- Carbide plate

Carbide plate

As the backbone of stamping and metal forming, tungsten carbide EDM blocks resist the corrosion, pitting, and cracking commonly experienced during electrical discharge machining, especially in thick punches and large die segments.

We offer a wide variety of carbide grades for EDM blocks, including fine, medium, and course-grained tungsten carbides with a mixture of binders and additives to create the right balance of toughness, hardness, abrasion and corrosion resistance of the application.

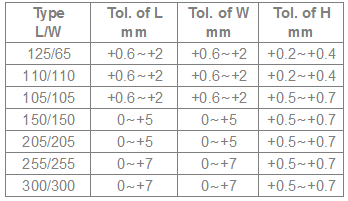

A comprehensive standard selection of tungsten carbide EDM blocks in various dimensions for each grade is available in the below tables, but other sizes, tolerances & configurations also available on request.

Contact us if what you need is not shown here.

Introduction

A carbide plate is a flat and rigid component made from tungsten carbide and a binder material. It exhibits exceptional hardness, wear resistance, and strength, making it suitable for a wide range of industrial applications. Carbide plates are commonly used in cutting tools, wear parts, tooling dies, and other high-wear and high-strength applications where durability and performance are essential. Their precision manufacturing and superior material properties make carbide plates a reliable choice for demanding machining and industrial environments.

Composition and Structure

The composition of carbide plates can vary depending on the specific application and manufacturer. Different grades of tungsten carbide and binder materials are selected to achieve desired properties such as hardness, toughness, and resistance to corrosion or thermal degradation.

In terms of structure, carbide plates are typically manufactured through a process called powder metallurgy. In this process, the tungsten carbide particles and binder material powders are thoroughly mixed, forming a homogenous mixture. The mixture is then compacted under high pressure into the desired plate shape.

Exceptional Hardness

Carbide plates exhibit exceptional hardness, often ranking among the hardest materials available. This property enables them to withstand high levels of wear and abrasion.

Superior Wear Resistance

Carbide plates are known for their excellent wear resistance, making them suitable for applications involving high levels of friction and mechanical stress.

High Strength

Carbide plates have high strength, allowing them to withstand heavy loads and impacts without deformation or breakage.

Excellent Thermal Stability

These plates have excellent thermal stability, enabling them to maintain their hardness and strength even at elevated temperatures.

Corrosion Resistance

Carbide plates are resistant to corrosion and oxidation, making them suitable for use in harsh and corrosive environments.

Dimensional Stability

Carbide plates exhibit excellent dimensional stability, maintaining their shape and dimensions under varying operating conditions.

Low Coefficient of Friction

Carbide plates have a low coefficient of friction, reducing the energy losses due to friction during sliding or rubbing applications.

Versatility

Carbide plates are versatile and can be used in a wide range of applications, including cutting tools, wear parts, tooling dies, and industrial machinery components.

Raw Material Selection

Carefully chosen tungsten carbide powder and binder materials based on desired properties.

Mixing

Thoroughly mix the tungsten carbide powder and binder materials to create a homogeneous mixture.

Compacting

Apply high pressure to the mixture, compacting it into a green compact shape.

Pre-Sintering

Pre-sinter the green compact at a temperature below the final sintering temperature.

Sintering

Heat the pre-sintered compact to bond the tungsten carbide particles, forming a solid structure.

Shaping and Machining

Shape and machine the sintered plate to achieve desired dimensions and surface finish.

Surface Treatment

This process is optional. Apply coatings or polish the surface as needed.

Quality Control

Implement stringent quality checks throughout the process to ensure the plate meets specifications.

Cutting Tools

Carbide plates are widely used for the manufacturing of cutting tools such as inserts, drills, milling cutters, and saw blades. Their exceptional hardness, wear resistance, and strength make them ideal for high-speed cutting operations.

Wear Parts

Carbide plates find applications in wear parts such as punches, dies, and nozzles, where resistance to abrasion, erosion, and impact is crucial. They provide extended service life and reliability in demanding industrial environments.

Tooling Dies

Carbide plates are utilized in tooling dies for various industries, including metal stamping, forging, and extrusion. Their high hardness and dimensional stability enable precise and repeatable forming operations.

Industrial Machinery Components

Carbide plates are employed in a wide range of industrial machinery components, including wear plates, bushings, and guide rails. They offer durability, resistance to wear and corrosion, and enhanced performance in heavy-duty applications.

