China Carbide Blanks refer to unfinished blocks of cemented carbide that are ground and machined into tools or components. China has become a major global supplier of carbide blanks for applications across automotive, aerospace, oil and gas, machinery, and other industries. This guide provides an in-depth look at China Carbide Blanks in terms of manufacturing, properties, quality considerations, applications, and leading suppliers.

Introduction to China Carbide Blanks

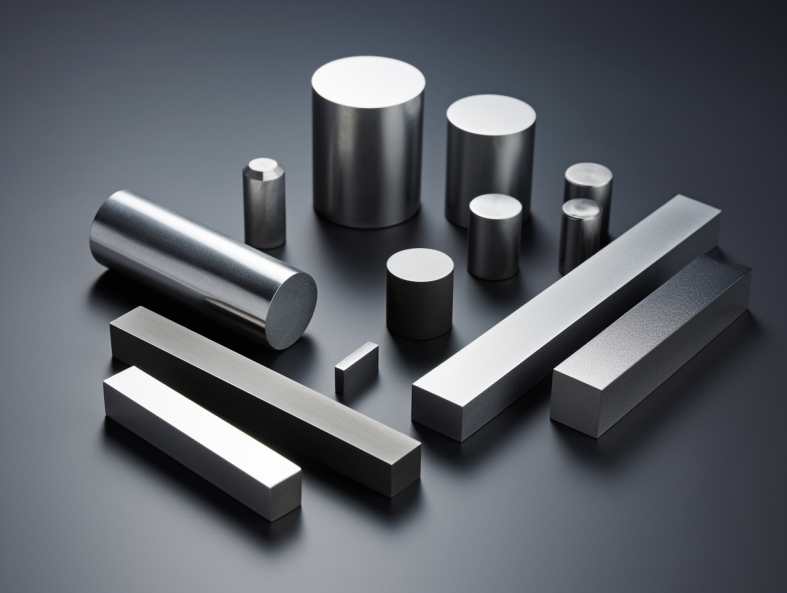

Carbide blanks are solid pieces of cemented carbide alloy that can be fabricated into various tools and wear-resistant parts.

| Type | Description |

|---|---|

| Composition | Tungsten carbide particles in cobalt binder |

| Manufacturing | Powder metallurgy and sintering |

| Sizes | Up to 400mm diameter rods and blocks |

| Finishing | Ground to precise tolerances |

| Applications | Cutting tools, wear parts, extrusion dies |

With their extreme hardness and wear resistance, carbide blanks are an ideal starting material for machining complex carbide components.

Manufacturing Process for Carbide Blanks

Carbide blank production involves:

- Milling – Carbide powder is milled to ensure uniform particle size

- Mixing – Carbide powder is mixed with cobalt binder and wax

- Compacting – The carbide mixture is compressed into a “green” compact

- Sintering – Green compacts are sintered at 1400-1600°C to fuse the powder into dense blanks

- Grinding – The sintered carbide is ground to precise diameters and shapes

- Finishing – Additional lapping and polishing achieves final surface finish

The material properties and performance depend on optimized composition, powder characteristics, sintering temperature, and finishing steps.

Grades of China Carbide Blanks

Carbide blanks are available in various standard grades:

| Grade | Description |

|---|---|

| C1, C2, C3 | General purpose grades for steels |

| C5, C6 | High toughness and shock resistance |

| C4, C7, C8 | For interrupted cuts and abrasive materials |

| C9, C10 | High wear resistance for hard materials |

| P Grades | High precision finish machining |

The grade selection depends on the workpiece material and machining application requirements.

Standard Sizes of Carbide Blanks

Typical sizes of carbide blanks from China:

- Rod blanks from 2mm to 32mm diameter

- Round blanks from 1mm to 150mm diameter

- Square blanks from 2mm to 32mm width

- Rectangular blanks up to 100mm x 150mm

- Custom sizes, shapes and tolerances available

The blanks are ground precisely to standard diameter tolerances between h6 and h11, with surface finishes up to 0.2 Ra μm.

Key Properties of Carbide Blanks

- Extreme hardness – Up to 1600 Vickers hardness provides excellent wear resistance

- High toughness – Good resistance to impact and thermal shock

- High Young’s modulus – Rigidity during cutting and grinding

- Chemical inertness – Resistance to corrosion and oxidation

- High compressive strength – Support heavy loads without distortion

- Thermal conductivity – Reduces thermal expansion and heat buildup

The combination of hardness, toughness, stiffness and strength make carbide blanks ideal for durable cutting tools and wear parts.

