Introduction

Definition of Cemented Carbide Rods

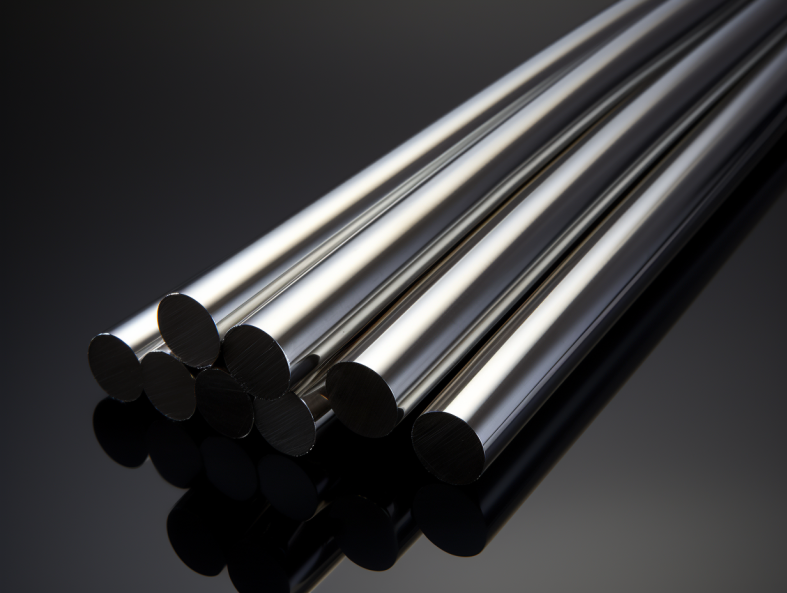

Cemented carbide rods, also known as tungsten carbide rods, are a type of cutting tool material widely used in various industries. These rods are made by combining tungsten carbide particles with a binder material, such as cobalt or nickel, through a process called sintering. The resulting material is extremely hard and wear-resistant, making it ideal for applications that require high cutting speeds and long tool life. Cemented carbide rods are commonly used in the manufacturing of drills, end mills, reamers, and other cutting tools. They provide excellent performance in machining operations, offering superior strength, toughness, and heat resistance. With their exceptional hardness and durability, cemented carbide rods have become an essential component in the production of high-quality cutting tools for the machining industry.

History of Cemented Carbide Rods

Cemented carbide rods have a rich history that dates back several decades. The development of cemented carbide as a material began in the early 20th century, with researchers in various countries working to create a hard and durable material that could be used in a wide range of applications. However, it was in China where significant advancements were made in the production of cemented carbide rods. Chinese scientists and engineers pioneered the development of new manufacturing techniques, allowing for the production of high-quality cemented carbide rods that are widely used in industries such as mining, construction, and machining. Today, China is one of the leading producers and exporters of cemented carbide rods, contributing to the growth and development of various industries around the world.

Applications of Cemented Carbide Rods

Cemented carbide rods have a wide range of applications in various industries. One of the main applications of cemented carbide rods is in the manufacturing of cutting tools. These rods are known for their exceptional hardness and wear resistance, making them ideal for cutting and shaping materials such as metal, wood, and plastic. Additionally, cemented carbide rods are also used in the production of mining and drilling tools, where their high strength and durability are essential. Furthermore, these rods find applications in the automotive industry for the production of wear-resistant parts and components. Overall, the versatility and performance of cemented carbide rods make them indispensable in numerous industrial applications.

Composition and Manufacturing Process

Raw Materials Used in Cemented Carbide Rods

Cemented carbide rods are manufactured using a combination of high-quality raw materials. These materials include tungsten carbide, cobalt, and other trace elements. Tungsten carbide is the main component, providing exceptional hardness and strength to the rods. Cobalt acts as a binder, holding the tungsten carbide particles together and enhancing their toughness. Other trace elements are added to further improve the performance and properties of the cemented carbide rods. The precise composition of the raw materials is carefully controlled to ensure consistent quality and reliable performance of the rods. Overall, the careful selection and use of raw materials play a crucial role in the production of high-quality cemented carbide rods.

