Introduction

Carbide strips are indispensable in various industrial applications due to their exceptional hardness, wear resistance, and durability. However, their performance and longevity are not solely dependent on the material properties but also significantly influenced by their geometry and design. In this detailed blog, we will delve into how different geometries and design features of carbide strips impact their performance and durability. By understanding these factors, you can make informed decisions to optimize the use of carbide strips in your operations.

The Importance of Geometry in Carbide Strips

1. Edge Geometry

Properties:

- Sharpness: Determines the cutting efficiency.

- Strength: Influences resistance to chipping and breakage.

- Wear Resistance: Affects the strip’s lifespan.

Impact: The edge geometry of a carbide strip is crucial for applications involving cutting, scraping, or shaping. A sharper edge provides cleaner cuts and higher precision, which is essential for tasks like machining and woodworking. However, sharper edges are more prone to chipping and may wear out faster. Conversely, a more rounded edge offers greater durability and strength, making it suitable for heavy-duty applications where impact resistance is critical.

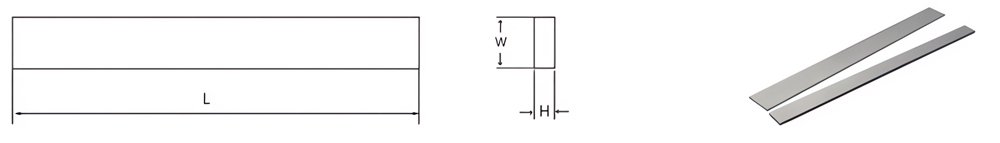

2. Thickness and Width

Properties:

- Rigidity: Thicker strips provide more support and stability.

- Flexibility: Thinner strips can adapt to more intricate shapes and surfaces.

- Heat Dissipation: Wider strips can dissipate heat more effectively.

Impact: The thickness and width of a carbide strip influence its rigidity and flexibility. Thicker and wider strips are more rigid and capable of withstanding higher loads without deforming, making them ideal for heavy-duty applications. Thinner strips, on the other hand, offer more flexibility, which is beneficial for applications requiring intricate shapes and fine details. Additionally, wider strips have better heat dissipation, reducing the risk of thermal damage during high-speed operations.

3. Length

Properties:

- Coverage: Longer strips cover more area, reducing the need for frequent replacements.

- Support: Longer strips can provide better support for large components.

Impact: The length of a carbide strip determines its coverage and support capabilities. Longer strips can cover a larger area, which is advantageous in applications like milling or planing where extensive surface contact is required. However, longer strips may also be more challenging to handle and install, especially in confined spaces.

4. Surface Finish

Properties:

- Smoothness: Affects friction and wear rate.

- Coating Compatibility: Determines how well the strip can hold protective coatings.

Impact: The surface finish of a carbide strip plays a significant role in its performance. A smoother surface reduces friction, which can enhance cutting efficiency and decrease wear. Additionally, a well-finished surface can better adhere to protective coatings, further extending the strip’s lifespan by enhancing its resistance to wear and corrosion.

Design Features and Their Effects

1. Chamfered Edges

Properties:

- Debris Clearance: Facilitates the removal of chips and debris.

- Damage Prevention: Reduces the risk of edge chipping.

Impact: Chamfered edges on carbide strips are designed to improve performance by facilitating debris clearance and reducing the risk of edge damage. This design feature is particularly beneficial in applications like milling and drilling, where efficient chip removal is critical to prevent clogging and ensure smooth operation.

2. Reinforced Corners

Properties:

- Strength: Increases resistance to breakage at vulnerable points.

- Durability: Enhances overall lifespan.

Impact: Reinforced corners provide additional strength to the most vulnerable parts of a carbide strip. This design is crucial for applications involving high impact or stress, such as in mining or heavy machinery, where the corners are prone to breaking or chipping.

3. Grooved or Serrated Edges

Properties:

- Grip: Improves the strip’s ability to grip materials.

- Cutting Efficiency: Enhances the strip’s cutting ability.

Impact: Grooved or serrated edges can significantly enhance the performance of carbide strips in specific applications. These design features improve the strip’s grip on materials, making them ideal for tasks like sawing or cutting abrasive materials. The serrations provide additional cutting points, increasing efficiency and reducing the force required for cutting.

4. Tapered Designs

Properties:

- Precision: Allows for more precise control and cutting.

- Flexibility: Offers better adaptability to various shapes and angles.

