In the world of precision machining, carbide threading inserts are nothing short of game-changers. These small yet powerful tools are the backbone of industries ranging from automotive to aerospace, ensuring that threads on bolts, nuts, and other fasteners are made to perfection. But where do these inserts come from? How do you choose the right manufacturer? What makes one type of carbide threading insert better than another? Let’s explore these questions and more.

Overview of Carbide Threading Inserts

Carbide threading inserts are crucial components used in various machining processes. These inserts are typically made from a combination of tungsten carbide and other metal powders, which provide them with exceptional hardness, wear resistance, and thermal stability. The choice of carbide threading inserts can significantly impact the efficiency, quality, and cost-effectiveness of your machining operations.

But not all carbide threading inserts are created equal. The manufacturing process, material composition, and precision engineering play critical roles in determining the performance and lifespan of these inserts. That’s why selecting the right manufacturer is as important as choosing the right product.

Types of Carbide Threading Inserts

There are several types of carbide threading inserts available, each designed for specific applications. Below is a detailed breakdown of the various types you might encounter:

| Insert Type | Description |

|---|---|

| ISO Metric Threading | Standard threading for general applications, most commonly used worldwide. |

| Unified National Threading (UN) | Common in North America, designed for compatibility with UN standards. |

| Acme Threading | Designed for power screws, these inserts feature a trapezoidal thread profile. |

| Buttress Threading | Ideal for applications with high axial loads, such as in construction machinery. |

| Whitworth Threading | Used in the UK, features a 55° thread angle, common in older applications. |

| Trapezoidal Threading | Similar to Acme, but with a higher thread angle, often used in heavy-duty applications. |

| Pipe Threading (NPT) | Used for creating tapered threads on pipes, ensuring a tight seal. |

| Round Threading | Designed for high-speed machining, featuring a rounded profile for reduced wear. |

| V-Threading | Common in precision applications, known for its versatility and strength. |

| Double-Start Threading | Features two threads running in parallel, allowing for faster assembly. |

Application of Carbide Threading Inserts

Each type of carbide threading insert is optimized for specific applications. Here’s a closer look at where and how these inserts are used:

| Application Area | Description |

|---|---|

| Automotive Industry | Used for manufacturing engine components, ensuring precise threading for bolts and nuts. |

| Aerospace Industry | Critical for producing high-strength fasteners that can withstand extreme conditions. |

| Oil & Gas Industry | Vital for creating durable threads on pipes and drilling equipment that must endure harsh environments. |

| Construction Machinery | Employed in the production of heavy-duty machinery components, requiring high load-bearing threads. |

| Medical Devices | Precision threading in surgical instruments and implants for reliable performance. |

| Electronics | Used in the assembly of small, intricate parts where precision threading is essential. |

| Heavy Equipment | Needed for the manufacturing of large-scale machinery with robust threading requirements. |

| Marine Industry | Essential for creating corrosion-resistant threads in marine equipment and fasteners. |

Material Properties of Carbide Threading Inserts

The performance of carbide threading inserts depends heavily on their material properties. Here’s an overview of the key properties that make carbide inserts the preferred choice in many industries:

| Material Property | Description |

|---|---|

| Hardness | Carbide inserts are extremely hard, making them resistant to wear and deformation. |

| Toughness | While hard, carbide inserts are also tough, allowing them to absorb impacts without fracturing. |

| Thermal Stability | Carbide materials can withstand high temperatures, which is crucial during high-speed machining. |

| Wear Resistance | The wear resistance of carbide is unmatched, making these inserts ideal for long production runs. |

| Corrosion Resistance | Carbide inserts resist corrosion, extending their lifespan in challenging environments. |

Composition and Characteristics of Carbide Threading Inserts

The composition of carbide threading inserts varies depending on their intended application. Below is a table highlighting different compositions and their respective characteristics:

| Carbide Composition | Characteristics |

|---|---|

| WC-Co (Tungsten Carbide-Cobalt) | High hardness and strength, excellent wear resistance, common in general machining. |

| WC-TiC-Co (Tungsten Carbide-Titanium Carbide-Cobalt) | Improved wear resistance and thermal stability, suitable for high-speed applications. |

| WC-TaC-Co (Tungsten Carbide-Tantalum Carbide-Cobalt) | Enhanced toughness, ideal for heavy-duty applications. |

| WC-Ni (Tungsten Carbide-Nickel) | Corrosion-resistant, used in marine and chemical industries. |

| WC-TiN-Co (Tungsten Carbide-Titanium Nitride-Cobalt) | High-temperature stability, excellent for cutting tools. |

