Cemented carbide blanks refer to unfinished metal cutting tool substrates produced by powder metallurgy methods in China. This guide provides an overview of China cemented carbide blanks including materials, manufacturing process, sizes, tolerances, coating, applications, cost analysis, quality considerations, and supplier landscape. It serves as a reference for procurement professionals sourcing custom carbide tool blanks.

Introduction to China Cemented Carbide Blanks

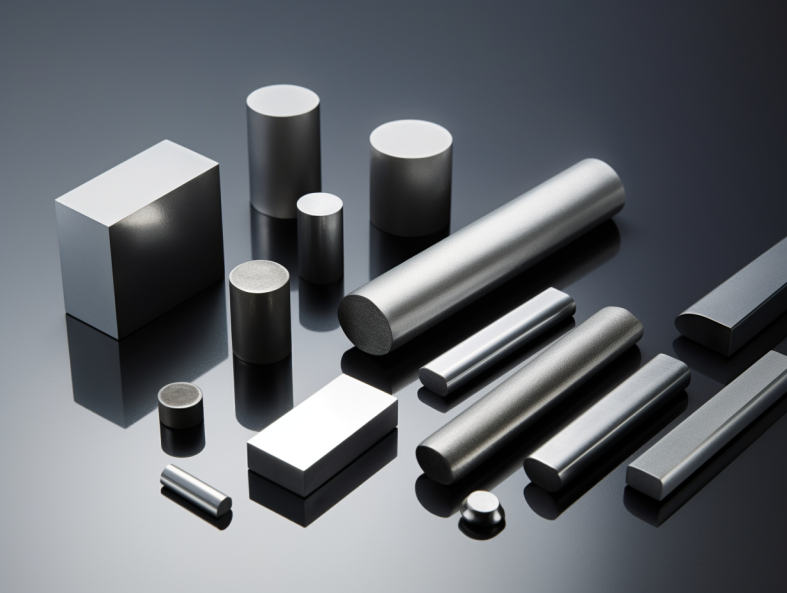

Cemented carbide blanks are compacted shapes made from tungsten carbide-cobalt powder that form the base substrate for cutting tools before final grinding and coating. Blanks enable machining custom tool geometries.

Key benefits of China carbide blanks:

- Broad range of standard and custom blank sizes and shapes

- Allows custom tool design not limited to standard inserts

- Optimized macro and micro grain powders/grades

- High hardness and wear resistance

- Good impact strength from cobalt binder

- Suitable for all precision machining applications

- Lower cost than finished standard inserts

China has become a major supplier of quality carbide blanks for global markets thanks to advanced sintering capabilities and integrated supply chains.

Manufacturing Process for Carbide Blanks

Cemented carbide blanks are produced through powder metallurgy:

Powder Metallurgy Process Steps

- Raw material preparation – crushing, milling, and blending of tungsten carbide, cobalt, and dopant powders

- Compaction – pressing powder into blank shape under high pressure

- Sintering – heating compacted parts to fuse powder into dense structure

- Grinding – machining to tight dimensional tolerances

- Testing – confirm hardness, microstructure and strength

This enables complex shapes with extremely consistent properties tailored to the cutting application.

Standard Cemented Carbide Grades

Carbide tool blanks are available in a wide range of standard grades categorized by properties:

Standard Cemented Carbide Grades

| Grade Type | Characteristics |

|---|---|

| Fine grain | High hardness for steel turning and milling |

| Medium grain | Good toughness for hardened steels |

| Coarse grain | Improved shock resistance |

| Ultrafine grain | Superior wear resistance and edge retention |

| Cermet grades | Higher temperature and machining stability |

Additional specialty grades are engineered for specific workpiece materials like cast iron, aluminum alloys, carbon fiber, and more.

Carbide Blank Sizes

China carbide blank suppliers offer an extensive range of standard and custom blank sizes including:

- Round discs/pucks from 3mm – 250mm+ diameter

- Rectangular and square blanks up to 100x100mm

- Custom polygon shapes

- Solid rods up to 400mm length

- Special profiles for cutting tool shanks

- Thickness ranging from 2mm up to over 25mm

metric sizes from 1mm increments up to several centimeters. Non-standard custom blanks can also be produced subject to order quantities.

Dimensional Tolerances on Blanks

Standard China cemented carbide blank tolerance grades include:

| Tolerance Grade | Diameter Tolerance |

|---|---|

| IT1 | +/- 0.4 mm |

| IT3 | +/- 0.15 mm |

| IT5 | +/- 0.05 mm |

| IT7 | +/- 0.02 mm |

| IT10 | +/- 0.01 mm |

Tighter tolerances on custom blank dimensions are possible but increase machining costs. Talk to suppliers about achieving tolerances suitable for tool design needs.

Carbide Blank Coating Options

China suppliers can apply tool coating on blanks either before shipment or after custom tool machining:

- PVD (Physical Vapor Deposition) – Titanium aluminum nitride, titanium nitride, titanium carbon nitride, chromium nitride

- CVD (Chemical Vapor Deposition) – Diamond, titanium carbide, aluminum oxide

Coatings improve wear resistance, friction reduction, or heat resistance depending on material and thickness.

