The Importance of Carbide Plates in the Manufacturing Industry

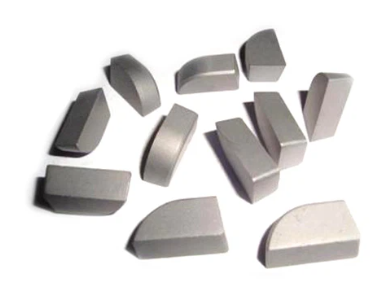

Carbide plates, often referred to as tungsten carbide plates, play a pivotal role in the manufacturing sector. Why? They’re the unsung heroes behind countless industrial applications, offering unmatched hardness, wear resistance, and versatility. Think of them as the sturdy backbone of high-stress machining, tooling, and cutting operations. Without these marvels, industries like aerospace, automotive, and mining would struggle to maintain efficiency and precision.

These plates are crafted using a combination of tungsten carbide powder and cobalt as a binder. The result? A material that’s tougher than nails—literally! Whether you’re cutting through metals or shaping components, carbide plates ensure the job gets done faster and better. As global demand for precision engineering grows, so does the reliance on carbide plates to keep things running smoothly.

Why Is It Crucial to Understand Carbide Plate Import Regulations?

Imagine this: you’re a manufacturer relying on carbide plates for your production line. Suddenly, a shipment is delayed or confiscated due to compliance issues. Frustrating, isn’t it? That’s why understanding import regulations isn’t just a good idea—it’s a necessity.

Import regulations ensure that the quality, safety, and environmental standards of carbide plates are upheld. These rules protect industries from subpar materials, which could lead to equipment failures, production downtime, or even accidents. Additionally, compliance with import laws prevents hefty fines, legal troubles, and reputational damage for businesses. Knowing the ins and outs of these regulations can be the difference between smooth operations and costly disruptions.

What Is a Carbide Plate and What Is Its Main Purpose?

| Feature | Description |

|---|---|

| Material Composition | Made from tungsten carbide powder combined with cobalt or nickel as a binder. |

| Key Properties | High hardness, wear resistance, corrosion resistance, and thermal stability. |

| Primary Applications | Used in cutting tools, dies, punches, wear parts, and various machining applications. |

| Advantages Over Alternatives | Longer lifespan, higher precision, and better performance under extreme conditions. |

Carbide plates are the go-to choice for any application requiring durability and precision. Their ability to withstand high pressure and extreme temperatures makes them indispensable in industries demanding reliability.

Basic Overview of Carbide Plate Import Regulations

Importing carbide plates isn’t as simple as placing an order and waiting for delivery. There’s a complex web of regulations to navigate, which vary depending on the country of origin and destination. Here’s a breakdown of the key considerations:

- Material Standards: Imported carbide plates must meet specific quality and safety standards, such as ISO certifications or ASTM standards.

- Customs Documentation: Accurate paperwork, including certificates of origin, invoices, and material safety data sheets (MSDS), is mandatory.

- Tariffs and Duties: Import taxes can significantly impact costs, depending on trade agreements between countries.

- Environmental Compliance: Some countries require proof that the production and transport of carbide plates comply with environmental regulations.

- Restricted Items: Certain grades or types of carbide plates may be subject to export controls due to their potential use in military applications.

Understanding these factors ensures smooth transactions and avoids delays or penalties.

Import Policies of Carbide Plates in Different Countries

United States

The U.S. has stringent regulations for importing carbide plates. Importers must comply with ASTM standards, provide detailed documentation, and adhere to environmental protection laws. Additionally, duties may vary based on the country of origin.

European Union

The EU emphasizes environmental compliance and safety. REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations apply to the import of tungsten carbide products. Importers must also consider CE marking requirements for specific applications.

China

China, as a major producer of tungsten carbide, imposes fewer restrictions on imports but emphasizes quality control. Importers need to ensure compliance with GB (Guobiao) standards.

India

India requires importers to obtain BIS (Bureau of Indian Standards) certification for carbide plates. Additional customs duties and GST may apply, depending on the product’s classification.

Japan

Japan’s import policies focus on high-quality standards and strict documentation. Importers must align with JIS (Japanese Industrial Standards) and ensure accurate labeling.

Possible Issues That Importers of Carbide Plates May Encounter

Importing carbide plates isn’t without challenges. Here are some common hurdles:

- Customs Delays: Missing or incorrect documentation can lead to shipment holds.

- Quality Discrepancies: Imported plates might not meet specified standards, causing operational issues.

- High Tariffs: Unexpected duties can inflate costs.

- Counterfeit Products: The market is rife with subpar or fake carbide plates, especially from unverified suppliers.

- Regulatory Updates: Changing laws and standards can catch importers off guard, leading to non-compliance.

Navigating these issues requires meticulous planning and a reliable supply chain.

How to Choose a Trustworthy Supplier for Carbide Plates

| Criteria | Why It Matters |

|---|---|

| Certifications | Ensure the supplier has ISO, ASTM, or equivalent certifications to guarantee quality. |

| Experience | Look for suppliers with a proven track record in the carbide plate industry. |

| Transparency | A trustworthy supplier provides detailed specifications, pricing, and documentation upfront. |

| Customer Reviews | Check reviews and testimonials to gauge customer satisfaction. |

| Supply Chain Reliability | Evaluate their ability to handle large orders and deliver on time. |

| After-Sales Support | Reliable suppliers offer post-purchase support, such as technical assistance or replacement policies. |

By vetting suppliers based on these criteria, importers can minimize risks and ensure consistent quality.

FAQs

| Question | Answer |

|---|---|

| What documents are required for importing carbide plates? | Commonly required documents include invoices, certificates of origin, MSDS, and compliance certifications. |

| Are there restrictions on specific carbide grades? | Yes, some grades may be restricted due to dual-use concerns or export control regulations. |

| How can I verify the quality of imported carbide plates? | Request third-party testing or certification to confirm compliance with international standards. |

| What are common tariffs for carbide plates? | Tariffs vary by country and trade agreements; consult with customs authorities for accurate rates. |

| How can I avoid counterfeit products? | Source from reputable suppliers with verified credentials and strong industry presence. |