Cutting Tools

Carbide plates are widely used for the manufacturing of cutting tools such as inserts, drills, milling cutters, and saw blades. Their exceptional hardness, wear resistance, and strength make them ideal for high-speed cutting operations.

Wear Parts

Carbide plates find applications in wear parts such as punches, dies, and nozzles, where resistance to abrasion, erosion, and impact is crucial. They provide extended service life and reliability in demanding industrial environments.

Tooling Dies

Carbide plates are utilized in tooling dies for various industries, including metal stamping, forging, and extrusion. Their high hardness and dimensional stability enable precise and repeatable forming operations.

Industrial Machinery Components

Carbide plates are employed in a wide range of industrial machinery components, including wear plates, bushings, and guide rails. They offer durability, resistance to wear and corrosion, and enhanced performance in heavy-duty applications.

A carbide plate is a rigid component made from tungsten carbide and a binder material. It exhibits exceptional hardness, wear resistance, and strength, making it suitable for various industrial applications.

Carbide plates are not your ordinary metal plates. They are engineered for extreme conditions, crafted primarily from tungsten carbide, a material renowned for its exceptional hardness. This hardness, often measuring 85-95 on the Rockwell A scale (HRA), surpasses even the toughest steels, making carbide plates incredibly resistant to wear and tear.

A tungsten carbide plate is a flat, rectangular piece made from tungsten carbide, a compound of tungsten and carbon. This material is celebrated for its extreme hardness, surpassing many other industrial materials. The plates are often utilized in environments where high wear and tear are expected, making them ideal for cutting, grinding, and wear-resistant applications.

EDM, also known as spark machining or spark eroding, is a non-traditional machining process that utilizes controlled electrical discharges to remove material from a workpiece. Unlike conventional machining that relies on mechanical forces, EDM harnesses the power of precisely controlled electrical sparks to erode material with remarkable accuracy, even for the hardest materials like tungsten carbide.

Cemented carbide plates, often referred to as tungsten carbide plates, are composite materials made from tungsten carbide particles bonded together with a metallic binder, typically cobalt. This combination results in a material that is extremely hard and resistant to wear and deformation.

Ring series carbide plates, also known as ring segments or wear rings, are precision-engineered components typically crafted from tungsten carbide, a material renowned for its exceptional hardness and wear resistance. Unlike conventional flat carbide plates, these rings feature a distinct circular or semi-circular shape with a central bore, allowing them to be fitted around shafts, cylinders, or other rotating or reciprocating components.

Carbide plates are utilized in numerous applications owing to their high hardness and wear resistance. Key uses include:

- Tooling Components: Such as cutting tools, punches, and dies.

- Wear Parts: In machinery and equipment, including liners and wear surfaces.

- Metal Forming: Dies and molds for shaping metals.

- Mining and Construction Tools: Including wear-resistant parts for excavation and drilling.

Their robustness makes them ideal for high-stress, high-wear environments.

Yes, carbide plates can be customized to meet specific requirements, including dimensions, shapes, and surface treatments, based on the application needs.

Carbide plates have good resistance to corrosion and oxidation, making them suitable for use in corrosive environments.

Choosing carbide plates for your manufacturing needs ensures access to high-quality, precision-engineered tools that meet the stringent demands of modern industries. The benefits include:

- Superior Quality: Manufactured to the highest standards with rigorous quality control.

- Custom Solutions: Ability to tailor plates to specific applications and requirements.

- Innovation: Continuous development of new geometries and coatings to enhance performance.

- Support: Comprehensive customer service and technical support to assist with product selection and usage.

Data

EDM Blocks Description

EDM (Electrical Discharge Machining) blocks carbide plate is a specialized type of carbide plate used in EDM processes. It is designed to provide excellent electrical conductivity, thermal stability, and dimensional accuracy during the EDM machining operations.

