Overview

Cemented carbide rods, also known as tungsten carbide rods, have emerged as a cornerstone in modern industrial applications due to their unparalleled hardness, wear resistance, and durability. These rods have transformed machining, drilling, and other precision-requiring tasks. This comprehensive guide explores the world of cemented carbide rods, detailing their properties, working principles, usage, processing methods, classifications, and market trends. Whether you’re an industry veteran or a newcomer, this article provides valuable insights into the remarkable capabilities of cemented carbide rods.

Detailed Introduction

What Are Cemented Carbide Rods?

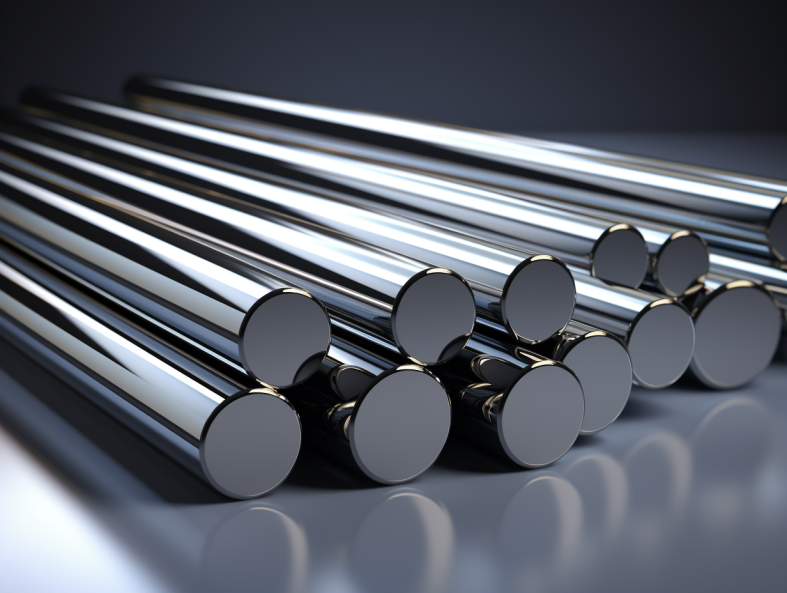

Cemented carbide rods are cylindrical tools created from a composite material composed of tungsten carbide particles bonded with a metallic binder, typically cobalt. This combination yields a material of extraordinary hardness and wear resistance, making it ideal for various industrial applications.

Working Principle

The effectiveness of cemented carbide rods lies in their unique material properties:

- Hardness: Tungsten carbide is one of the hardest materials available, providing exceptional cutting and machining capabilities.

- Wear Resistance: High wear resistance enables the rods to endure extreme conditions and maintain their integrity over extended periods.

- Thermal Stability: These rods retain their hardness even at high temperatures, making them suitable for high-speed machining and demanding applications.

- Corrosion Resistance: Their resistance to corrosion extends the rods’ lifespan in harsh environments.

How to Use Cemented Carbide Rods

Cemented carbide rods are versatile and used in numerous applications, including:

- Cutting Tools: Used in end mills, drill bits, and reamers for precise material removal.

- Mining and Construction Tools: Utilized in rock drilling equipment and construction blades.

- Wear Parts: Employed in machinery as valve seats, nozzles, and other components.

- Precision Components: Used in measuring tools, punches, and dies.

- Medical Instruments: Incorporated in surgical and dental tools for their precision and reliability.

Processing Methods

The processing of cemented carbide rods involves several critical stages:

- Powder Mixing: Combining tungsten carbide powder with a binder metal, usually cobalt.

- Pressing: Shaping the mixture into rods using a pressing machine.

- Sintering: Heating the pressed rods to a high temperature to bond the particles together.

- Grinding: Precision grinding to achieve the desired dimensions and surface finish.

- Coating: Applying advanced coatings to enhance performance and longevity.

Classification and Varieties

Cemented carbide rods are classified based on their composition, grain size, and application. Common classifications include:

- Micro Grain: For applications requiring high precision and sharpness.

- Medium Grain: Balances toughness and wear resistance, suitable for general use.

- Coarse Grain: For applications demanding high toughness and impact resistance.

Market Dynamics

The market for cemented carbide rods is robust and expanding, driven by increasing demand in manufacturing, mining, and medical industries. Key trends include:

- Technological Advancements: Innovations in coating technologies and material formulations.

- Sustainability: Growing emphasis on recycling and eco-friendly production processes.

- Globalization: Expansion of markets in emerging economies, leading to increased competition and innovation.