| WC-VC-Co (Tungsten Carbide-Vanadium Carbide-Cobalt) | Superior wear resistance, used in abrasive environments. |

| WC-ZrC-Co (Tungsten Carbide-Zirconium Carbide-Cobalt) | Provides a balance between toughness and wear resistance. |

| WC-CrC-Co (Tungsten Carbide-Chromium Carbide-Cobalt) | Good corrosion and oxidation resistance, suitable for high-temperature applications. |

| WC-NbC-Co (Tungsten Carbide-Niobium Carbide-Cobalt) | High hardness with moderate toughness, used in specialized applications. |

| WC-TaN-Co (Tungsten Carbide-Tantalum Nitride-Cobalt) | Exceptional toughness and thermal stability, perfect for demanding environments. |

Hardness, Strength, and Wear Resistance of Carbide Threading Inserts

Understanding the hardness, strength, and wear resistance of carbide threading inserts is essential for selecting the right insert for your application:

| Property | Description |

|---|---|

| Hardness | Measured on the Rockwell C scale (HRC), typically ranges from 75 to 90 HRC. |

| Compressive Strength | High compressive strength, often exceeding 4000 MPa, allows carbide inserts to withstand extreme pressure. |

| Wear Resistance | Exceptional wear resistance ensures a long lifespan, even in abrasive conditions. |

| Fracture Toughness | Balances hardness and toughness to prevent chipping or cracking during use. |

| Thermal Conductivity | High thermal conductivity helps dissipate heat, prolonging the life of the insert. |

| Corrosion Resistance | Varies based on composition, but generally high, especially with Ni and CrC-based carbides. |

Specifications, Sizes, Shapes, and Standards

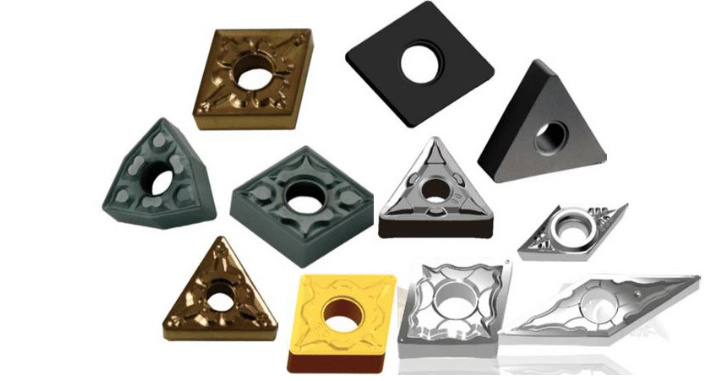

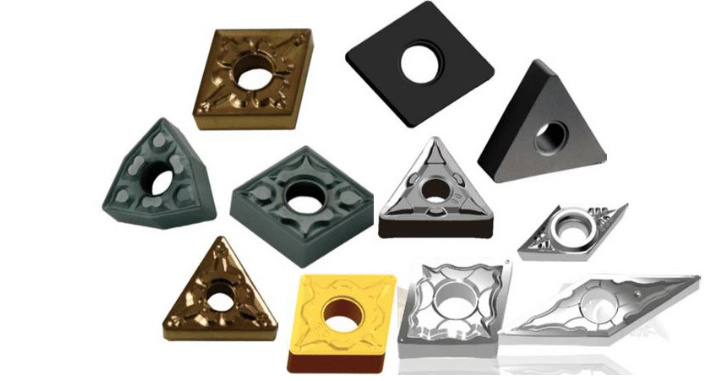

Carbide threading inserts come in a variety of specifications, sizes, shapes, and standards. Below is an overview of these variations:

| Specification | Description |

|---|---|

| ISO Standards | International standards ensure compatibility and interchangeability. |

| ANSI Standards | Common in the United States, ensuring adherence to specific measurements and tolerances. |

| JIS Standards | Japanese standards, often used in Asian markets, focusing on precision and quality. |

| Size Range | Inserts are available in sizes ranging from small (for delicate work) to large (for heavy-duty applications). |

| Shape Variations | Common shapes include triangular, square, diamond, and round, each suited for different threading tasks. |

| Coatings | Inserts may come with coatings such as TiN, TiCN, or Al2O3 to enhance performance and longevity. |

| Cutting Edge | Inserts may feature different cutting edge geometries, such as sharp, rounded, or chamfered, to suit specific materials and operations. |

