Carbide Sandblasting Machine

Our wet sandblasting machine is a surface treatment equipment for high quality carbide insert manufacturing by using a mixture of abrasive media and water under pressure to realize pre-treatment before coating, post-treatment after coating and edge honing etc.

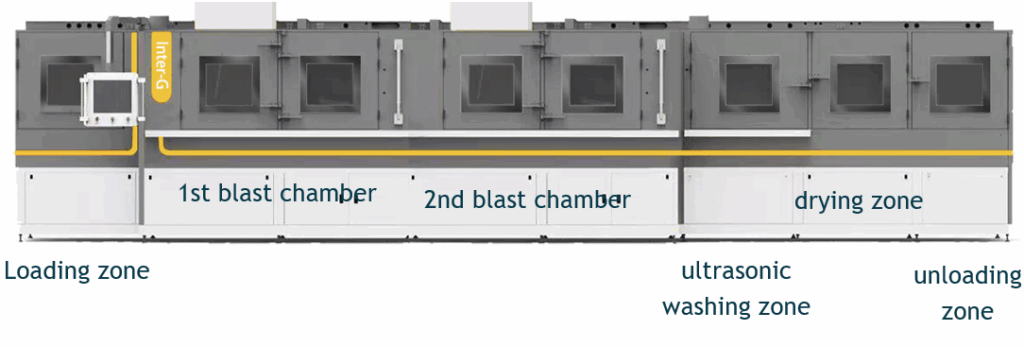

The machine including following units:

- loading unit

- blasting unit

- rinsing unit

- drying unit

- unloading unit

Learn more, please watch this video:

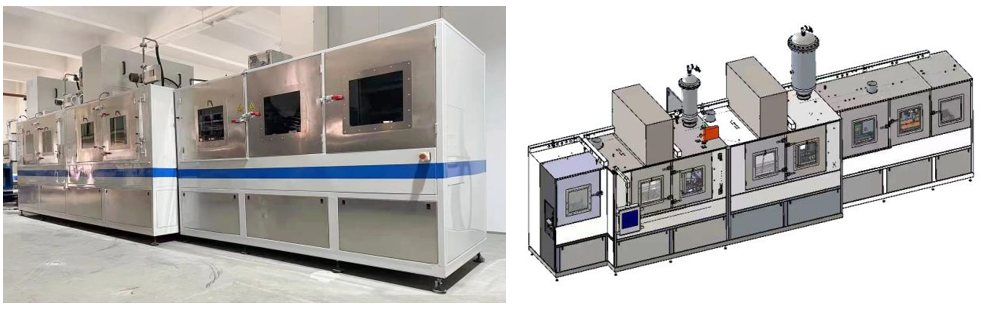

Single-chamber sandblasting machine:

For surface treatment or for edge honing

Double-chamber sandblasting machine:

Surface treatment and edge honing can be performed at the same time.

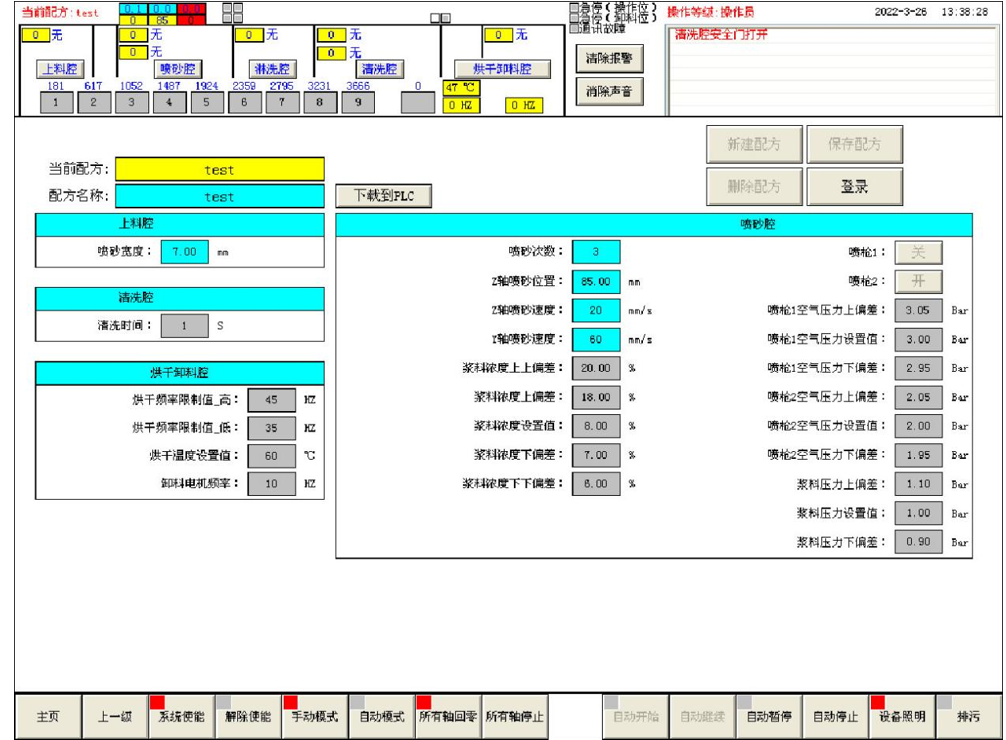

Interface:

- Complete functions to meet different process requirements.

- This interface is used for recipe editing, modifying parameters, downloading recipes, creating new recipes etc.

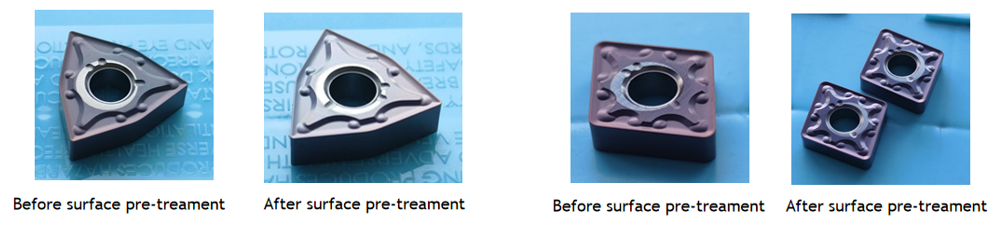

Application:

Surface pre-treament before coating

- Remove residual contaminants and oxidation of carbide insert surface, finish the insert to good surface roughness condition and reduce residual stress. It will greatly enhance coating adhesion and improve insert mechanical properties and fatigue resistance.

- Removes sharp edges and burrs on insert surface, which will improve stability and uniformity of cutting edge.

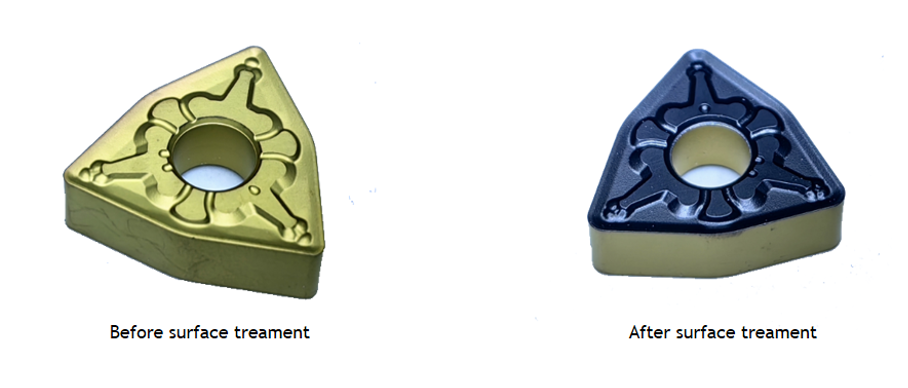

Surface post-treament after coating

- PVD: Remove coating droplet and brighten the insert surface.

- CVD: Brighten the insert surface, remove excess burrs and coating, improve the consistency and uniformity of the insert, so as to improve the cutting performance of the insert

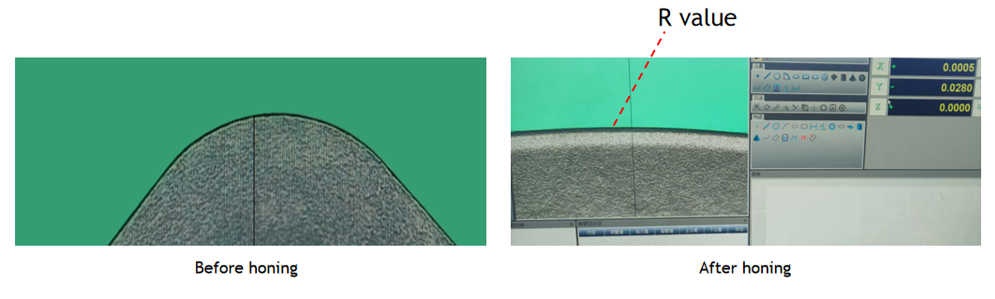

Edge honing

- Remove burrs from the cutting edge and cutting surface.

- Increasing the radius of the edge can greatly reduce the contact length and heat accumulation between the cutting edge and the workpiece material.

- Tool life increased by 30-70%.

Related equipments: