- 1 Straight Coolant Hole Carbide Rod

1 Straight Coolant Hole Carbide Rod

Carbide rods with the kind of internal cooling hole can provide much more efficient chip evacuation and deeper hole making capabilities, widely used in drills, reamers, carbide holders. We supply both unground and ground carbide rods with one cooling hole in varied grades. If you would like to learn more about our carbide grades, please click on the link below to browse the grade page.

A comprehensive standard selection of carbide rods with one straight cooling hole in various dimensions is available in the below tables, but other sizes, tolerances & configurations also available on request.

Contact us if what you need is not shown here.

Introduction

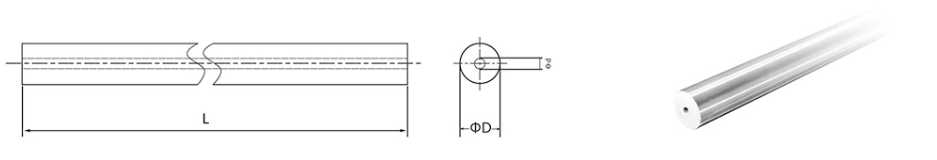

The 1 Straight Coolant Hole Carbide Rod is a specialized cylindrical tool made of solid carbide material with a straight coolant hole running through its center. It is designed to enhance coolant delivery and improve cutting performance in machining operations.

What is a 1 Straight Coolant Hole Carbide Rod?

A solid carbide rod is a cylindrical tool made from a combination of tungsten carbide and a binder metal, typically cobalt. The high percentage of tungsten carbide, known for its extreme hardness, gives the rod exceptional strength and wear resistance.

Composition and Structure

The 1 Straight Coolant Hole Carbide Rod is composed of a solid carbide material that consists primarily of tungsten carbide (WC) particles bonded together with a metallic binder, typically cobalt (Co). This composition provides the rod with excellent hardness, strength, and wear resistance.

The structure of the carbide rod is typically dense and homogeneous, resulting from the sintering process used during its manufacturing. Sintering involves subjecting the carbide powder and binder mixture to high temperatures and pressures, causing the particles to bond together and form a solid structure.

Hardness

The 1 straight coolant hole carbide rod exhibits a high level of hardness, providing excellent resistance to wear and ensuring prolonged tool life.

Strength

These rods possess exceptional strength, enabling them to withstand heavy loads and maintain dimensional stability during machining operations.

Wear Resistance

With their high wear resistance, these carbide rods are designed to endure demanding cutting conditions, making them reliable for long-lasting performance.

Heat Resistance

The carbide rod's excellent heat resistance allows it to withstand the high temperatures generated during machining processes, ensuring stability and durability.

Coolant Flow

The straight coolant hole enables efficient coolant or lubricant flow to the cutting edge, ensuring effective cooling, reducing friction, and improving tool performance.

Chip Evacuation

The coolant hole assists in efficient chip evacuation, preventing chip buildup and enhancing machining efficiency.

Compatibility

1 straight coolant hole carbide rods are compatible with various coolant systems, allowing flexibility in machining setups and applications.

Machining Flexibility

Versatile for use in deep-hole drilling, long-reach milling, and high-speed machining.

Raw Material Selection

High-quality tungsten carbide powder and a suitable binder material, such as cobalt or nickel, are selected.

Mixing

The tungsten carbide powder and binder material are mixed thoroughly to create a homogeneous mixture.

Compacting

Apply high pressure to form a green compact resembling the final rod shape.

Pre-Sintering

Pre-sinter the green compact at a temperature below the final sintering temperature.

Drilling the Coolant Hole

Drill a straight hole through the pre-sintered compact to create the coolant channel.

Sintering

Heat the pre-sintered compact to bond the tungsten carbide particles and form a solid structure.

Shaping and Finishing

Machine the sintered rod to the desired shape and size, ensuring proper coolant hole dimensions.

Quality Control

Conduct inspections, measurements, and tests to ensure the rod meets specifications.

Milling

The carbide rod is used in milling applications for machining surfaces, contours, and pockets in different materials. The straight coolant hole ensures effective coolant flow, enhancing cooling and chip evacuation during the milling process.

