Overview

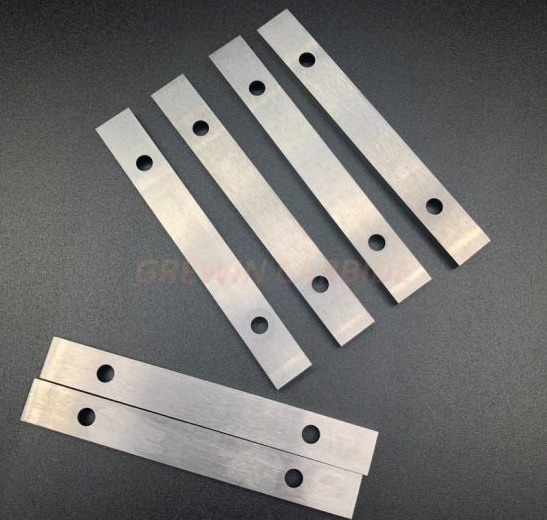

When it comes to precision tooling and high-performance machinery, carbide strips are indispensable. These small but mighty components offer remarkable hardness, strength, and wear resistance, making them ideal for a wide range of industrial applications. If you’re delving into the world of carbide strips, you’ve likely come across a plethora of options, each with its own set of specifications and characteristics. So, how do you navigate this complex landscape? This guide will walk you through everything you need to know about carbide strips and how to choose the right factory for your needs.

Understanding Carbide Strips

Carbide strips are fabricated from tungsten carbide, a compound known for its exceptional durability and performance in demanding conditions. These strips are utilized in various industries, from manufacturing to mining, due to their ability to maintain sharpness and resist wear under high-stress environments.

Types of Carbide Strips

To provide a clear picture of the variety of carbide strips available, here’s a detailed table highlighting different types and their key properties:

Carbide Strips Types and Their Applications

| Type | Description | Application |

|---|---|---|

| YG6 | High toughness, good wear resistance | Cutting tools, dies, wear parts |

| YG8 | High strength, moderate toughness | Mining tools, wear-resistant parts |

| YG10X | High hardness, superior wear resistance | Precision cutting tools, metalworking |

| YG15 | Excellent impact resistance, suitable for high-impact applications | Mining, oil drilling, heavy-duty machining |

| YG20 | High strength, good toughness | Mining bits, wear-resistant tools |

| YG25 | Extremely tough, excellent resistance to chipping | Heavy-duty cutting tools, mining applications |

| YG8C | High cobalt content, increased toughness | Rock drilling, mining tools |

| YG13X | Fine grain size, high wear resistance | Precision cutting tools, dies |

| YG6X | Ultra-fine grain size, superior hardness | High-precision tools, wear parts |

| YG11C | Balanced hardness and toughness, good for general applications | Wear parts, cutting tools |

Applications of Carbide Strips

Carbide strips find their use in a variety of applications due to their robust nature. Here’s a table to highlight where these strips are typically applied:

Applications of Carbide Strips

| Application | Details |

|---|---|

| Metal Cutting | Used in cutting tools for machining metals and alloys |

| Woodworking | Ideal for making tools that cut, shape, and smooth wood surfaces |

| Mining | Applied in mining tools for drilling and excavation |

| Construction | Used in construction tools such as chisels and hammers |

| Oil and Gas | Utilized in drilling equipment for oil and gas extraction |

| Industrial Machinery | Integral to the manufacturing of machinery parts and components |

| Automotive Industry | Used in the production of automotive parts and tooling |

| Aerospace | Employed in the creation of durable, high-precision parts for aerospace applications |

| Defense | Applied in the manufacture of weapons and military equipment |

| Agricultural Tools | Used in tools for plowing, planting, and harvesting |

Material Properties of Carbide Strips

Understanding the material properties of carbide strips is crucial for selecting the right type for your application. Here’s a comprehensive table detailing these properties:

Material Properties of Carbide Strips

| Property | Description |

|---|---|

| Hardness | Measure of how resistant the material is to deformation or penetration |

| Toughness | Ability to absorb energy and deform plastically before fracturing |

| Wear Resistance | Ability to withstand abrasion and erosion |

| Compressive Strength | Capacity to withstand loads tending to reduce size |

| Thermal Conductivity | Ability to conduct heat |

| Density | Mass per unit volume |

| Elastic Modulus | Ratio of stress to strain in elastic deformation |

| Fracture Toughness | Ability to resist crack propagation |

Composition and Characteristics of Carbide Strips

The composition of carbide strips significantly affects their performance. Here’s a detailed look at the composition and key characteristics:

