- Solid carbide rod

Solid carbide rod

Solid carbide rods are widely used for creating premium solid carbide tools, such as end mills, drills, reamers, milling cutters, stamping, and measuring tools in different industries. We supply both unground and ground solid carbide rods with top and consistent quality in varied grades. If you would like to learn more about our carbide grades, please click on the link below to browse the grade page.

A comprehensive standard selection of solid carbide rods in various dimensions is available in the below tables, but other sizes, tolerances & configurations also available on request.

Contact us if what you need is not shown here.

Introduction

The 1 Straight Coolant Hole Carbide Rod is a specialized cylindrical tool made of solid carbide material with a straight coolant hole running through its center. It is designed to enhance coolant delivery and improve cutting performance in machining operations. This carbide rod is manufactured with precision to ensure accurate dimensions and a smooth surface finish. The straight coolant hole is carefully aligned, allowing for efficient coolant flow directly to the cutting edge. This facilitates effective cooling, lubrication, and chip evacuation during the machining process.

What is a Solid Carbide Rod?

A solid carbide rod is a cylindrical tool made from a combination of tungsten carbide and a binder metal, typically cobalt. The high percentage of tungsten carbide, known for its extreme hardness, gives the rod exceptional strength and wear resistance.

Composition and Structure

Solid carbide rods are typically composed of 90-94% tungsten carbide and 6-10% cobalt binder. The cobalt binder acts as a matrix, providing toughness and impact resistance to the tool. The rods are manufactured through a powder metallurgy process, followed by sintering to form a solid and homogenous structure.

Hardness

Exceptionally hard with a rating of 90-94 HRA (Rockwell A scale).

Strength

High strength-to-weight ratio, enabling them to withstand heavy loads.

Wear Resistance

Highly resistant to wear and abrasion, maintaining dimensional stability.

Heat Resistance

Excellent heat resistance, making them suitable for high-temperature applications.

Chemical Inertness

Chemically inert, unaffected by acids, alkalis, and corrosive substances.

Low Thermal Expansion

Minimal expansion during temperature variations, ensuring dimensional accuracy.

Electrical Non-Conductivity

Not electrically conductive, providing electrical insulation.

Cutting Performance

Superior cutting performance on a wide range of materials.

Raw Material Selection

High-quality tungsten carbide powder is chosen.

Mixing

The powder is mixed with a binder material to create a homogeneous mixture.

Compacting

The mixture is compacted under high pressure to form a green compact.

Pre-Sintering

The green compact is pre-sintered at a temperature below the final sintering temperature.

Sintering

The pre-sintered compact is heated to a specific temperature for bonding and densification.

Shaping and Grinding

The sintered material is machined into the desired rod shape.

Finishing and Coating

Optional surface treatments are applied to improve performance and corrosion resistance.

Quality Control

Rigorous inspections and tests ensure the rods meet specifications.

Cutting Tools

Solid carbide rods are extensively used in the manufacturing of cutting tools such as end mills, drills, reamers, taps, and inserts. Their exceptional hardness and wear resistance make them ideal for precision machining operations, including milling, drilling, and turning.

Metalworking

Solid carbide rods are employed in metalworking processes such as machining, shaping, and forming. They are used for applications like milling, threading, grooving, and chamfering, providing high precision and long tool life.

Aerospace Industry

Solid carbide rods find extensive use in the aerospace industry for manufacturing critical components and parts. They are used in processes such as milling aircraft parts, drilling holes in aerospace materials, and shaping complex structures.

Automotive Industry

Solid carbide rods are utilized in the automotive industry for various applications. They are used in the production of engine components, brake parts, gears, and transmission components. The high precision and durability of solid carbide tools contribute to efficient and reliable manufacturing processes.

Cutting Tools

Solid carbide rods are extensively used in the manufacturing of cutting tools such as end mills, drills, reamers, taps, and inserts. Their exceptional hardness and wear resistance make them ideal for precision machining operations, including milling, drilling, and turning.

Metalworking

Solid carbide rods are employed in metalworking processes such as machining, shaping, and forming. They are used for applications like milling, threading, grooving, and chamfering, providing high precision and long tool life.