Drilling

The carbide rod is employed in drilling operations to create holes in various materials. The straight coolant hole helps deliver coolant directly to the drill bit, reducing heat and prolonging tool life while improving chip evacuation.

Turning

The carbide rod is used in turning operations to shape and create cylindrical components. The straight coolant hole enables efficient coolant delivery to the cutting edge, reducing heat buildup, and improving chip evacuation.

Reaming

The carbide rod is utilized in reaming applications to refine and accurately size existing holes. The straight coolant hole aids in effective coolant delivery, preventing tool overheating and ensuring precise cutting.

Milling

The carbide rod is used in milling applications for machining surfaces, contours, and pockets in different materials. The straight coolant hole ensures effective coolant flow, enhancing cooling and chip evacuation during the milling process.

Drilling

The carbide rod is employed in drilling operations to create holes in various materials. The straight coolant hole helps deliver coolant directly to the drill bit, reducing heat and prolonging tool life while improving chip evacuation.

Turning

The carbide rod is used in turning operations to shape and create cylindrical components. The straight coolant hole enables efficient coolant delivery to the cutting edge, reducing heat buildup, and improving chip evacuation.

Reaming

The carbide rod is utilized in reaming applications to refine and accurately size existing holes. The straight coolant hole aids in effective coolant delivery, preventing tool overheating and ensuring precise cutting.

A 1 straight coolant hole carbide rod refers to a solid carbide rod with a straight hole drilled through its center for coolant or lubricant flow during machining.

The coolant hole enables efficient cooling of the tool and workpiece, improves chip evacuation, reduces friction, and extends tool life.

Yes, the diameter of the coolant hole can be customized based on specific requirements and machining needs.

1 straight coolant hole carbide rods are compatible with various coolant systems, including through-spindle coolant systems, external coolant supplies, and flood coolant systems.

Yes, these rods are versatile and can be used in various machining operations such as drilling, milling, turning, and high-speed machining.

Proper maintenance includes regular cleaning, ensuring coolant flow is unobstructed, and inspecting the coolant hole for any debris or blockages.

While the initial cost may be higher, the extended tool life, improved machining efficiency, and reduced downtime often make them cost-effective in the long run.

Safety precautions include wearing appropriate protective gear, following machining guidelines, and ensuring proper coolant flow without any leaks or hazards.

The presence of a coolant hole does not significantly impact the rigidity or overall performance of the carbide rod when used within recommended parameters.

Coolant hole carbide rods are available from reputable tooling suppliers, manufacturers, and distributors specializing in cutting tools and machining components.

Data

Unground 1 Straight Coolant Hole Carbide Rod Description

An unground 1 Straight Coolant Hole Carbide Rod is a cylindrical tool made of solid carbide material with a straight coolant hole running through its center. Unlike a ground carbide rod, the unground version has not undergone precision grinding, resulting in a rough or unfinished surface. The unground 1 Straight Coolant Hole Carbide Rod is typically used as a raw material for further processing or customization. It provides a solid base for shaping and grinding into specific tool geometries based on the desired application.

| Part No. | D/mm | L/mm | d/mm | Tol. of D/mm | Tol. of L/mm | Tol. of d/mm | Grade (click here) |