Suppliers and Pricing Details

Choosing a supplier is as important as selecting the right product. Here’s a comparison of popular suppliers, their offerings, and pricing details:

| Supplier | Product Range | Pricing | Reputation |

|---|---|---|---|

| Kennametal | Offers a wide range of carbide threading inserts with a focus on high-performance materials. | Mid to high-range pricing | Known for innovation and quality. |

| Sandvik Coromant | Specializes in precision-engineered inserts for demanding applications. | High-end pricing | Trusted in aerospace and automotive industries. |

| Mitsubishi Materials | Provides a broad spectrum of threading inserts with competitive pricing. | Mid-range pricing | Renowned for durability and reliability. |

| ISCAR | Known for offering innovative designs and advanced coatings. | High-end pricing | Preferred in high-tech manufacturing. |

| Seco Tools | Features a variety of threading inserts with a focus on versatility and performance. | Mid to high-range pricing | Highly regarded for customer support and product variety. |

| Kyocera | Offers cost-effective solutions with reliable performance. | Low to mid-range pricing | Recognized for affordability and availability. |

| Tungaloy | Provides high-quality inserts with excellent wear resistance. | Mid-range pricing | Known for consistency and longevity. |

| Walter Tools | Focuses on precision and high-performance threading solutions. | High-end pricing | Valued in precision industries like medical and electronics. |

| Sumitomo Electric | Offers durable and high-performance threading inserts. | Mid to high-range pricing | Reputed for innovation in materials and coatings. |

| YG-1 | Delivers cost-effective carbide threading inserts suitable for general-purpose machining. | Low to mid-range pricing | Known for budget-friendly options with decent performance. |

Selecting the Right Carbide Threading Inserts Manufacturers

Choosing the right manufacturer is crucial for ensuring the quality and performance of your carbide threading inserts. Here’s a guide to help you make an informed decision:

| Selection Criteria | Considerations |

|---|---|

| Product Range | Does the manufacturer offer a variety of inserts suitable for different applications? |

| Quality Standards | Are the products ISO, ANSI, or JIS certified? Does the manufacturer adhere to strict quality control processes? |

| Innovation | Does the manufacturer invest in R&D to continuously improve their products? |

| Pricing | Are the products priced competitively without compromising on quality? |

| Customer Support | Does the manufacturer provide excellent customer service and technical support? |

| Lead Time | Can the manufacturer deliver products within the required timeframe? |

| Reputation | What is the manufacturer’s reputation in the industry? Are they known for reliability and quality? |

| Sustainability | Does the manufacturer follow environmentally sustainable practices? |

Advantages and Limitations of Carbide Threading Inserts

When selecting carbide threading inserts, it’s important to weigh their advantages and limitations:

| Advantages | Limitations |

|---|---|

| High Durability | Carbide inserts last longer than other materials, reducing the need for frequent replacements. |

| Superior Performance | These inserts can handle high-speed machining and heavy loads, making them ideal for demanding applications. |

| Consistency | Carbide threading inserts provide consistent results, ensuring high-quality threads every time. |

| Versatility | Available in various shapes, sizes, and compositions to suit a wide range of applications. |

| Cost-Effective | Though initially more expensive, their longevity and performance make them cost-effective in the long run. |

| Initial Cost | Carbide inserts can be more expensive upfront compared to other materials. |

| Specialized Equipment | Requires specialized machinery and expertise to get the best results from carbide inserts. |

| Brittleness | Despite their toughness, carbide inserts can be brittle and may fracture under improper use. |

FAQs

To address common questions and concerns, here’s an FAQ section that can help guide your decisions:

| Question | Answer |

|---|---|

| What are carbide threading inserts? | Carbide threading inserts are cutting tools made from tungsten carbide, used in precision machining to create threads. |

| Why choose carbide over other materials? | Carbide offers superior hardness, wear resistance, and thermal stability compared to materials like steel. |

| How do I select the right insert? | Consider the application, material being machined, and the specifications required. Consult with manufacturers for recommendations. |

| Can carbide inserts be reused? | Yes, carbide inserts can be resharpened and reused, though they may eventually wear out. |

| What is the lifespan of a carbide insert? | The lifespan varies depending on the application, but carbide inserts typically last longer than other materials. |

| Are coated inserts better? | Coatings like TiN or Al2O3 can enhance performance, especially in high-speed or high-temperature applications. |

| How do I maintain carbide inserts? | Proper maintenance includes regular inspection, correct handling, and appropriate storage to avoid damage. |

| What are the alternatives to carbide? | Alternatives include high-speed steel (HSS) and ceramic inserts, though they may not offer the same performance as carbide. |

| Where can I buy carbide threading inserts? | You can purchase carbide threading inserts from reputable suppliers like Kennametal, Sandvik Coromant, and others listed above. |

| Is there a difference between brands? | Yes, different manufacturers may offer varying quality, durability, and pricing, so it’s important to choose based on your specific needs. |