These carbide plates are specifically engineered to withstand the high temperatures, electrical discharges, and rapid erosion associated with EDM applications. They exhibit high hardness, wear resistance, and strength, ensuring prolonged durability and performance.

| Part No. | L/mm | W/mm | H/mm | Grade (click here) |

|---|---|---|---|---|

| BJ125065015 | 125 | 65 | 1.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065020 | 125 | 65 | 2.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065025 | 125 | 65 | 2.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065030 | 125 | 65 | 3.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065035 | 125 | 65 | 3.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065040 | 125 | 65 | 4.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065045 | 125 | 65 | 4.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065050 | 125 | 65 | 5.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065055 | 125 | 65 | 5.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065060 | 125 | 65 | 6.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065065 | 125 | 65 | 6.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065070 | 125 | 65 | 7.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065075 | 125 | 65 | 7.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065080 | 125 | 65 | 8.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065085 | 125 | 65 | 8.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065090 | 125 | 65 | 9.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065095 | 125 | 65 | 9.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065100 | 125 | 65 | 10.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065105 | 125 | 65 | 10.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065110 | 125 | 65 | 11.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065115 | 125 | 65 | 11.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065120 | 125 | 65 | 12.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065125 | 125 | 65 | 12.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065130 | 125 | 65 | 13.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065135 | 125 | 65 | 13.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065140 | 125 | 65 | 14.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065145 | 125 | 65 | 14.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ125065150 | 125 | 65 | 15.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110015 | 110 | 110 | 1.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110020 | 110 | 110 | 2.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110025 | 110 | 110 | 2.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110030 | 110 | 110 | 3.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110035 | 110 | 110 | 3.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110040 | 110 | 110 | 4.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110045 | 110 | 110 | 4.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110050 | 110 | 110 | 5.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110055 | 110 | 110 | 5.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110060 | 110 | 110 | 6.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110065 | 110 | 110 | 6.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110070 | 110 | 110 | 7.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110075 | 110 | 110 | 7.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110080 | 110 | 110 | 8.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110085 | 110 | 110 | 8.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110090 | 110 | 110 | 9.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110095 | 110 | 110 | 9.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110100 | 110 | 110 | 10.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110105 | 110 | 110 | 10.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110110 | 110 | 110 | 11.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110115 | 110 | 110 | 11.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110120 | 110 | 110 | 12.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110125 | 110 | 110 | 12.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110130 | 110 | 110 | 13.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110135 | 110 | 110 | 13.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110140 | 110 | 110 | 14.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110145 | 110 | 110 | 14.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ110110150 | 110 | 110 | 15.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105060 | 105 | 105 | 6.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105065 | 105 | 105 | 6.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105070 | 105 | 105 | 7.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105075 | 105 | 105 | 7.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105080 | 105 | 105 | 8.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105085 | 105 | 105 | 8.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105090 | 105 | 105 | 9.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105095 | 105 | 105 | 9.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105100 | 105 | 105 | 10.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105105 | 105 | 105 | 10.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105110 | 105 | 105 | 11.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105115 | 105 | 105 | 11.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105120 | 105 | 105 | 12.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105125 | 105 | 105 | 12.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105130 | 105 | 105 | 13.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105135 | 105 | 105 | 13.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105140 | 105 | 105 | 14.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105145 | 105 | 105 | 14.5 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105150 | 105 | 105 | 15.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105160 | 105 | 105 | 16.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105180 | 105 | 105 | 18.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105200 | 105 | 105 | 20.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105220 | 105 | 105 | 22.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105230 | 105 | 105 | 23.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105240 | 105 | 105 | 24.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105250 | 105 | 105 | 25.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105260 | 105 | 105 | 26.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105270 | 105 | 105 | 27.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105280 | 105 | 105 | 28.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105290 | 105 | 105 | 29.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105300 | 105 | 105 | 30.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105320 | 105 | 105 | 32.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105340 | 105 | 105 | 34.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105350 | 105 | 105 | 35.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105360 | 105 | 105 | 36.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105380 | 105 | 105 | 38.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105400 | 105 | 105 | 40.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105420 | 105 | 105 | 42.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105440 | 105 | 105 | 44.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105450 | 105 | 105 | 45.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105460 | 105 | 105 | 46.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105480 | 105 | 105 | 48.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105500 | 105 | 105 | 50.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105520 | 105 | 105 | 52.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105540 | 105 | 105 | 54.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105550 | 105 | 105 | 55.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105560 | 105 | 105 | 56.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105580 | 105 | 105 | 58.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105600 | 105 | 105 | 60.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105620 | 105 | 105 | 62.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105640 | 105 | 105 | 64.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105650 | 105 | 105 | 65.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105660 | 105 | 105 | 66.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105680 | 105 | 105 | 68.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ105105700 | 105 | 105 | 70.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ150150200 | 150 | 150 | 20.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ150150210 | 150 | 150 | 21.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ150150220 | 150 | 150 | 22.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ150150230 | 150 | 150 | 23.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ150150240 | 150 | 150 | 24.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ150150250 | 150 | 150 | 25.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ150150270 | 150 | 150 | 27.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ150150280 | 150 | 150 | 28.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ150150290 | 150 | 150 | 29.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ150150300 | 150 | 150 | 30.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ150150350 | 150 | 150 | 35.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ150150400 | 150 | 150 | 40.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ150150450 | 150 | 150 | 45.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ150150500 | 150 | 150 | 50.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ150150550 | 150 | 150 | 55.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ150150600 | 150 | 150 | 60.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ150150650 | 150 | 150 | 65.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ150150700 | 150 | 150 | 70.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ205205150 | 205 | 205 | 15.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ205205160 | 205 | 205 | 16.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ205205170 | 205 | 205 | 17.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ205205180 | 205 | 205 | 18.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ205205190 | 205 | 205 | 19.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ205205200 | 205 | 205 | 20.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ205205210 | 205 | 205 | 21.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ205205220 | 205 | 205 | 22.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ205205230 | 205 | 205 | 23.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ205205240 | 205 | 205 | 24.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ205205250 | 205 | 205 | 25.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ205205270 | 205 | 205 | 27.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ205205280 | 205 | 205 | 28.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ205205290 | 205 | 205 | 29.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ205205300 | 205 | 205 | 30.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ205205350 | 205 | 205 | 35.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ255255150 | 255 | 255 | 15.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ255255160 | 255 | 255 | 16.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ255255170 | 255 | 255 | 17.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ255255180 | 255 | 255 | 18.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ255255190 | 255 | 255 | 19.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ255255200 | 255 | 255 | 20.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ255255210 | 255 | 255 | 21.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ255255220 | 255 | 255 | 22.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ255255230 | 255 | 255 | 23.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ255255240 | 255 | 255 | 24.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ255255250 | 255 | 255 | 25.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ255255270 | 255 | 255 | 27.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ255255280 | 255 | 255 | 28.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ255255290 | 255 | 255 | 29.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ255255300 | 255 | 255 | 30.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ255255350 | 255 | 255 | 35.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ300300150 | 300 | 300 | 15.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ300300160 | 300 | 300 | 16.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ300300170 | 300 | 300 | 17.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ300300180 | 300 | 300 | 18.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ300300190 | 300 | 300 | 19.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ300300200 | 300 | 300 | 20.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ300300210 | 300 | 300 | 21.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ300300220 | 300 | 300 | 22.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ300300230 | 300 | 300 | 23.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ300300240 | 300 | 300 | 24.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ300300250 | 300 | 300 | 25.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ300300270 | 300 | 300 | 27.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ300300280 | 300 | 300 | 28.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ300300290 | 300 | 300 | 29.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| BJ300300300 | 300 | 300 | 30.0 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