Impact: Tapered designs in carbide strips provide better control and precision, which is essential for detailed work and intricate cutting tasks. This design allows the strip to adapt more easily to different shapes and angles, making it versatile for a wide range of applications, from fine woodworking to precision machining.

5. Multi-Layered Structures

Properties:

- Strength: Enhances overall structural integrity.

- Wear Resistance: Provides multiple layers of wear protection.

Impact: Multi-layered structures in carbide strips can offer superior performance and durability. Each layer can be engineered to provide specific benefits, such as increased strength, wear resistance, or thermal stability. This design is particularly advantageous in high-wear applications, where a single-layer strip might wear out too quickly.

Comparative Analysis of Design Features

To better understand how different design features impact the performance and durability of carbide strips, let’s compare their key properties in a tabular format.

| Design Feature | Key Properties | Primary Benefits | Typical Applications |

|---|---|---|---|

| Chamfered Edges | Debris Clearance, Damage Prevention | Reduces edge chipping, facilitates chip removal | Milling, drilling |

| Reinforced Corners | Strength, Durability | Increases resistance to breakage, enhances lifespan | Mining, heavy machinery |

| Grooved/Serrated Edges | Grip, Cutting Efficiency | Improves grip, enhances cutting ability | Sawing, cutting abrasive materials |

| Tapered Designs | Precision, Flexibility | Provides precise control, adapts to various shapes | Fine woodworking, precision machining |

| Multi-Layered Structures | Strength, Wear Resistance | Enhances structural integrity, provides wear protection | High-wear applications, heavy-duty operations |

Innovations in Carbide Strip Design

The field of carbide strip design is continually evolving, with new innovations aimed at enhancing performance and durability. Some recent advancements include:

- Advanced Coating Technologies: Development of coatings such as diamond-like carbon (DLC) and titanium nitride (TiN) to improve wear resistance and reduce friction.

- Hybrid Designs: Combining different geometries and design features to create carbide strips with tailored properties for specific applications.

- Smart Materials: Integration of sensors and smart materials to monitor the condition and performance of carbide strips in real-time, enabling predictive maintenance.

Maintenance and Care for Carbide Strips

Proper maintenance and care are essential to ensure the longevity and optimal performance of carbide strips. Here are some tips:

- Regular Inspection: Periodically inspect carbide strips for signs of wear, damage, or chipping. Early detection can prevent further deterioration.

- Cleaning: Keep carbide strips clean to prevent the buildup of debris and contaminants that could affect their performance.

- Sharpening: Regularly sharpen cutting edges to maintain precision and efficiency. Use appropriate sharpening tools and techniques to avoid damaging the carbide.

- Proper Storage: Store carbide strips in a dry, cool place to prevent corrosion and physical damage. Use protective covers or cases if available.

FAQ

Q1: How does the edge geometry of a carbide strip affect its performance?

A1: The edge geometry of a carbide strip directly impacts its cutting efficiency, durability, and resistance to chipping. Sharper edges provide cleaner cuts and higher precision but are more prone to chipping. Rounded edges offer greater durability and strength, making them suitable for heavy-duty applications.

Q2: Why is the thickness and width of a carbide strip important?

A2: The thickness and width determine the strip’s rigidity, flexibility, and heat dissipation. Thicker and wider strips are more rigid and can withstand higher loads, ideal for heavy-duty tasks. Thinner strips offer more flexibility for intricate shapes, and wider strips dissipate heat more effectively, reducing the risk of thermal damage.

Q3: What benefits do chamfered edges provide in carbide strips?

A3: Chamfered edges facilitate debris clearance and reduce the risk of edge chipping. This design feature is beneficial in applications like milling and drilling, where efficient chip removal is critical to prevent clogging and ensure smooth operation.

Q4: How do multi-layered structures enhance the performance of carbide strips?

A4: Multi-layered structures enhance the overall structural integrity and provide multiple layers of wear protection. Each layer can be engineered to offer specific benefits such as increased strength, wear resistance, or thermal stability, making them ideal for high-wear and heavy-duty applications.

Q5: What are some recent innovations in carbide strip design?

A5: Recent innovations include advanced coating technologies like diamond-like carbon (DLC) and titanium nitride (TiN) to improve wear resistance, hybrid designs combining different geometries and features, and the integration of smart materials and sensors to monitor performance in real-time for predictive maintenance.

Want to buy Carbide Strips at a good price? Please click here.