Aerospace Industry

Solid carbide rods find extensive use in the aerospace industry for manufacturing critical components and parts. They are used in processes such as milling aircraft parts, drilling holes in aerospace materials, and shaping complex structures.

Automotive Industry

Solid carbide rods are utilized in the automotive industry for various applications. They are used in the production of engine components, brake parts, gears, and transmission components. The high precision and durability of solid carbide tools contribute to efficient and reliable manufacturing processes.

Solid carbide rods, also known as tungsten carbide rods, are cylindrical bars made from a composite material of tungsten carbide particles and a binder, typically cobalt or nickel. They possess exceptional hardness, strength, and wear resistance.

The main properties of solid carbide rods include high hardness, excellent strength, wear resistance, heat resistance, chemical inertness, low thermal expansion, electrical non-conductivity, and superior cutting performance.

Solid carbide rods find applications in various industries such as manufacturing, aerospace, automotive, metalworking, woodworking, mining, oil and gas, construction, and more.

Solid carbide rods are primarily used in the production of cutting tools like drills, end mills, reamers, and inserts. They are also employed in metalworking operations, woodworking tools, and as wear-resistant components and tooling in various industries.

The manufacturing process of solid carbide rods involves steps like raw material selection, mixing the tungsten carbide powder with a binder, compacting the mixture, pre-sintering, sintering, shaping, grinding, optional finishing and coating, and quality control.

The benefits of using solid carbide rods include extended tool life, increased productivity, high cutting speeds, excellent dimensional accuracy, resistance to wear and abrasion, and the ability to withstand high temperatures.

Yes, different grades and formulations of solid carbide rods can be tailored to meet specific application requirements, allowing customization for factors such as hardness, toughness, and coating options.

Proper maintenance involves regular cleaning, avoiding excessive heat and shock, using appropriate cutting parameters, and periodic inspection for wear or damage. Consult the manufacturer’s guidelines for specific maintenance instructions.

While solid carbide rods may have a higher upfront cost compared to other materials, their long tool life, reduced downtime, and increased productivity often make them cost-effective in the long run.

Yes, safety precautions such as wearing protective gear, handling the rods with care, and following proper machining practices are important to ensure safe usage of solid carbide rods.

Data

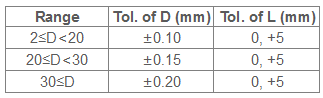

Unground Solid Carbide Rod Description

An unground solid carbide rod is a cylindrical tool made of solid carbide material that has not undergone precision grinding. It is typically composed of a mixture of carbide and metal powders, with tungsten carbide being a common choice. The unground state refers to the rod’s surface not being finely finished or polished.