Powder Metallurgy Process

The Powder Metallurgy process is widely used in the production of China cemented carbide rods. This process involves the blending of metal powders, such as tungsten carbide and cobalt, followed by compacting the mixture into a desired shape. The compacted shape is then subjected to a high-temperature sintering process, which solidifies the carbide particles and forms a dense and durable material. The Powder Metallurgy process allows for precise control over the composition and microstructure of the cemented carbide rods, resulting in excellent mechanical properties and wear resistance. This manufacturing method has revolutionized the production of cemented carbide rods in China, enabling the production of high-quality and reliable products for various industrial applications.

Sintering and Finishing Techniques

Sintering and finishing techniques play a crucial role in the production of China cemented carbide rods. Sintering is the process of compacting and forming the carbide powder into a solid material through the application of heat and pressure. This step is essential for achieving the desired hardness and strength of the rods. Finishing techniques, on the other hand, involve post-processing methods such as grinding, polishing, and coating to enhance the surface quality and dimensional accuracy of the rods. These techniques ensure that the cemented carbide rods meet the stringent requirements of various industrial applications, including cutting, drilling, and mining. With advanced sintering and finishing techniques, China has become a leading producer of high-quality cemented carbide rods, providing superior performance and durability in demanding working conditions.

Properties and Characteristics

Hardness and Wear Resistance

Cemented carbide rods from China are known for their exceptional hardness and wear resistance. These rods are made by combining tungsten carbide particles with a binder material, typically cobalt. The resulting material is extremely hard and can withstand high temperatures and heavy loads. This makes it ideal for applications that require strength and durability, such as cutting tools, drilling equipment, and wear parts. Additionally, the wear resistance of cemented carbide rods ensures a longer lifespan and reduces the need for frequent replacements, making them a cost-effective choice for various industries. Overall, the hardness and wear resistance of China’s cemented carbide rods make them a reliable and sought-after material for demanding applications.

Strength and Toughness

Strength and toughness are two crucial factors to consider when evaluating the performance of cemented carbide rods. Cemented carbide rods are known for their exceptional strength, allowing them to withstand high levels of stress and pressure. This makes them ideal for applications that require resistance to wear, deformation, and breakage. Additionally, cemented carbide rods exhibit excellent toughness, enabling them to absorb and dissipate energy without fracturing. This combination of strength and toughness makes cemented carbide rods highly durable and reliable, ensuring their effectiveness in various industries such as manufacturing, mining, and construction.

Thermal and Chemical Stability

Thermal and Chemical Stability: One of the key characteristics of China cemented carbide rods is their exceptional thermal and chemical stability. These rods are specifically designed to withstand high temperatures and harsh chemical environments, making them ideal for various industrial applications. Whether it’s in the aerospace, automotive, or manufacturing industry, these carbide rods can maintain their structural integrity and performance even under extreme conditions. The unique composition and manufacturing process of these rods ensure that they can resist thermal expansion, corrosion, and wear, providing long-lasting durability and reliability. With their outstanding thermal and chemical stability, China cemented carbide rods are a reliable choice for demanding applications where performance and longevity are crucial.

Types and Grades

Solid Carbide Rods

Solid carbide rods are a type of tool material commonly used in various industries, including the manufacturing and construction sectors. These rods are made from a combination of tungsten carbide and cobalt, which gives them exceptional hardness and durability. Solid carbide rods are known for their excellent resistance to wear and high temperatures, making them ideal for applications that involve cutting, drilling, and milling. They are widely used in the production of cutting tools, such as drills, end mills, and reamers, as well as in the manufacturing of wear-resistant parts and components. With their superior strength and performance, solid carbide rods have become an essential component in the production processes of many industries, contributing to increased efficiency and productivity.

Tungsten Carbide Rods

Tungsten Carbide Rods are a type of cemented carbide product widely used in various industries. These rods are made by mixing tungsten carbide powder with a binder material and then sintering it at high temperatures. The resulting product is incredibly strong and durable, making it ideal for applications that require high wear resistance and toughness. Tungsten Carbide Rods are commonly used in the manufacturing of cutting tools, such as drills, end mills, and reamers, as well as in the production of wear parts for machinery and equipment. With their exceptional hardness and ability to withstand extreme conditions, these rods play a crucial role in enhancing productivity and efficiency in industrial processes. In addition, Tungsten Carbide Rods have excellent corrosion resistance and can withstand high temperatures, making them suitable for use in harsh environments. Overall, Tungsten Carbide Rods are an essential component in many industries, providing reliable performance and long-lasting durability.