Applications of Cemented Carbide Blanks

Machining from carbide blanks allows optimized cutting tool designs:

- Custom geometry aids and jigs

- Dental and surgical tools

- Engraving cutters

- Counterbores, countersinks

- Profile tools for routers

- Reamers, broaches

- Special form taps and threading tools

- Miniature micro tools

- Smart phone and tablet machining

- Aerospace and turbine components

Cemented carbide blanks enable specialized cutting tool geometries when standard inserts don’t suffice.

Cost Analysis of Carbide Blanks

Carbide blank pricing depends on:

- Material grade

- Blank dimensions and tolerance grade

- Order quantity

- Coating requirements

- Delivery terms

Carbide blanks range from ~$5 – $50 per piece for common sizes and grades. Custom tooling with complex geometry, exotic grades, special coatings, and expedited delivery incur premium pricing.

Sourcing blanks locally in target markets lowers shipping costs but has higher unit costs for small orders. Larger orders from China offer economy of scale.

Quality Considerations for Carbide Blanks

Ensuring blanks meet specifications requires:

- Trusted suppliers with proven sintering quality

- Review of supplier and third party material certifications

- Sampling and testing of production lots

- Verification of dimensions, squareness, surface finish

- Validation of material hardness and microstructure

Avoid very low budget blank suppliers whose quality and consistency may not be adequate for machining expensive custom cutting tools.

How to Select a China Carbide Blank Supplier

Factors to consider when choosing a blank supplier:

- Range of grades, tolerances, and blank dimensions

- Custom blank manufacturing capabilities

- Inspection reports and quality certifications

- Pricing, minimum order quantities

- Production capacity and lead times

- Experience with cutting tool applications

- Shipping logistics to your location

- Willingness to collaborate on designs

- Responsive customer service

Evaluate China suppliers carefully to identify qualified partners able to consistently deliver quality carbide blanks tailored to your tooling needs.

Popular China Carbide Blank Suppliers

Leading China manufacturers of cemented carbide blanks include:

- Zhuzhou Jinggong Cemented Carbide Co.

- Zhuzhou Mingri Cemented Carbide Co.

- Shandong Best Technology Co.

- Chengdu Bangpu Cemented Carbide Co.

- Guangdong Xianglu Tungsten Industry Co.

- Zigong Cemented Carbide Cutting Tool

- Zhuzhou Lihua Cemented Carbide Co.

- Xi’an Brightway Cemented Carbide Co.

These companies offer a range of in-stock and custom blank options along with export experience.

Future Outlook for Carbide Blanks

Ongoing trends shaping carbide blank innovation include:

- New ultrafine and nano-grain grades with enhanced properties

- Hard coatings like diamond and cubic boron nitride (CBN)

- Just-in-time supply chain models

- Automated sintering and machining

- Additive manufacturing of carbide cutting tools

- More applications machining composites, alloys

With these advancements, expect continued adoption of carbide tooling thanks to improved performance, quality, and cost-effectiveness.

Key Takeaways on China Carbide Blanks

- Substrates for making custom geometry cutting tools

- Powder metallurgy enables diverse blank sizes and geometry

- Range of carbide grades tailored for machining applications

- China a major supplier thanks to integrated supply chain

- Lower costs than pre-made standard inserts

- Quality considerations around material, tolerances, consistency

- Trusted suppliers essential for machining expensive custom tools

- Future innovations expanding carbide tool utility and economy

Sourcing high performance carbide blanks from qualified China suppliers gives tooling designers increased flexibility to engineer optimized cutting solutions.

FAQs

Q: What are the main advantages of carbide blanks vs standard inserts?

A: Carbide blanks allow custom tool geometry optimized for the workpiece that standard inserts cannot provide. Lower costs than specialty inserts.

Q: What tolerances are typical for carbide tool blanks?

A: Most common are IT5 (+-0.05mm) and IT7 (+-0.02mm) for precision tooling. Tighter tolerances are possible.

Q: Are coated blanks or adding coating later better?

A: Coating after custom machining allows optimizing coating for the tool geometry. Pre-coated blanks simplify logistics.

Q: How should carbide blanks be stored?

A: In a clean, dry environment away from temperature extremes. Avoid moisture, oils, and sources of contamination.

Q: What certifications should qualified carbide blank suppliers have?

A: ISO 9001 and ISO 14001. Also look forevidence of rigorous internal QC testing procedures.

Q: Can any standard carbide grade be made into blanks?

A: Yes, leading China suppliers can produce standard or custom grades in blank form for the application.

Q: Are carbidetool blanks environmentally friendly?

A: Yes, powder metallurgy optimizes material use and carbide tools last longer in use reducing overall tool consumption.

Q: What industries use carbide tool blanks the most?

A: Aerospace, automotive, die mold, machinery, medical fields with demanding machining applications.

Q: What safety precautions are needed when machining carbide blanks?

A: Use proper ventilation and wear a respirator mask to avoid breathing fine carbide dust which can pose a lung hazard.

Q: How large can custom carbide blanks be made?

A: China suppliers can produce large blanks over 25mm thickness and diameters over 250mm subject to sintering equipment capacity.