| Part No. | D/mm | L/mm | Tol. of D/mm | Tol. of L/mm | Grade (click here) |

|---|---|---|---|---|---|

| RSUK00703300 | 0.7 | 330 | +0.40/+0.15 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK00703100 | 0.7 | 310 | +0.40/+0.15 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK00903300 | 0.9 | 330 | +0.40/+0.15 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK00903100 | 0.9 | 310 | +0.40/+0.15 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK01003300 | 1.0 | 330 | +0.40/+0.15 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK01003100 | 1.0 | 310 | +0.40/+0.15 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK01203300 | 1.2 | 330 | +0.40/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK01203100 | 1.2 | 310 | +0.40/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK01503300 | 1.5 | 330 | +0.40/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK01503100 | 1.5 | 310 | +0.40/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK01603300 | 1.6 | 330 | +0.40/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK01603100 | 1.6 | 310 | +0.40/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK01803300 | 1.8 | 330 | +0.40/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK01803100 | 1.8 | 310 | +0.40/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK02003300 | 2.0 | 330 | +0.40/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK02003100 | 2.0 | 310 | +0.40/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK02303300 | 2.3 | 330 | +0.40/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK02303100 | 2.3 | 310 | +0.40/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK02503300 | 2.5 | 330 | +0.40/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK02503100 | 2.5 | 310 | +0.40/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK02803300 | 2.8 | 330 | +0.40/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK02803100 | 2.8 | 310 | +0.40/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK03003300 | 3.0 | 330 | +0.50/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK03003100 | 3.0 | 310 | +0.50/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK03503300 | 3.5 | 330 | +0.50/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK03503100 | 3.5 | 310 | +0.50/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK04003300 | 4.0 | 330 | +0.50/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK04003100 | 4.0 | 310 | +0.50/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK04503300 | 4.5 | 330 | +0.50/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK04503100 | 4.5 | 310 | +0.50/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK05003300 | 5.0 | 330 | +0.50/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK05003100 | 5.0 | 310 | +0.50/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK05503300 | 5.5 | 330 | +0.50/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK05503100 | 5.5 | 310 | +0.50/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK06003300 | 6.0 | 330 | +0.50/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK06003100 | 6.0 | 310 | +0.50/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK06503300 | 6.5 | 330 | +0.50/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK06503100 | 6.5 | 310 | +0.50/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK07003300 | 7.0 | 330 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK07003100 | 7.0 | 310 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK07503300 | 7.5 | 330 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK07503100 | 7.5 | 310 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK08003300 | 8.0 | 330 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK08003100 | 8.0 | 310 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK08503300 | 8.5 | 330 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK08503100 | 8.5 | 310 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK09003300 | 9.0 | 330 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK09003100 | 9.0 | 310 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK09503300 | 9.5 | 330 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK09503100 | 9.5 | 310 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK10003300 | 10.0 | 330 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK10003100 | 10.0 | 310 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK10503300 | 10.5 | 330 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK10503100 | 10.5 | 310 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK11003300 | 11.0 | 330 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK11003100 | 11.0 | 310 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK11503300 | 11.5 | 330 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK11503100 | 11.5 | 310 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK12003300 | 12.0 | 330 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK12003100 | 12.0 | 310 | +0.60/+0.20 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK12503300 | 12.5 | 330 | +0.70/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK12503100 | 12.5 | 310 | +0.70/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK13003300 | 13.0 | 330 | +0.70/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK13003100 | 13.0 | 310 | +0.70/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK14003300 | 14.0 | 330 | +0.70/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK14003100 | 14.0 | 310 | +0.70/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK15003300 | 15.0 | 330 | +0.70/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK15003100 | 15.0 | 310 | +0.70/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK16003300 | 16.0 | 330 | +0.70/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK16003100 | 16.0 | 310 | +0.70/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK17003300 | 17.0 | 330 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK17003100 | 17.0 | 310 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK18003300 | 18.0 | 330 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK18003100 | 18.0 | 310 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK19003300 | 19.0 | 330 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK19003100 | 19.0 | 310 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK20003300 | 20.0 | 330 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK20003100 | 20.0 | 310 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK21003300 | 21.0 | 330 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK21003100 | 21.0 | 310 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK22003300 | 22.0 | 330 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK22003100 | 22.0 | 310 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK23003300 | 23.0 | 330 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK23003100 | 23.0 | 310 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK24003300 | 24.0 | 330 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK24003100 | 24.0 | 310 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK25003300 | 25.0 | 330 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK25003100 | 25.0 | 310 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK26003300 | 26.0 | 330 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK26003100 | 26.0 | 310 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK27003300 | 27.0 | 330 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK27003100 | 27.0 | 310 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK28003300 | 28.0 | 330 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK28003100 | 28.0 | 310 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK29003300 | 29.0 | 330 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK29003100 | 29.0 | 310 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK30003300 | 30.0 | 330 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK30003100 | 30.0 | 310 | +0.80/+0.30 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK31003300 | 31.0 | 330 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK31003100 | 31.0 | 310 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK32003300 | 32.0 | 330 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK32003100 | 32.0 | 310 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK33003300 | 33.0 | 330 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK33003100 | 33.0 | 310 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK34003300 | 34.0 | 330 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK34003100 | 34.0 | 310 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK35003300 | 35.0 | 330 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK35003100 | 35.0 | 310 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK36003300 | 36.0 | 330 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK36003100 | 36.0 | 310 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK37003300 | 37.0 | 330 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK37003100 | 37.0 | 310 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK38003300 | 38.0 | 330 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK38003100 | 38.0 | 310 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK39003300 | 39.0 | 330 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK39003100 | 39.0 | 310 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK40003300 | 40.0 | 330 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK40003100 | 40.0 | 310 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK41003300 | 41.0 | 330 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK41003100 | 41.0 | 310 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK42003300 | 42.0 | 330 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK42003100 | 42.0 | 310 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK43003300 | 43.0 | 330 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK43003100 | 43.0 | 310 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK44003300 | 44.0 | 330 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK44003100 | 44.0 | 310 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK45003300 | 45.0 | 330 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK45003100 | 45.0 | 310 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK46003300 | 46.0 | 330 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK46003100 | 46.0 | 310 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK47003300 | 47.0 | 330 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK47003100 | 47.0 | 310 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK48003300 | 48.0 | 330 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK48003100 | 48.0 | 310 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK49003300 | 49.0 | 330 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK49003100 | 49.0 | 310 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK50003300 | 50.0 | 330 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RSUK50003100 | 50.0 | 310 | +1.20/+0.60 | 0, +5 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| Part No. | D/mm | L/mm | Grade (click here) |

