Why Is Tungsten Carbide Material Suitable for Medical Tools?

Tungsten carbide is a powerhouse material in the medical industry, widely preferred for surgical instruments, dental tools, and orthopedic applications. But why? Because it offers exceptional hardness, wear resistance, and biocompatibility—key factors for medical tools that require precision and durability.

Unlike stainless steel, which can wear down over time, tungsten carbide is almost twice as rigid and maintains sharp edges longer. This means medical tools made from carbide rods stay sharper for extended periods, reducing the need for frequent replacements. Moreover, its high resistance to corrosion and sterilization methods makes it ideal for repeated use in hospital environments. Whether in high-speed dental drills or delicate surgical scissors, tungsten carbide ensures performance, reliability, and longevity.

Why Use Carbide Rods for Medical Tools?

Medical professionals demand instruments that can withstand extreme conditions. Carbide rods provide the necessary mechanical strength and edge retention required for precise surgical procedures.

- Unmatched Durability – Compared to traditional metals, carbide rods exhibit greater wear resistance and maintain sharp cutting edges, making them perfect for high-precision tools like scalpels and endoscopic instruments.

- Superior Hardness – On the Mohs scale, tungsten carbide ranks 9 out of 10, just below diamond. This level of hardness allows for fine, sharp edges in medical blades, needles, and drills.

- Corrosion Resistance – Unlike some metals that degrade with exposure to sterilization chemicals, carbide maintains its structural integrity.

- Biocompatibility – Many tungsten carbide alloys are non-toxic and safe for prolonged contact with human tissue.

- Heat Resistance – Medical procedures often require tools that endure high temperatures. Tungsten carbide’s heat resistance makes it ideal for tools used in laser surgery and cauterization.

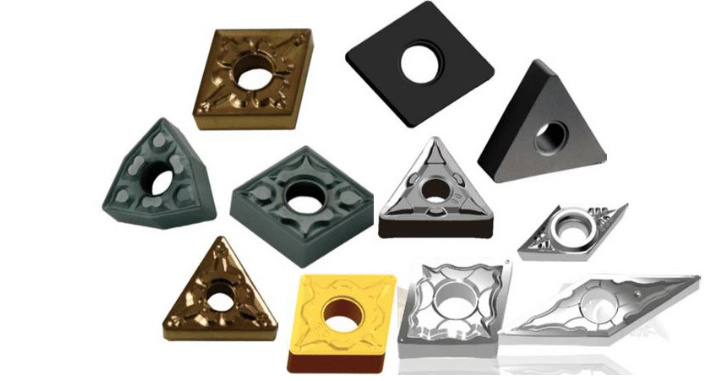

Common Applications in the Medical Industry

Carbide rods play a crucial role in manufacturing high-precision medical tools. Here are some common applications:

- Dental Drills & Burs – High-speed tungsten carbide dental burs outperform traditional steel burs in precision and longevity.

- Surgical Blades & Scalpels – Extremely sharp and durable for procedures requiring precision.

- Orthopedic Pins & Needles – Used in bone surgeries due to their high strength and non-reactive properties.

- Micro-Cutting Instruments – Applied in delicate eye surgeries where sharpness is critical.

- Endoscopic Surgical Tools – The fine cutting edges improve the accuracy of minimally invasive surgeries.

How to Choose High-Quality Carbide Rods?

| Factor | Importance | Description |

|---|---|---|

| Grain Size | High | The finer the grain, the sharper and more durable the tool. Ideal for scalpels and micro-cutting instruments. |

| Cobalt Content | Medium | High cobalt increases toughness but reduces wear resistance. Low cobalt is preferable for high-precision cutting tools. |

| Hardness Rating | Critical | Measured in HRA (Rockwell Hardness), medical-grade carbide rods should be above 90 HRA. |

| Coating | High | Titanium and nano-coatings enhance wear resistance and extend tool life. |

| Flexural Strength | Medium | A balance between rigidity and fracture resistance is essential for durability. |

Leading Manufacturers & Suppliers of Carbide Rods

| Manufacturer | Specialization | Notable Products |

|---|---|---|

| Sandvik | Medical cutting tools | Precision carbide burrs and drills |

| Kennametal | Orthopedic instruments | High-precision carbide scalpels |

| Ceratizit | Dental applications | Carbide dental burs and rotary tools |

| Hyperion | High-performance tools | Nano-coated carbide blades |

| Zhuzhou Cemented Carbide | Surgical & micro-tools | Fine-grain carbide rods for micro-surgical instruments |

| Mitsubishi Materials | Endoscopic surgery tools | Ultra-sharp tungsten carbide cutting tips |

| Komet Dental | Dental surgery | High-speed carbide drill bits |

| Sumitomo Electric | Biocompatible materials | Corrosion-resistant carbide tools |

| Weily Carbide | Custom medical tools | High-tolerance carbide pins & needles |

| CF Tungsten | Orthopedic devices | Ultra-hard carbide rods for bone drills |

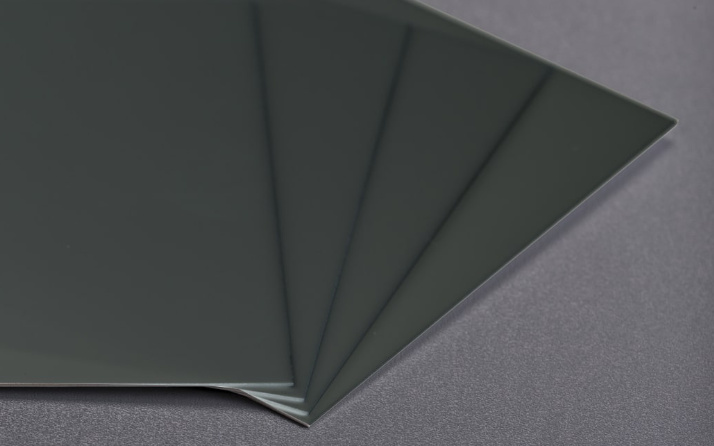

The Application Prospects of New Coating Technology & Nanoscale Tungsten Carbide

The future of medical carbide tools is evolving with nano-coating technologies and nanoscale tungsten carbide. These advancements provide enhanced durability, sharper edges, and increased resistance to sterilization damage.

Nano-coatings like TiN (Titanium Nitride) and DLC (Diamond-Like Carbon) significantly improve wear resistance while reducing friction—ideal for microsurgical tools and robotic-assisted surgeries. Meanwhile, nanoscale tungsten carbide particles result in even finer grain structures, improving edge retention and overall tool longevity.

Medical professionals are increasingly opting for these next-gen carbide materials, ensuring even more precision and reliability in life-saving procedures.

FAQ

| Question | Answer |

|---|---|

| Why are carbide rods preferred over stainless steel? | Carbide rods have higher hardness, superior edge retention, and greater wear resistance than stainless steel, making them ideal for precision tools. |

| Are tungsten carbide medical tools safe? | Yes, medical-grade tungsten carbide is biocompatible and non-toxic, ensuring safe usage. |

| Do carbide medical tools require frequent sharpening? | No, carbide tools maintain their sharpness for much longer than traditional steel instruments. |

| What’s the best coating for carbide medical tools? | Nano-coatings like TiN or DLC enhance durability, reduce friction, and improve longevity. |

| How do I ensure I’m purchasing high-quality carbide rods? | Look for factors such as grain size, hardness rating (HRA 90+), and reputable manufacturers. |