Product Information

The following table provides detailed information on cemented carbide rods, including types, composition, properties, features, specifications, sizes, grades, and standards.

| Type | Composition | Properties | Features | Specifications | Sizes | Grade | Standards |

|---|---|---|---|---|---|---|---|

| Micro Grain | WC + Co (5-8%) | High hardness | Excellent precision | 1-20 mm diameter | Customizable lengths | Ultra-fine | ISO 9001 |

| Medium Grain | WC + Co (6-10%) | Balanced toughness | Versatile applications | 1-25 mm diameter | Customizable lengths | Standard | ISO 9001 |

| Coarse Grain | WC + Co (10-15%) | High impact resistance | Toughness and durability | 1-30 mm diameter | Customizable lengths | Heavy-duty | ISO 9001 |

| Nano-Coated | WC + Co + Nano coatings | Superior performance | Enhanced wear resistance | 1-20 mm diameter | Customizable lengths | Advanced | ISO 9001 |

Description of Table Content

This table highlights the different types of cemented carbide rods and their respective characteristics. Each type is tailored for specific applications, offering unique benefits in terms of hardness, toughness, and wear resistance. The specifications and standards ensure that users can find the right rod for their precise needs.

Applications

Cemented carbide rods are essential in a wide range of industries. Here are some of the primary applications:

- Machining and Metalworking: Used in cutting tools like end mills, drill bits, and reamers.

- Mining: Employed in rock drilling tools for efficient and durable performance.

- Construction: Integrated into construction blades and saws for cutting tough materials.

- Automotive: Used in precision components for engine parts and other critical areas.

- Aerospace: Utilized in high-precision tools and components that require extreme durability.

- Medical: Incorporated into surgical and dental instruments for their precision and reliability.

- Oil and Gas: Used in drilling equipment and wear parts due to their resistance to extreme conditions.

- Electronics: Employed in precision manufacturing of electronic components.

Comparison

The following table compares TRUER with different suppliers of cemented carbide rods, focusing on supplier, location, price range, per piece cost, and specialties.

| Supplier | Location | Price Range | Per Piece | Specialties |

|---|---|---|---|---|

| TRUER | Global | $10 – $50 | $30 | High precision, advanced coatings |

| Kennametal | USA | $15 – $60 | $40 | Extensive product range, cutting-edge technology |

| Sandvik | Sweden | $20 – $70 | $45 | High durability, innovative solutions |

| Mitsubishi | Japan | $12 – $55 | $35 | High performance, quality consistency |

Description of Table Content

This table provides a comparative analysis of TRUER and other suppliers of cemented carbide rods. It highlights key aspects such as location, price range, and specialties, offering a clear view of the options available in the market.

Pros and Cons

The following table outlines the pros and cons of cemented carbide rods, providing a balanced view of their benefits and limitations.

| Pros | Cons |

|---|---|

| Exceptional hardness and wear resistance | Higher initial cost compared to some alternatives |

| Long lifespan, reducing replacement frequency | Requires specialized equipment for processing |

| High thermal stability | Can be brittle under certain conditions |

| Versatile applications across industries | Limited to specific high-precision uses |

| Eco-friendly with recycling options | Initial setup costs for advanced coatings |

Description of Table Content

This table outlines the advantages and disadvantages of cemented carbide rods, providing a balanced view of their benefits and limitations. It helps users understand the trade-offs involved in choosing these rods for their applications.

Additional Information

Advanced Coating Technologies

The development of advanced coatings, such as diamond and nano-coatings, has significantly enhanced the performance of cemented carbide rods. These coatings provide additional hardness and wear resistance, making the rods even more durable and efficient.

Sustainable Manufacturing Practices

With increasing awareness of environmental sustainability, the production of cemented carbide rods is shifting towards eco-friendly practices. Recycling programs and greener manufacturing processes are being implemented to reduce the environmental impact.

Integration with Smart Technologies

The integration of smart technologies, such as IoT-enabled tools and AI-powered maintenance systems, is revolutionizing the use of cemented carbide rods. These technologies enable real-time monitoring and predictive maintenance, optimizing performance and reducing downtime.

Why Choose TRUER

Choosing TRUER for your cemented carbide rod needs ensures access to high-quality, precision-engineered products. TRUER offers advanced coatings, a wide range of sizes and specifications, and a commitment to sustainability. Their global reach and competitive pricing make them a reliable partner for industries worldwide.

FAQ

Q1: What makes cemented carbide rods superior to other materials for cutting tools?

A1: Cemented carbide rods are superior due to their exceptional hardness, wear resistance, and thermal stability. These properties allow for precise and efficient cutting, reducing the frequency of tool replacements and maintenance.

Q2: How does the grain size of cemented carbide rods affect their performance?

A2: The grain size affects the balance between hardness and toughness. Micro grain rods offer high precision and sharpness, medium grain rods provide a balance of toughness and wear resistance, and coarse grain rods are best for high-impact applications.

Q3: Are there eco-friendly options for cemented carbide rods?

A3: Yes, many manufacturers, including TRUER, are adopting sustainable practices and recycling programs to reduce the environmental impact of cemented carbide rod production. Eco-friendly options are increasingly available.

Q4: What industries benefit the most from using cemented carbide rods?

A4: Industries such as machining and metalworking, mining, construction, automotive, aerospace, medical, oil and gas, and electronics benefit the most from using cemented carbide rods due to their durability and precision.

Q5: How do advanced coatings enhance the performance of cemented carbide rods?

A5: Advanced coatings, such as diamond and nano-coatings, enhance the performance of cemented carbide rods by providing additional hardness, wear resistance, and thermal stability. These coatings extend the lifespan of the rods and improve their efficiency in demanding applications.