Ring Series Description

The Ring Series carbide plate is a specialized type of carbide plate designed for various applications in the manufacturing industry. This carbide plate is shaped in a ring-like structure, making it ideal for specific machining and tooling needs.

The Ring Series carbide plate offers exceptional hardness, wear resistance, and strength, ensuring durability and reliability in demanding industrial environments. Its unique ring shape allows for efficient and precise machining operations, such as milling, turning, or grinding, where a circular or curved cutting path is required.

| Part No. | D/mm | d/mm | H/mm | Grade (click here) |

|---|---|---|---|---|

| RRJ075035030 | 75 | 35 | 30 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| RRJ075050070 | 75 | 50 | 70 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| RRJ080018050 | 80 | 18 | 50 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| RRJ080036050 | 80 | 36 | 50 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| RRJ080055050 | 80 | 55 | 50 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| RRJ090030070 | 90 | 30 | 70 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| RRJ100065040 | 100 | 65 | 40 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| RRJ110072050 | 110 | 72 | 50 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| RRJ120075040 | 120 | 75 | 40 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| RRJ130063045 | 130 | 63 | 45 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| RRJ130072045 | 130 | 72 | 45 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| RRJ140073045 | 140 | 73 | 45 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| RRJ140080045 | 140 | 80 | 45 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| RRJ150088030 | 150 | 88 | 30 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| RRJ150120030 | 150 | 120 | 30 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| RRJ160090050 | 160 | 90 | 50 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| RRJ170132035 | 170 | 132 | 35 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

| RRJ200140040 | 200 | 140 | 40 | TC2406, TF1113A, TF1113B, TM1513, TF1312, TM1512, TM2214, TC2515 |

- Contact

Our team is ready to provide support

Truer Carbide is committed to providing efficient solutions to problems. Each team member has the expertise and experience to quickly understand and meet your needs.