|---|---|---|---|---|---|---|---|

| RHUK02003300-1S0020 | 2.0 | 330 | 0.20 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK02003300-1S0030 | 2.0 | 330 | 0.30 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK02003300-1S0040 | 2.0 | 330 | 0.40 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK02003300-1S0050 | 2.0 | 330 | 0.50 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK02003300-1S0060 | 2.0 | 330 | 0.60 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK02003300-1S0080 | 2.0 | 330 | 0.80 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK02003300-1S0100 | 2.0 | 330 | 1.00 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK03003300-1S0010 | 3.0 | 330 | 0.10 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK03003300-1S0020 | 3.0 | 330 | 0.20 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK03003300-1S0030 | 3.0 | 330 | 0.30 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK03003300-1S0040 | 3.0 | 330 | 0.40 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK03003300-1S0050 | 3.0 | 330 | 0.50 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK03003300-1S0060 | 3.0 | 330 | 0.60 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK03003300-1S0070 | 3.0 | 330 | 0.70 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK03003300-1S0080 | 3.0 | 330 | 0.80 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK03003300-1S0090 | 3.0 | 330 | 0.90 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK03003300-1S0100 | 3.0 | 330 | 1.00 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK03003300-1S0110 | 3.0 | 330 | 1.10 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK03003300-1S0120 | 3.0 | 330 | 1.20 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK03003300-1S0130 | 3.0 | 330 | 1.30 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK03003300-1S0140 | 3.0 | 330 | 1.40 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK03003300-1S0150 | 3.0 | 330 | 1.50 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK03003300-1S0160 | 3.0 | 330 | 1.60 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK03003300-1S0170 | 3.0 | 330 | 1.70 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK03003300-1S0180 | 3.0 | 330 | 1.80 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK03003300-1S0200 | 3.0 | 330 | 2.00 | +0.50/+0.25 | 0, +5 | ±0.20 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK04003300-1S0010 | 4.0 | 330 | 0.10 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK04003300-1S0020 | 4.0 | 330 | 0.20 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK04003300-1S0030 | 4.0 | 330 | 0.30 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK04003300-1S0040 | 4.0 | 330 | 0.40 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK04003300-1S0050 | 4.0 | 330 | 0.50 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK04003300-1S0060 | 4.0 | 330 | 0.60 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK04003300-1S0080 | 4.0 | 330 | 0.80 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK04003300-1S0100 | 4.0 | 330 | 1.00 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK04003300-1S0120 | 4.0 | 330 | 1.20 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK04003300-1S0130 | 4.0 | 330 | 1.30 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK04003300-1S0140 | 4.0 | 330 | 1.40 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK04003300-1S0150 | 4.0 | 330 | 1.50 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK04003300-1S0160 | 4.0 | 330 | 1.60 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK04003300-1S0190 | 4.0 | 330 | 1.90 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK04003300-1S0200 | 4.0 | 330 | 2.00 | +0.50/+0.25 | 0, +5 | ±0.20 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK04003300-1S0250 | 4.0 | 330 | 2.50 | +0.50/+0.25 | 0, +5 | ±0.25 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK05003300-1S0030 | 5.0 | 330 | 0.30 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK05003300-1S0040 | 5.0 | 330 | 0.40 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK05003300-1S0050 | 5.0 | 330 | 0.50 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK05003300-1S0060 | 5.0 | 330 | 0.60 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK05003300-1S0080 | 5.0 | 330 | 0.80 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK05003300-1S0090 | 5.0 | 330 | 0.90 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK05003300-1S0100 | 5.0 | 330 | 1.00 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK05003300-1S0110 | 5.0 | 330 | 1.10 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK05003300-1S0120 | 5.0 | 330 | 1.20 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK05003300-1S0150 | 5.0 | 330 | 1.50 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK05003300-1S0160 | 5.0 | 330 | 1.60 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK05003300-1S0200 | 5.0 | 330 | 2.00 | +0.50/+0.25 | 0, +5 | ±0.20 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK06003300-1S0020 | 6.0 | 330 | 0.20 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK06003300-1S0030 | 6.0 | 330 | 0.30 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK06003300-1S0050 | 6.0 | 330 | 0.50 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK06003300-1S0060 | 6.0 | 330 | 0.60 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK06003300-1S0080 | 6.0 | 330 | 0.80 | +0.50/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK06003300-1S0100 | 6.0 | 330 | 1.00 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK06003300-1S0120 | 6.0 | 330 | 1.20 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK06003300-1S0150 | 6.0 | 330 | 1.50 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK06003300-1S0160 | 6.0 | 330 | 1.60 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK06003300-1S0180 | 6.0 | 330 | 1.80 | +0.50/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK06003300-1S0200 | 6.0 | 330 | 2.00 | +0.50/+0.25 | 0, +5 | ±0.20 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK07003300-1S0050 | 7.0 | 330 | 0.50 | +0.60/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK07003300-1S0060 | 7.0 | 330 | 0.60 | +0.60/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK07003300-1S0100 | 7.0 | 330 | 1.00 | +0.60/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK07003300-1S0150 | 7.0 | 330 | 1.50 | +0.60/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK07003300-1S0300 | 7.0 | 330 | 3.00 | +0.60/+0.25 | 0, +5 | ±0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK08003300-1S0050 | 8.0 | 330 | 0.50 | +0.60/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK08003300-1S0060 | 8.0 | 330 | 0.60 | +0.60/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK08003300-1S0080 | 8.0 | 330 | 0.80 | +0.60/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK08003300-1S0100 | 8.0 | 330 | 1.00 | +0.60/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK08003300-1S0120 | 8.0 | 330 | 1.20 | +0.60/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK08003300-1S0150 | 8.0 | 330 | 1.50 | +0.60/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK08003300-1S0180 | 8.0 | 330 | 1.80 | +0.60/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK08003300-1S0200 | 8.0 | 330 | 2.00 | +0.60/+0.25 | 0, +5 | ±0.20 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK08003300-1S0250 | 8.0 | 330 | 2.50 | +0.60/+0.25 | 0, +5 | ±0.25 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK08003300-1S0300 | 8.0 | 330 | 3.00 | +0.60/+0.25 | 0, +5 | ±0.25 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK08003300-1S0350 | 8.0 | 330 | 3.50 | +0.60/+0.25 | 0, +5 | ±0.25 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK08003300-1S0400 | 8.0 | 330 | 4.00 | +0.60/+0.25 | 0, +5 | ±0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK09003300-1S0050 | 9.0 | 330 | 0.50 | +0.60/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK09003300-1S0150 | 9.0 | 330 | 1.50 | +0.60/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK09003300-1S0200 | 9.0 | 330 | 2.00 | +0.60/+0.25 | 0, +5 | ±0.20 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK09003300-1S0250 | 9.0 | 330 | 2.50 | +0.60/+0.25 | 0, +5 | ±0.25 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK10003300-1S0050 | 10.0 | 330 | 0.50 | +0.60/+0.25 | 0, +5 | ±0.10 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK10003300-1S0100 | 10.0 | 330 | 1.00 | +0.60/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK10003300-1S0120 | 10.0 | 330 | 1.20 | +0.60/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK10003300-1S0150 | 10.0 | 330 | 1.50 | +0.60/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK10003300-1S0180 | 10.0 | 330 | 1.80 | +0.60/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK10003300-1S0200 | 10.0 | 330 | 2.00 | +0.60/+0.25 | 0, +5 | ±0.20 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK10003300-1S0250 | 10.0 | 330 | 2.50 | +0.60/+0.25 | 0, +5 | ±0.25 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK10003300-1S0300 | 10.0 | 330 | 3.00 | +0.60/+0.25 | 0, +5 | ±0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK10003300-1S0600 | 10.0 | 330 | 6.00 | +0.60/+0.25 | 0, +5 | ±0.40 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK12003300-1S0150 | 12.0 | 330 | 1.50 | +0.60/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK12003300-1S0200 | 12.0 | 330 | 2.00 | +0.60/+0.25 | 0, +5 | ±0.20 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK12003300-1S0250 | 12.0 | 330 | 2.50 | +0.60/+0.25 | 0, +5 | ±0.25 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK12003300-1S0300 | 12.0 | 330 | 3.00 | +0.60/+0.25 | 0, +5 | ±0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK12003300-1S0600 | 12.0 | 330 | 6.00 | +0.60/+0.25 | 0, +5 | ±0.40 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK12003300-1S0650 | 12.0 | 330 | 6.50 | +0.60/+0.25 | 0, +5 | ±0.40 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK13003300-1S0350 | 13.0 | 330 | 3.50 | +0.70/+0.25 | 0, +5 | ±0.20 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK14003300-1S0300 | 14.0 | 330 | 3.00 | +0.70/+0.25 | 0, +5 | ±0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK15003300-1S0130 | 15.0 | 330 | 1.30 | +0.70/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK15003300-1S0150 | 15.0 | 330 | 1.50 | +0.70/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK16003300-1S0100 | 16.0 | 330 | 1.00 | +0.70/+0.25 | 0, +5 | ±0.15 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK16003300-1S0200 | 16.0 | 330 | 2.00 | +0.70/+0.25 | 0, +5 | ±0.20 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK16003300-1S0300 | 16.0 | 330 | 3.00 | +0.70/+0.25 | 0, +5 | ±0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK18003300-1S0300 | 18.0 | 330 | 3.00 | +0.80/+0.30 | 0, +5 | ±0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK20003300-1S0300 | 20.0 | 330 | 3.00 | +0.80/+0.25 | 0, +5 | ±0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK20003300-1S0400 | 20.0 | 330 | 4.00 | +0.80/+0.25 | 0, +5 | ±0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK22003300-1S0300 | 22.0 | 330 | 3.00 | +0.80/+0.25 | 0, +5 | ±0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK24003300-1S0400 | 24.0 | 330 | 4.00 | +0.80/+0.25 | 0, +5 | ±0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK25003300-1S0300 | 25.0 | 330 | 3.00 | +0.80/+0.25 | 0, +5 | ±0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK26003300-1S0400 | 26.0 | 330 | 4.00 | +0.80/+0.30 | 0, +5 | ±0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK28003300-1S0400 | 28.0 | 330 | 4.00 | +0.80/+0.25 | 0, +5 | ±0.30 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| RHUK32003300-1S0500 | 32.0 | 330 | 5.00 | +1.20/+0.30 | 0, +5 | ±0.40 | TS710, TS610, TU412, TU409, TU406, TN209, TS715 |

