Woodworking has come a long way from simple hand tools to advanced machinery designed to create precision cuts and finishes. At the core of many modern tools lies carbide, a material that has revolutionized woodworking. In this article, we’ll explore the world of carbide for woodworking in detail—its properties, applications, advantages, and how to choose the right type for your needs.

What Is a Carbide Rod for End Mills?

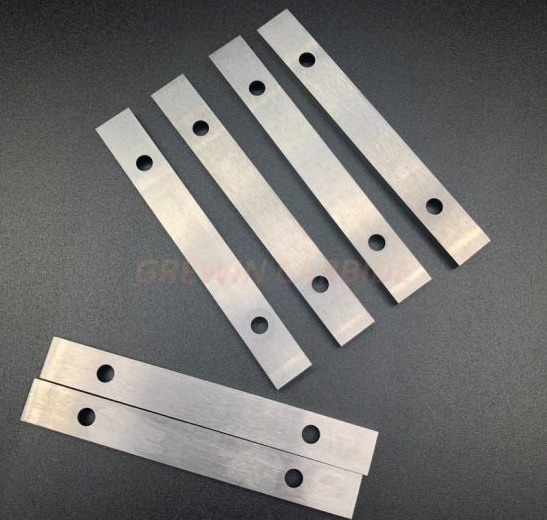

Carbide rods are cylindrical materials made from tungsten carbide powder, often combined with other metallic elements like cobalt to enhance toughness and wear resistance. They are widely used to manufacture end mills, drills, and other cutting tools for woodworking.

Why are they so special? Imagine trying to slice through dense hardwood with a butter knife. The knife would dull in seconds. Now picture using a razor-sharp blade designed specifically for the job—that’s what carbide does for woodworking tools. Its hardness and durability make it the go-to material for high-precision cutting and prolonged tool life.

The Importance of Carbide for Woodworking in Tool Manufacturing

Woodworking tools are subjected to intense pressure, friction, and wear. Tools crafted from carbide have an edge—literally and figuratively. Carbide is exceptionally hard (ranking close to diamonds on the Mohs scale), heat-resistant, and wear-resistant. These properties ensure tools maintain their sharpness longer, reduce downtime for sharpening, and achieve cleaner cuts.

For example, imagine carving intricate details into oak. A carbide-tipped router bit stays sharper much longer than a standard steel bit, resulting in smoother finishes and greater efficiency. It’s no surprise that carbide has become the gold standard in woodworking.

What Is a Carbide for Woodworking?

| Property | Description |

|---|---|

| Composition | Made from tungsten carbide and binding materials like cobalt. |

| Hardness | Extremely hard, ranking around 9 on the Mohs scale. |

| Heat Resistance | Withstands high temperatures without losing structural integrity. |

| Durability | Long-lasting performance, even under heavy usage. |

| Applications | Used in saw blades, router bits, end mills, and drill bits for woodworking. |

Advantages of Carbide Rods in End Mills

- Superior Hardness: Carbide rods are harder than most metals, ensuring longevity and less frequent replacements. Imagine the frustration of constantly changing dull tools—with carbide, that’s a rare occurrence.

- Heat Resistance: Woodworking generates significant heat, especially when cutting at high speeds. Carbide remains unaffected, maintaining performance where other materials fail.

- Precision: Want those perfectly smooth edges on your projects? Carbide tools are precise, giving you unparalleled accuracy.

- Cost-Effectiveness: Though initially pricier, carbide tools save money in the long run by lasting significantly longer than traditional materials.

How to Choose the Right Carbide Rod for End Mills

Choosing the right carbide rod for your end mill is akin to selecting the right ingredients for a recipe. Here’s what to consider:

- Grade of Carbide: Different grades cater to specific applications. For woodworking, grades with high wear resistance are preferred.

- Diameter: Match the rod’s diameter to your tool’s requirements.

- Coating: Coated carbide rods, such as those with titanium nitride (TiN), provide added heat resistance and smoother cutting.

- Application Needs: Are you working on softwoods or hardwoods? For tougher woods, choose rods with higher toughness.

Applications of Carbide Rods in End Mills

| Application | Description |

|---|---|

| Cutting Tools | Ideal for creating sharp-edged tools like end mills, router bits, and drills. |

| Drilling | Precision drilling through dense wood or composites. |

| Shaping | Used in lathe tools for shaping and profiling. |

| Engraving | Perfect for intricate designs and carvings. |

| Planing | Helps in achieving smooth surfaces with minimal effort. |

Comparing Carbide Rods to Alternative Materials

| Material | Advantages | Limitations |

|---|---|---|

| Carbide | Hard, heat-resistant, durable, precise. | Higher initial cost. |

| High-Speed Steel | Cheaper, easier to machine. | Dulls quickly, less heat-resistant. |

| Ceramics | Excellent heat resistance, very hard. | Brittle, prone to chipping. |

| Tool Steel | Affordable, good toughness. | Not as hard or heat-resistant as carbide. |

FAQs

| Question | Answer |

|---|---|

| What makes carbide tools better for woodworking? | Their hardness, heat resistance, and durability make them ideal for precision and long-lasting use. |

| Are carbide tools more expensive? | Yes, but they save money over time due to their longevity. |

| Can I sharpen carbide tools? | Yes, but it requires special diamond grinding equipment. |

| Do carbide tools work on all types of wood? | Yes, they handle both softwoods and hardwoods with ease. |

| How do I maintain carbide tools? | Clean them regularly and avoid excessive heat or impact during use. |