Composition and Characteristics

| Type | Composition | Characteristics |

|---|---|---|

| YG6 | WC 94%, Co 6% | High toughness, good wear resistance |

| YG8 | WC 92%, Co 8% | High strength, moderate toughness |

| YG10X | WC 90%, Co 10% | High hardness, superior wear resistance |

| YG15 | WC 85%, Co 15% | Excellent impact resistance |

| YG20 | WC 80%, Co 20% | High strength, good toughness |

| YG25 | WC 75%, Co 25% | Extremely tough, excellent resistance to chipping |

| YG8C | WC 92%, Co 8% + Additives | Increased toughness due to high cobalt content |

| YG13X | WC 87%, Co 13% | Fine grain size, high wear resistance |

| YG6X | WC 94%, Co 6% | Ultra-fine grain size, superior hardness |

| YG11C | WC 89%, Co 11% | Balanced hardness and toughness |

Hardness, Strength, and Wear Resistance

When comparing carbide strips, it’s essential to consider their hardness, strength, and wear resistance. Here’s how different types stack up:

Comparison of Hardness, Strength, and Wear Resistance

| Type | Hardness (HRA) | Compressive Strength (MPa) | Wear Resistance |

|---|---|---|---|

| YG6 | 89.5 | 2300 | High |

| YG8 | 88 | 2500 | Moderate |

| YG10X | 91.5 | 2200 | Very High |

| YG15 | 87 | 2700 | High |

| YG20 | 86 | 2900 | Moderate |

| YG25 | 85 | 3100 | High |

| YG8C | 88.5 | 2400 | High |

| YG13X | 90 | 2300 | Very High |

| YG6X | 92 | 2200 | Very High |

| YG11C | 89 | 2500 | High |

Specifications, Sizes, Shapes, and Standards

Carbide strips come in various sizes, shapes, and specifications. Here’s a table to help you understand the common standards and sizes available:

Specifications, Sizes, Shapes, and Standards

| Specification | Size (mm) | Shape | Standard |

|---|---|---|---|

| YG6 | 5x5x100, 10x10x100, 20x20x150 | Rectangular, Square | ISO, ASTM, DIN |

| YG8 | 5x5x100, 10x10x100, 20x20x150 | Rectangular, Square | ISO, ASTM, DIN |

| YG10X | 5x5x100, 10x10x100, 20x20x150 | Rectangular, Square | ISO, ASTM, DIN |

| YG15 | 5x5x100, 10x10x100, 20x20x150 | Rectangular, Square | ISO, ASTM, DIN |

| YG20 | 5x5x100, 10x10x100, 20x20x150 | Rectangular, Square | ISO, ASTM, DIN |

| YG25 | 5x5x100, 10x10x100, 20x20x150 | Rectangular, Square | ISO, ASTM, DIN |

| YG8C | 5x5x100, 10x10x100, 20x20x150 | Rectangular, Square | ISO, ASTM, DIN |

| YG13X | 5x5x100, 10x10x100, 20x20x150 | Rectangular, Square | ISO, ASTM, DIN |

| YG6X | 5x5x100, 10x10x100, 20x20x150 | Rectangular, Square | ISO |

Choosing the Right Carbide Strips Factory

Selecting the right factory for carbide strips is crucial for ensuring you get the best quality and value. Here’s a detailed table to guide you through the factors to consider:

How to Choose the Right Carbide Strips Factory

| Criteria | Details | Examples of Key Factors |

|---|---|---|

| Experience | Look for factories with extensive experience in manufacturing carbide strips. | Longevity in the industry, proven track record |

| Quality Control | Ensure the factory has stringent quality control processes to maintain consistency and reliability. | Certifications, quality assurance protocols |

| Technology and Equipment | Advanced technology and modern equipment can greatly impact the quality of carbide strips. | State-of-the-art machinery, automation |

| Material Sourcing | Check if the factory uses high-grade materials for producing carbide strips. | Source of tungsten and cobalt, material standards |

| Customization Options | Determine if the factory offers customization to meet specific needs and applications. | Custom sizes, shapes, and compositions |

| Pricing | Compare pricing among different factories, but be wary of overly cheap options that might compromise quality. | Cost per unit, bulk pricing options |

| Lead Time and Delivery | Assess the factory’s lead times and delivery reliability to ensure timely receipt of your products. | Shipping times, on-time delivery rates |

| Customer Service | Good customer service is vital for addressing any issues or concerns that arise. | Responsiveness, support availability |

| Reputation and Reviews | Research the factory’s reputation and read reviews from other customers to gauge their reliability. | Customer testimonials, industry reputation |

Comparing Advantages and Limitations of Different Carbide Strips

To help you make an informed decision, here’s a comparison of various carbide strips based on their advantages and limitations:

Comparison of Carbide Strips

| Type | Advantages | Limitations |

|---|---|---|

| YG6 | High toughness, versatile application | Lower wear resistance compared to more specialized grades |

| YG8 | Good balance of strength and toughness | May not be ideal for extremely high-wear environments |

| YG10X | Superior hardness, very high wear resistance | Can be more brittle under high-impact conditions |

| YG15 | Excellent impact resistance, good for high-stress applications | Higher cost, may not be necessary for low-impact tasks |

| YG20 | High strength, good overall toughness | Slightly lower wear resistance than YG25 |

| YG25 | Extremely tough, excellent resistance to chipping | More expensive, may be overkill for less demanding applications |

| YG8C | Increased toughness due to high cobalt content | Can be more expensive, not as hard as some other grades |

| YG13X | Very high wear resistance, fine grain size | More specialized, potentially higher cost |

| YG6X | Ultra-fine grain size, very hard | Brittle, may not withstand high-impact applications |

| YG11C | Balanced hardness and toughness, good for general use | May not excel in extreme conditions compared to specialized grades |

Supplier and Pricing Information

When sourcing carbide strips, it’s important to compare different suppliers to get the best deal. Here’s a table outlining potential suppliers and their pricing details:

Suppliers and Pricing Details

| Supplier | Location | Type of Carbide Strips | Pricing (per unit) | Additional Notes |

|---|---|---|---|---|

| Supplier A | USA | YG6, YG8, YG10X | $5 – $10 | Offers bulk discounts |

| Supplier B | China | YG15, YG20 | $3 – $7 | Competitive pricing, varying quality |

| Supplier C | Germany | YG25, YG8C | $8 – $15 | High-quality standards, longer lead time |

| Supplier D | Japan | YG13X, YG6X | $6 – $12 | Customization options available |

| Supplier E | India | YG11C, YG8 | $4 – $9 | Reliable service, good for general needs |

FAQ

Here are some frequently asked questions about carbide strips and their manufacturers:

Frequently Asked Questions

| Question | Answer |

|---|---|

| What are carbide strips used for? | Carbide strips are used in cutting tools, mining tools, and industrial machinery for their durability and resistance to wear. |

| How do I choose the right type of carbide strip? | Consider the application requirements such as hardness, wear resistance, and impact resistance. Match these needs with the specifications of the carbide strips. |

| What factors affect the cost of carbide strips? | Cost factors include material quality, size, customizations, and the quantity purchased. Higher-grade materials and specialized features typically increase the price. |

| Can carbide strips be customized? | Yes, many manufacturers offer customization options for size, shape, and composition to meet specific requirements. |

| How important is the quality control process? | Quality control is crucial to ensure the carbide strips meet performance standards and have consistent quality. Poor quality control can lead to failures and increased costs. |

| What are the benefits of using a well-established factory? | Established factories often have better quality control, reliable delivery, and more experience in producing high-quality carbide strips. |

Conclusion

Navigating the world of carbide strips and choosing the right factory can be daunting, but with the right information, it becomes manageable. From understanding the different types and their applications to evaluating suppliers and their pricing, this guide provides a comprehensive look at what you need to know.

Whether you’re looking for high toughness, superior wear resistance, or specific customizations, knowing the properties, applications, and options available will help you make the best choice for your needs. So, dive in, assess your requirements, and select a factory that meets your criteria for quality, reliability, and cost-effectiveness.