Titanium Carbide Rods

Titanium carbide rods are a type of cemented carbide rods that have gained significant popularity in various industries. These rods are known for their exceptional hardness, wear resistance, and high strength-to-weight ratio. Due to these properties, titanium carbide rods are widely used in the manufacturing of cutting tools, drilling tools, and wear parts. They are also utilized in the aerospace, automotive, and mining industries for their ability to withstand extreme conditions and provide long-lasting performance. With their excellent thermal stability and corrosion resistance, titanium carbide rods have become an essential material in the production of high-performance components. Overall, titanium carbide rods offer superior durability and reliability, making them an ideal choice for demanding applications.

Applications

Metalworking Industry

The Metalworking Industry is a vital sector in the manufacturing field, and China has established itself as a global leader in this industry. One of the key components in metalworking is the use of cemented carbide rods. These rods, made from a combination of tungsten carbide and cobalt, offer superior hardness and wear resistance, making them ideal for various metal cutting and shaping applications. China’s production of cemented carbide rods has been growing steadily, meeting the increasing demand both domestically and internationally. With its advanced manufacturing capabilities and stringent quality control measures, China continues to play a significant role in the metalworking industry through the production of high-quality cemented carbide rods.

Mining and Construction

China is a leading producer and exporter of cemented carbide rods, which are widely used in the mining and construction industries. These rods are known for their exceptional hardness, toughness, and wear resistance, making them ideal for demanding applications in drilling, cutting, and crushing. With China’s abundant reserves of tungsten and other raw materials, coupled with advanced manufacturing techniques, the country has established itself as a major player in the global cemented carbide rod market. The mining and construction sectors heavily rely on these high-quality rods to enhance productivity, efficiency, and safety in various operations, including tunneling, excavation, and rock drilling. As the demand for durable and reliable tools continues to grow, China’s cemented carbide rods are poised to play a crucial role in the advancement of mining and construction worldwide.

Woodworking and Furniture Manufacturing

Woodworking and furniture manufacturing industries heavily rely on China cemented carbide rods for their cutting and shaping needs. These high-quality rods are known for their exceptional hardness and durability, making them ideal for precision cutting and shaping of wood materials. With the use of China cemented carbide rods, woodworking professionals can achieve precise and clean cuts, resulting in superior craftsmanship and finished products. Moreover, these rods offer excellent resistance to wear and chipping, ensuring long-lasting performance even in demanding woodworking applications. As a result, China cemented carbide rods have become a popular choice among woodworking and furniture manufacturing businesses, enabling them to enhance productivity, efficiency, and overall product quality.

Future Trends and Innovations

Advancements in Coating Technologies

Advancements in coating technologies have greatly improved the performance and durability of China cemented carbide rods. These innovative coatings provide enhanced resistance to wear, corrosion, and heat, making the rods more suitable for a wide range of applications. The development of advanced coating materials and techniques has also resulted in improved adhesion and bonding between the coating and the carbide substrate, ensuring long-lasting performance. Additionally, these advancements have allowed for the customization of coatings to meet specific requirements, further enhancing the versatility and effectiveness of China cemented carbide rods in various industries.

Development of New Carbide Grades

The development of new carbide grades has been a significant advancement in the field of cemented carbide rods. These new grades offer improved performance and durability, making them highly sought after in various industries. The research and development efforts have focused on enhancing the hardness, toughness, and wear resistance of the carbide rods. This has resulted in the production of carbide grades that can withstand extreme conditions and provide superior cutting and machining capabilities. With the continuous development of new carbide grades, the applications of cemented carbide rods are expanding, and they are becoming an indispensable tool in industries such as automotive, aerospace, and manufacturing.

Integration with Industry 4.0

Integration with Industry 4.0 is crucial for the success of China’s cemented carbide rod industry. As the world moves towards advanced automation and digitalization, it is imperative for manufacturers to adapt and embrace the principles of Industry 4.0. By integrating their production processes with cutting-edge technologies such as artificial intelligence, robotics, and data analytics, Chinese cemented carbide rod manufacturers can enhance their productivity, efficiency, and competitiveness. Industry 4.0 enables real-time monitoring and control of manufacturing operations, leading to improved quality control and reduced downtime. Additionally, the integration with Industry 4.0 allows for seamless communication and collaboration with other stakeholders in the supply chain, resulting in enhanced transparency and traceability. Overall, the integration of China’s cemented carbide rod industry with Industry 4.0 not only ensures its sustained growth but also positions it as a leader in the global market.