Carbide punch strips – those unassuming yet mighty tools – are the unsung heroes behind countless manufacturing processes. Their ability to punch, pierce, and shape materials with unwavering precision makes them indispensable in industries ranging from electronics to automotive. Join us as we delve into the fascinating world of carbide punch strips, exploring their composition, applications, and the factors that make them essential for demanding fabrication tasks.

What Exactly Are Carbide Punch Strips?

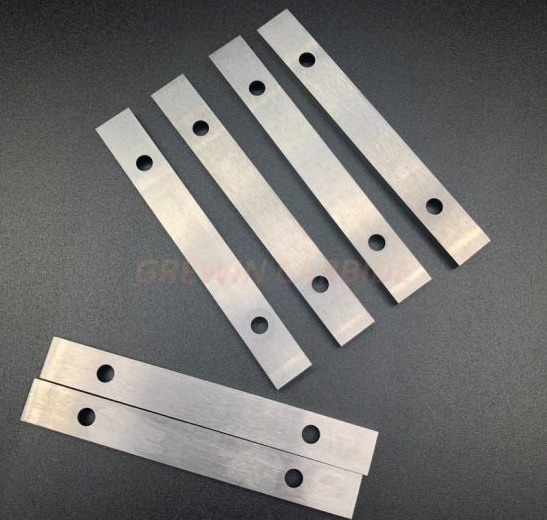

Carbide punch strips are thin, flat pieces of cemented carbide, a composite material renowned for its exceptional hardness and wear resistance. These strips are specifically engineered to withstand the extreme forces and friction encountered during punching and forming operations. Their secret lies in their unique composition:

- Tungsten Carbide: The primary ingredient, tungsten carbide, boasts a hardness approaching that of diamond, providing unmatched resistance to wear and abrasion.

- Cobalt Binder: Acting as a metallic glue, cobalt binds the tungsten carbide particles together, providing the necessary toughness and impact resistance to withstand repeated punching cycles.

From Powder to Punch: The Manufacturing Journey of Carbide Punch Strips

The creation of carbide punch strips is a testament to precision engineering:

- Powder Metallurgy: Finely ground powders of tungsten carbide and cobalt are meticulously blended in specific ratios to achieve the desired properties for punching applications.

- Pressing and Shaping: The powder mixture is then subjected to immense pressure within specialized molds, forming the initial shape of the strips.

- Sintering: The Fusion of Strength: The pressed strips undergo a high-temperature sintering process in a controlled atmosphere. During sintering, the cobalt binder melts and fuses the tungsten carbide particles together, forming a solid, incredibly dense material.

- Precision Grinding and Finishing: After sintering, the carbide strips are meticulously ground and finished to achieve the precise dimensions, tolerances, and surface quality required for punching applications.

A Strip for Every Punch: Types and Properties of Carbide Punch Strips

Carbide punch strips are not a one-size-fits-all solution. They come in various grades, sizes, and configurations, each tailored for specific punching applications and materials. Here’s a glimpse into their diversity:

Carbide Punch Strips: Decoding Their Properties

| Property | Description | Typical Values |

|---|---|---|

| Hardness (HRA) | Resistance to scratching and indentation | 88-95 |

| Transverse Rupture Strength (TRS) | Ability to withstand bending forces without breaking | 1500-3000 N/mm² |

| Compressive Strength | Resistance to deformation under compression | 4000-6000 N/mm² |

| Grain Size | Size of the tungsten carbide particles, influencing hardness and wear resistance | 0.5-10 µm |

| Cobalt Content | Percentage of cobalt binder, impacting toughness and wear resistance | 6-12% |

Table 1: Key Properties of Carbide Punch Strips

Punching Above Their Weight: Applications of Carbide Punch Strips

Carbide punch strips are the driving force behind precision punching in a multitude of industries:

1. Electronics: Shaping the Digital World

- Printed Circuit Boards (PCBs): Carbide punch strips create precise holes and cutouts in PCBs for mounting electronic components, ensuring accurate circuit connections.

- Semiconductor Manufacturing: Used in wafer dicing and packaging processes, ensuring precise separation and handling of delicate semiconductor chips.

2. Automotive: Powering Precision in Every Part

- Metal Stamping: Carbide punch strips create holes, slots, and other features in sheet metal parts for automotive bodies, frames, and components.

- Fuel Injection Systems: Used to manufacture precise nozzles and components for fuel injection systems, ensuring optimal fuel atomization and engine performance.

3. Beyond the Assembly Line:

The versatility of carbide punch strips extends to a wide range of other industries, including:

- Aerospace: Punching holes and slots in lightweight materials for aircraft components.

- Medical: Creating precise openings and features in surgical instruments and medical devices.

- Packaging: Manufacturing dies for cutting and shaping packaging materials.

The Competitive Edge: Comparing Carbide Punch Strip Suppliers

| Supplier | Location | Price Range (per piece) | Specialties |

|---|---|---|---|

| TRUER | Global | $10 – $80 | Custom carbide solutions, high-performance grades for demanding punching applications |

| Element Six | Global | $15 – $100 | Wide range of standard and specialized grades, advanced coatings for extended tool life |

| Sandvik Coromant | Sweden | $20 – $120 | Advanced geometries and coatings for high-volume punching and challenging materials |

| Kennametal | US | $12 – $90 | High-quality carbide punch strips for various industries, including automotive and electronics |

Table 2: Comparing Carbide Punch Strip Suppliers

Note: Prices are approximate and may vary depending on grade, size, quantity, and market conditions.

A Balanced Perspective: Advantages and Limitations of Carbide Punch Strips

Carbide Punch Strips: Weighing the Pros and Cons

| Advantages | Limitations |

|---|---|

| Exceptional hardness and wear resistance, ensuring long tool life | Relatively brittle, susceptible to chipping or fracture under extreme impact or side loads |

| High dimensional accuracy and precision, enabling the creation of intricate parts | Can be expensive compared to other tooling materials, especially for complex geometries |

| Ability to punch a wide range of materials, from thin foils to thick plates | Requires specialized equipment and expertise for machining and sharpening |

| Resistance to high temperatures and pressures, making them suitable for demanding applications | May not be suitable for all punching applications, particularly those involving very large or irregularly shaped holes |

Table 3: Advantages and Limitations of Carbide Punch Strips

Beyond the Punch Press: Interesting Facts About Carbide

- From Mining to Manufacturing: Tungsten, the key component of tungsten carbide, derives its name from the Swedish words “tung sten,” meaning “heavy stone.” It was initially used in mining tools due to its extreme hardness.

- A Material of Extremes: Tungsten carbide has the highest melting point of all metals, reaching a scorching 3,422 degrees Celsius (6,192 degrees Fahrenheit).

- A Sustainable Choice: Tungsten carbide is an incredibly durable material, and tools made from it can be resharpened multiple times, reducing waste and promoting sustainability.

Why Choose TRUER for Your Carbide Punch Strip Needs?

At TRUER, we are dedicated to providing carbide solutions that empower our customers to achieve exceptional punching performance. Here’s why TRUER stands out:

- Uncompromising Quality: We source the highest quality tungsten carbide materials and employ stringent quality control measures throughout our manufacturing process.

- Custom Solutions: We specialize in tailoring carbide punch strips to meet your unique specifications, from grade and geometry to size and finish.

- Technical Expertise: Our team of carbide experts provides expert guidance and support, helping you select the optimal carbide solution for your punching application.

- Global Reach: With a global presence, we provide timely delivery and responsive customer service wherever you are in the world.

FAQs: Addressing Your Carbide Punch Strip Queries

1. What factors influence the lifespan of a carbide punch strip?

The lifespan of a carbide punch strip depends on several factors, including:

– Carbide Grade: Higher-grade carbide strips generally offer longer tool life.

– Material Being Punched: Punching abrasive or high-strength materials can reduce tool life.

– Punching Conditions: Punching speed, lubrication, and material thickness influence wear rates.

– Maintenance: Proper sharpening, cleaning, and storage can significantly prolong the lifespan of carbide punch strips.

2. Can carbide punch strips be coated?

Yes, carbide punch strips can be coated with various materials to enhance their performance. Common coatings include:

– Titanium Nitride (TiN): Increases hardness, reduces friction, and improves wear resistance.

– Titanium Carbonitride (TiCN): Offers even higher hardness and wear resistance than TiN.

– Diamond-Like Carbon (DLC): Provides exceptional lubricity and wear resistance, particularly for punching abrasive materials.

3. What are the key considerations when designing a punch and die set using carbide strips?

Designing effective punch and die sets using carbide strips involves considering factors such as:

– Clearance: The space between the punch and die, crucial for controlling material flow and preventing damage.

– Stripping Force: The force required to remove the punched material from the die, influencing punch and die design.

– Material Thickness and Properties: The type and thickness of the material being punched impact punch and die geometry.

4. How do I choose the right carbide grade for my punching application?

Selecting the appropriate carbide grade involves considering factors such as:

– Material Being Punched: Different carbide grades are optimized for punching specific materials (e.g., steel, aluminum, copper).

– Punching Force and Speed: Higher forces and speeds may require tougher carbide grades.

– Required Tool Life: Applications demanding long tool life benefit from higher-grade carbide strips.

5. What are the safety precautions for handling and using carbide punch strips?

Due to their extreme hardness and potential for chipping, handle carbide punch strips with care:

– Wear Safety Glasses: Protect your eyes from flying chips or debris.

– Use Gloves: Prevent cuts from sharp edges.

– Handle with Care: Avoid dropping or impacting the strips to prevent chipping or breakage.