|---|---|---|---|

| RSUJ02303300 | 2.30 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ03303300 | 3.30 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ03303100 | 3.30 | 310 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ04303300 | 4.30 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ04303100 | 4.30 | 310 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ05303300 | 5.30 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ05303100 | 5.30 | 310 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ06303300 | 6.30 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ06303100 | 6.30 | 310 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ07303300 | 7.30 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ08303300 | 8.30 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ08303100 | 8.30 | 310 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ09303300 | 9.30 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ10303300 | 10.30 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ10303100 | 10.30 | 310 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ11303300 | 11.30 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ12403300 | 12.40 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ12403100 | 12.40 | 310 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ13403300 | 13.40 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ14403300 | 14.40 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ14403100 | 14.40 | 310 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ15403300 | 15.40 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ16403300 | 16.40 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ16403100 | 16.40 | 310 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ17403300 | 17.40 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ18403300 | 18.40 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ19403300 | 19.40 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ20453300 | 20.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ20453100 | 20.45 | 310 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ21453300 | 21.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ22453300 | 22.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ23453300 | 23.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ24453300 | 24.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ25453300 | 25.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ26453300 | 26.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ27453300 | 27.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ28453300 | 28.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ29453300 | 29.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ30453300 | 30.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ31453300 | 31.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ32453300 | 32.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ33453300 | 33.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ34453300 | 34.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ35453300 | 35.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ36453300 | 36.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ37453300 | 37.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ38453300 | 38.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ39453300 | 39.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ40453300 | 40.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ41453300 | 41.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSUJ42453300 | 42.45 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

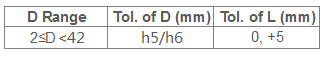

Ground Solid Carbide Rod Description

Ground solid carbide rods are highly precise and durable cutting tools manufactured through precision grinding. They offer exceptional hardness, strength, and wear resistance, making them ideal for high-performance machining operations.

| Part No. | D/mm | L/mm | Grade (click here) |

|---|---|---|---|

| RSGJ02003300 | 2.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ03003100 | 3.00 | 310 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ03003300 | 3.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ04003100 | 4.00 | 310 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ04003300 | 4.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ05003100 | 5.00 | 310 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ05003300 | 5.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ06003100 | 6.00 | 310 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ06003300 | 6.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ07003300 | 7.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ08003100 | 8.00 | 310 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ08003300 | 8.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ09003300 | 9.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ10003100 | 10.00 | 310 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ10003300 | 10.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ11003300 | 11.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ12003100 | 12.00 | 310 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ12003300 | 12.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ13003300 | 13.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ14003100 | 14.00 | 310 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ14003300 | 14.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ15003300 | 15.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ16003100 | 16.00 | 310 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ16003300 | 16.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ17003300 | 17.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ18003300 | 18.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ19003300 | 19.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ20003100 | 20.00 | 310 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ20003300 | 20.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ21003300 | 21.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ22003300 | 22.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ23003300 | 23.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ24003300 | 24.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ25003300 | 25.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ26003300 | 26.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ27003300 | 27.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ28003300 | 28.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ29003300 | 29.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ30003300 | 30.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ31003300 | 31.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ32003300 | 32.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ33003300 | 33.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ34003300 | 34.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ35003300 | 35.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ36003300 | 36.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ37003300 | 37.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ38003300 | 38.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ39003300 | 39.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ40003300 | 40.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ41003300 | 41.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RSGJ42003300 | 42.00 | 330 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

- Contact

Our team is ready to provide support

Truer Carbide is committed to providing efficient solutions to problems. Each team member has the expertise and experience to quickly understand and meet your needs.