive, and aerospace. Additionally, it discusses the competitive pricing and reliable supply chain of these carbide rods, making them a cost-effective and reliable choice for businesses. Overall, the article serves as an informative guide for readers interested in understanding the significance and advantages of China’s H6 polished carbide rods.

Future Prospects of H6 Polished Carbide Rods

The future prospects of H6 polished carbide rods look promising. With the increasing demand for high-quality cutting tools in various industries, the use of H6 polished carbide rods is expected to grow significantly. These rods offer superior hardness, wear resistance, and toughness, making them ideal for applications that require precision cutting and machining. Additionally, the advancements in manufacturing technology are further enhancing the performance and durability of H6 polished carbide rods. As a result, they are becoming the preferred choice for tool manufacturers and end-users alike. Moreover, the growing focus on sustainability and environmental-friendly practices is driving the adoption of H6 polished carbide rods, as they are known for their long lifespan and recyclability. In conclusion, the future of H6 polished carbide rods looks bright, with an increasing market demand and continuous advancements in technology.

Closing Remarks

In conclusion, the China H6 polished carbide rods offer exceptional quality and durability. With their precise manufacturing and high-performance capabilities, these rods are an excellent choice for various industrial applications. Whether you are in the automotive, aerospace, or machining industry, the China H6 polished carbide rods will meet your needs and exceed your expectations. Their superior strength and resistance to wear make them a reliable tool for cutting, drilling, and shaping materials. Invest in the China H6 polished carbide rods today and experience the difference they can make in your operations.