Typical Applications of China Carbide Blanks

- Cutting Tools – Drills, endmills, routers, reamers, burrs

- Extrusion Dies – For rods, bars, tubes, wires

- Drawing Dies – For wire, bars, tubes

- Pelletizing Dies – For making fertilizer, animal feed pellets

- Wear Parts – Seals, nozzles, bushes, bearings

- Precision Parts – Measuring gauges, watch parts, pumps

- Mining Tools – Rock drills, mining machinery components

Carbide blanks allow fabricating specialized wear and cutting tools for demanding applications across industries.

Benefits of Using China Carbide Blanks

- Blank shape provides starting material close to final part shape

- Minimizes grinding and machining time/costs

- Consistent quality from standard blank dimensions

- Tailor carbide grade to end application needs

- Technical expertise of blank manufacturer aids selection

- Readily available in range of sizes and grades

Carbide blanks enable easier manufacturing of complex carbide parts compared to other fabrication methods.

Quality Control and Standards

- Composition – Cemented carbide with 6-10% cobalt binder

- Microstructure – Fine, uniform carbide grain structure

- Hardness – Over 90 HRA (1600 Vickers typically)

- Density – Meets or exceeds 14.5 g/cc

- Surface Finish – Up to 0.2 Ra μm

- Dimensional Tolerances – Within specified grade standards

- Defects Testing – Crack, void detection using NDT

- Certifications – ISO 9001, ISO 14001, OHSAS 18001

Reputable Chinese manufacturers follow standardized quality control practices and certification.

Leading Carbide Blank Suppliers in China

Major Chinese exporters of carbide blanks:

| Company | Location |

|---|---|

| Zhuzhou Jinggong Cemented Carbide Co., Ltd. | Zhuzhou, Hunan |

| Zhuzhou Kennametal Hard Alloy Co., Ltd. | Zhuzhou, Hunan |

| Zhuzhou Cemented Carbide Cutting Tools | Zhuzhou, Hunan |

| Suzhou Tianhua Special Alloy Co.,Ltd | Suzhou, Jiangsu |

| Chengdu Bangpu Carbide Blanks Co., Ltd | Chengdu, Sichuan |

China now produces an estimated 80% of the world’s tungsten carbide, enabled by its abundant natural tungsten resources.

Pricing Analysis

Carbide blank pricing depends on:

- Grade and properties like hardness, toughness

- Dimensions and tolerance grades

- Order quantities

- Additional testing/certification needs

- Raw material costs for tungsten and cobalt

Expect to pay $5 – $30 per kg for common standard blank sizes and grades from China.

Selecting a Reliable Carbide Blank Supplier in China

Key considerations when sourcing from Chinese suppliers:

- Experience and years in business

- Range of grades and blank sizes offered

- Stringent quality control and testing capability

- Certifications like ISO 9001

- Price competitiveness on bulk orders

- Overseas shipping experience and logistics infrastructure

- Responsiveness to requests and technical support

- Reputation based on customer reviews

Choosing an established carbide manufacturer reduces potential quality issues and results in a trouble-free procurement experience.

Shipping and Export Procedures

- Pack in sturdy wooden crates to prevent impact damage

- Include product documentation and export declarations

- Fumigate crates for international shipping if required

- Load containers carefully to avoid movement/shifting during transit

- Maritime shipping most economical for large volumes

- Air shipping faster for urgent or small orders

Reputable suppliers can handle exporting formalities, packing, shipping and customs clearance.

FAQs

| Question | Answer |

|---|---|

| What are carbide blanks used for? | Mainly used as starting material for manufacturing carbide cutting tools, wear parts, extrusion dies. |

| What are the contents of carbide blanks? | Tungsten carbide particles in a cobalt binder matrix. Small amounts of titanium, tantalum or niobium may also be present. |

| What industries use carbide blanks? | Automotive, aerospace, oil and gas, construction, metalworking, mining, die and mold industries use carbide blanks. |

| What tolerance grades are available? | Carbide blanks are available from h6 to h11 tolerance grades. |

| Is special tooling needed to machine carbide blanks? | Yes, diamond grinding wheels and tooling is ideal for machining very hard carbide blanks. |

Conclusion

China has become a top global supplier of tungsten carbide blanks catering to diverse industries in machining, tooling, metalforming and mining. With control of raw material supply chains and heavy investments in powder metallurgy manufacturing, China delivers cost-competitive carbide blanks while maintaining consistent quality standards. Stringent supplier selection along with effective logistics and shipping enables overseas buyers to access the full range of Chinese carbide blanks for fabrication of wear and cutting tools.