| Part No. | D/mm | L/mm | d/mm | Tol. of D/mm | Tol. of L/mm | Tol. of d/mm | Grade (click here) |

|---|---|---|---|---|---|---|---|

| RHUJ03003300-1S0050 | 3.0 | 330 | 0.50 | +0.30/+0.50 | 0, +5 | ±0.10 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ04003300-1S0080 | 4.0 | 330 | 0.80 | +0.30/+0.50 | 0, +5 | ±0.10 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ05003300-1S0080 | 5.0 | 330 | 0.80 | +0.30/+0.50 | 0, +5 | ±0.10 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ06003300-1S0100 | 6.0 | 330 | 1.00 | +0.30/+0.50 | 0, +5 | ±0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ07003300-1S0100 | 7.0 | 330 | 1.00 | +0.30/+0.60 | 0, +5 | ±0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ08003300-1S0100 | 8.0 | 330 | 1.00 | +0.30/+0.60 | 0, +5 | ±0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ09003300-1S0140 | 9.0 | 330 | 1.40 | +0.30/+0.60 | 0, +5 | ±0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ10003300-1S0140 | 10.0 | 330 | 1.40 | +0.30/+0.60 | 0, +5 | ±0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ11003300-1S0140 | 11.0 | 330 | 1.40 | +0.30/+0.60 | 0, +5 | ±0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ12003300-1S0175 | 12.0 | 330 | 1.75 | +0.30/+0.60 | 0, +5 | ±0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ13003300-1S0175 | 13.0 | 330 | 1.75 | +0.30/+0.70 | 0, +5 | ±0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ14003300-1S0175 | 14.0 | 330 | 1.75 | +0.30/+0.70 | 0, +5 | ±0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ15003300-1S0200 | 15.0 | 330 | 2.00 | +0.30/+0.70 | 0, +5 | ±0.20 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ16003300-1S0200 | 16.0 | 330 | 2.00 | +0.30/+0.70 | 0, +5 | ±0.20 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ17003300-1S0200 | 17.0 | 330 | 2.00 | +0.30/+0.80 | 0, +5 | ±0.20 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ18003300-1S0200 | 18.0 | 330 | 2.00 | +0.30/+0.80 | 0, +5 | ±0.20 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ19003300-1S0200 | 19.0 | 330 | 2.00 | +0.30/+0.80 | 0, +5 | ±0.20 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ20003300-1S0250 | 20.0 | 330 | 2.50 | +0.30/+0.80 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ21003300-1S0250 | 21.0 | 330 | 2.50 | +0.30/+0.80 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ22003300-1S0250 | 22.0 | 330 | 2.50 | +0.30/+0.80 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ23003300-1S0250 | 23.0 | 330 | 2.50 | +0.30/+0.80 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ24003300-1S0300 | 24.0 | 330 | 3.00 | +0.30/+0.80 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ25003300-1S0300 | 25.0 | 330 | 3.00 | +0.30/+0.80 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ26003300-1S0300 | 26.0 | 330 | 3.00 | +0.30/+0.80 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ27003300-1S0300 | 27.0 | 330 | 3.00 | +0.30/+0.80 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ28003300-1S0300 | 28.0 | 330 | 3.00 | +0.30/+0.80 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ29003300-1S0300 | 29.0 | 330 | 3.00 | +0.30/+0.80 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHUJ30003300-1S0300 | 30.0 | 330 | 3.00 | +0.30/+0.80 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

