What is Carbide Tool Sharpening?

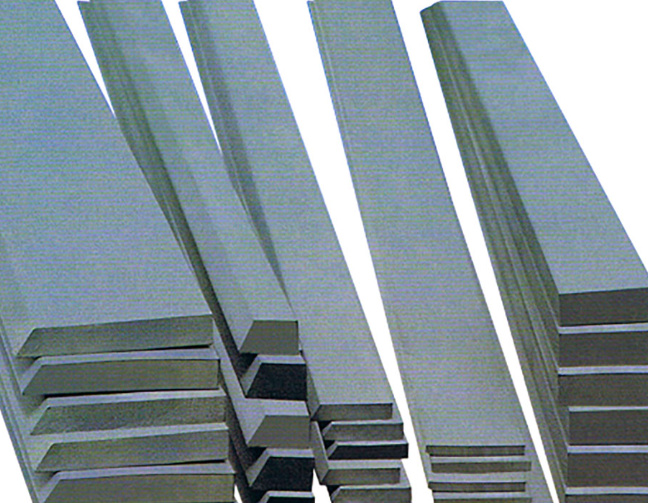

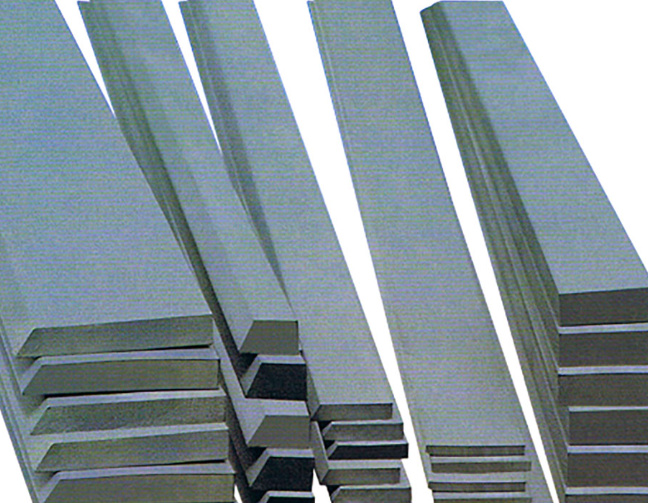

Carbide tool sharpening is the process of restoring the cutting edges of tools made from tungsten carbide, a material renowned for its incredible hardness and resistance to wear. Think of it as giving your tools a much-needed makeover to extend their lifespan and maintain peak performance. Carbide tools are commonly used in industries such as machining, woodworking, and construction due to their ability to handle tough materials. Over time, even the toughest tools get dull—and that’s where sharpening comes in.

Imagine using a dull knife to slice through a loaf of bread—frustrating, right? The same principle applies to carbide tools. Sharpening them ensures you’re cutting through materials with precision and efficiency.

The Importance and Wide Application of Carbide Tool Sharpening

Why bother sharpening carbide tools? The answer lies in their performance and durability. Sharp tools:

- Enhance Productivity: Sharp carbide tools cut faster and cleaner, saving you time and effort.

- Reduce Material Waste: A sharp edge ensures precise cuts, reducing errors and material loss.

- Extend Tool Life: Regular sharpening prevents premature wear and tear, saving you money in the long run.

Carbide tools are used in diverse industries, including aerospace, automotive, and metalworking. For example, machinists rely on carbide-tipped drills and end mills to shape metal parts, while woodworkers depend on carbide saw blades for clean, efficient cuts. Without proper sharpening, these tools can quickly lose their edge—literally and figuratively.

The Necessity of Introducing Grinding in Carbide Tool Sharpening

When it comes to sharpening carbide tools, grinding is the go-to method. Why? Carbide is incredibly hard and requires specialized equipment to achieve the perfect edge. Grinding removes microscopic layers of material to restore the tool’s cutting surface.

But why introduce grinding into your workflow? Here are a few reasons:

- Precision: Grinding provides a fine finish and maintains the tool’s geometry.

- Efficiency: Modern grinding machines make quick work of even the toughest carbide tools.

- Versatility: Grinding accommodates a wide range of tool shapes and sizes.

Skipping grinding is like skipping the sharpening stone when honing a blade—you might get results, but they’ll be subpar.

Why is Sharpening Necessary?

| Reason | Explanation |

|---|---|

| Improved Performance | Sharp tools cut cleaner and faster, enhancing overall efficiency. |

| Cost Savings | Regular sharpening reduces the need for frequent tool replacements. |

| Safety | Dull tools require more force, increasing the risk of accidents and injuries. |

| Material Quality | A sharp tool ensures smoother finishes, reducing rework and defects. |

Methods of Carbide Tool Sharpening

| Method | Description |

|---|---|

| Diamond Grinding Wheels | Ideal for carbide tools due to their hardness and precision. |

| Electric Grinders | Suitable for large-scale operations requiring speed and accuracy. |

| Hand-Held Grinders | Useful for small tools or on-the-go sharpening. |

| Professional Services | Ensures expert precision and optimal results for high-value tools. |

Common Challenges and How to Overcome Them

Sharpening carbide tools isn’t without its hurdles. Here are some common challenges and tips to tackle them:

- Heat Generation: Grinding generates heat, which can damage the tool’s structure. To counter this, use coolant fluids or take frequent breaks during the process.

- Tool Chipping: Carbide is brittle and can chip if mishandled. Opt for diamond grinding wheels and handle tools with care.

- Maintaining Geometry: Precision is key in sharpening. Invest in high-quality grinders or consult a professional service.

Think of it like baking—precision and the right tools make all the difference between success and failure.

Benefits of Professional Sharpening Services

Why trust the pros? Here are some compelling reasons:

- Expertise: Professionals have the experience and equipment to deliver precise results.

- Time Savings: Outsourcing sharpening lets you focus on your core tasks.

- Consistent Quality: Professionals ensure your tools perform at their best every time.

Imagine hiring a personal trainer for your tools—you’re guaranteed better performance and longevity.

How to Choose a Carbide Tool Sharpening Service?

Choosing the right service provider can feel overwhelming. Here’s a checklist to guide you:

- Reputation: Check reviews and ask for recommendations.

- Experience: Look for providers with a proven track record in sharpening carbide tools.

- Equipment: Ensure they use modern, high-quality grinding machines.

- Turnaround Time: Ask about lead times to minimize downtime.

- Cost: Compare prices, but don’t compromise on quality.

Selecting the right service is like picking the perfect restaurant—you want great reviews, skilled chefs, and a satisfying experience.

FAQs

| Question | Answer |

|---|---|

| How often should I sharpen my tools? | It depends on usage, but inspect tools regularly and sharpen as needed. |

| Can I sharpen carbide tools at home? | Yes, with the right equipment and skills, but professional services are recommended. |

| What are the signs of a dull tool? | Increased cutting resistance, rough finishes, and excessive heat. |

| Is sharpening cost-effective? | Absolutely! It extends tool life and reduces replacement costs. |

| What tools require sharpening? | Common examples include drill bits, saw blades, and milling cutters. |