Ground 1 Straight Coolant Hole Carbide Rod Description

A ground 1 Straight Coolant Hole Carbide Rod is a cylindrical tool made of solid carbide material with a straight coolant hole running through its center. Unlike an unground carbide rod, the ground version has undergone precision grinding, resulting in a smooth and precisely finished surface.

The ground surface of the 1 Straight Coolant Hole Carbide Rod offers several advantages. It provides tight tolerances, ensuring precise dimensions and geometric accuracy. The coolant hole is precisely aligned and smooth, allowing for efficient coolant flow directly to the cutting edge during machining operations.

| Part No. | D/mm | L/mm | d/mm | Tol. of D/mm | Tol. of L/mm | Tol. of d/mm | Grade (click here) |

|---|---|---|---|---|---|---|---|

| RHGJ03003300-1S0050 | 3.0 | 330 | 0.50 | h6 | 0, +5 | ±0.10 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ04003300-1S0080 | 4.0 | 330 | 0.80 | h6 | 0, +5 | ±0.10 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ05003300-1S0080 | 5.0 | 330 | 0.80 | h6 | 0, +5 | ±0.10 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ06003300-1S0100 | 6.0 | 330 | 1.00 | h6 | 0, +5 | ±0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ07003300-1S0100 | 7.0 | 330 | 1.00 | h6 | 0, +5 | ±0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ08003300-1S0100 | 8.0 | 330 | 1.00 | h6 | 0, +5 | ±0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ09003300-1S0140 | 9.0 | 330 | 1.40 | h6 | 0, +5 | ±0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ10003300-1S0140 | 10.0 | 330 | 1.40 | h6 | 0, +5 | ±0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ11003300-1S0140 | 11.0 | 330 | 1.40 | h6 | 0, +5 | ±0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ12003300-1S0175 | 12.0 | 330 | 1.75 | h6 | 0, +5 | ±0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ13003300-1S0175 | 13.0 | 330 | 1.75 | h6 | 0, +5 | ±0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ14003300-1S0175 | 14.0 | 330 | 1.75 | h6 | 0, +5 | ±0.15 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ15003300-1S0200 | 15.0 | 330 | 2.00 | h6 | 0, +5 | ±0.20 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ16003300-1S0200 | 16.0 | 330 | 2.00 | h6 | 0, +5 | ±0.20 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ17003300-1S0200 | 17.0 | 330 | 2.00 | h6 | 0, +5 | ±0.20 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ18003300-1S0200 | 18.0 | 330 | 2.00 | h6 | 0, +5 | ±0.20 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ19003300-1S0200 | 19.0 | 330 | 2.00 | h6 | 0, +5 | ±0.20 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ20003300-1S0250 | 20.0 | 330 | 2.50 | h6 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ21003300-1S0250 | 21.0 | 330 | 2.50 | h6 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ22003300-1S0250 | 22.0 | 330 | 2.50 | h6 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ23003300-1S0250 | 23.0 | 330 | 2.50 | h6 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ24003300-1S0300 | 24.0 | 330 | 3.00 | h6 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ25003300-1S0300 | 25.0 | 330 | 3.00 | h6 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ26003300-1S0300 | 26.0 | 330 | 3.00 | h6 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ27003300-1S0300 | 27.0 | 330 | 3.00 | h6 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ28003300-1S0300 | 28.0 | 330 | 3.00 | h6 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ29003300-1S0300 | 29.0 | 330 | 3.00 | h6 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

| RHGJ30003300-1S0300 | 30.0 | 330 | 3.00 | h6 | 0, +5 | ±0.25 | TN209, TU406, TU412, TS610, TU408, TU510, TU512A, TU512B, TS606, TS613, TM1512, TM2214 |

- Contact

Our team is ready to provide support

Truer Carbide is committed to providing efficient solutions to problems. Each team member has the expertise and experience to quickly understand and meet your needs.