- Carbide grades

Standard Carbide Grade Offerings

Grades are a way to classify different make ups of cobalt, tungsten carbide and some other dopings within a tungsten carbide product. Tungsten carbide, also called as cemented carbide, which is a composite material consisting of particles of tungsten carbide bonded or cemented together in a matrix of a metallic element of a lower melting point, such as cobalt or nickel. The process of powder metallurgy is skillfully employed to produce cemented carbides.

We offer a vast array of tungsten carbide grades from nanoscale to extra-coarse grain size with various of shapes. When required by your application, we also can supply a custom-blended grade formula that best fit your needs based on cobalt content, grain size, hardness and toughness (represented by transverse rupture strength (TRS) per ISO3327) requirements. Our customer service and metallurgical support groups are always available and prepared to discuss your specific needs. Contact us if you have any questions about specific grades and their applications.

Carbide Grade properties

| Grade | ISO Code | Grain Size {um} | Cobalt Content {wt%} | Density{g/cm³} | Hardness {HRA} | TRS {N/mm²} |

|---|---|---|---|---|---|---|

| TS710 | K20-K30 | 0.7 | 10.0 | 14.45 | 91.8 | 3800 |

| TS610 | K20-K30 | 0.6 | 10.0 | 14.45 | 92.2 | 4000 |

| TU412 | K30-K40 | 0.4 | 12.0 | 14.12 | 92.5 | 4200 |

| TU409 | K10-K20 | 0.4 | 9.0 | 14.50 | 93.2 | 4000 |

| TU406 | K05-K10 | 0.4 | 6.0 | 14.8 | 94.1 | 3800 |

| TN209 | K20-K30 | 0.2 | 9.0 | 14.45 | 94.0 | 4200 |

| TS715 | K30-K40 | 0.7 | 15.0 | 13.98 | 89.0 | 4500 |

| TU408 | K10-K20 | 0.4 | 8.5 | 14.52 | 93.5 | 3800 |

| TU510 | K20-K40 | 0.5 | 10.3 | 14.30 | 92.3 | 4200 |

| TU512A | K20-K40 | 0.5 | 12.0 | 14.10 | 92.0 | 4200 |

| TU512B | K20-K40 | 0.5 | 12.0 | 14.10 | 91.2 | 4500 |

| TS606 | K10 | 0.6 | 6.0 | 14.90 | 93.3 | 3800 |

| TS613 | K30-K40 | 0.6 | 13.5 | 14.08 | 90.5 | 4000 |

| TM1512 | K30-K40 | 1.0-2.0 | 12.5 | 14.10 | 89.5 | 3600 |

| TM2214 | K40-K50 | 1.5-3.0 | 14.0 | 14.00 | 88.5 | 3700 |

| TC2406 | 0.8-4.0 | 6.0 | 14.80 | 90.5 | 2900 | |

| TF1113A | 0.8-1.5 | 13.0 | 14.20 | 90.0 | 3000 | |

| TF1113B | 0.8-1.5 | 13.5 | 14.00 | 90.0 | 3600 | |

| TM1513 | 1.0-2.0 | 13.0 | 14.20 | 89.5 | 3800 | |

| TF1312 | 0.8-1.8 | 12.0 | 14.30 | 90.0 | 3500 | |

| TC2515 | 1.0-4.0 | 15.0 | 13.90 | 87.5 | 3500 |

Comment:

The classification of tungsten carbides according to grain size corresponds to the recommendations of the Powder Metallurgy association.

The performance of carbide rods are determined by hardness and transverse rupture strength. With regard to their application, these characteristics can be optimized by the cobalt content percentage and the grain size of tungsten carbides.

| Average grain size [um] | Classification |

|---|---|

| < 0.2 | nano |

| 0.2 – < 0.5 | ultrafine |

| 0.5 – < 0.8 | submicron |

| 0.8 – < 1.3 | fine |

| 1.3 – < 2.5 | medium |

| 2.5 – < 6.0 | coarse |

| > 6.0 | extra – coarse |

Grades for Carbide Buttons of Mining and Construction

| Grade | ISO Code | Grain Size | Density {g/cm³} | Hardness {HRA} | TRS {N/mm} | Application Recommendation |

|---|---|---|---|---|---|---|

| Grade for Mining, Coal Mining and Construction | ||||||

| TM28 | K20 | Medium | 15.00 | 90.3 | 2800 | Exellent balance of impact & wear resistance. suitable for cemented carbide buttons of DTH bits and threaded drilling bits. |

| TM28N | K20 | Medium | 15.00 | 90.0 | 2850 | |

| TM25 | K20 | Medium | 15.00 | 90.2 | 2500 | |

| TC26 | K20 | Coarse | 14.90 | 89.2 | 2600 | |

| TC24 | K30 | Coarse | 14.70 | 88.5 | 2400 | Mainly used for carbide buttons of tricone bits and inserts of other dirlling bits. |

| TC26 | K30 | Coarse | 14.50 | 88.0 | 2600 | |

| TC27 | K40 | Coarse | 14.45 | 87.0 | 2700 | Suitable for carbide inserts of heavy-duty rock drilling tools, also for tricone bits. |

| TEC28 | K30 | Extra-coarse | 14.50 | 87.0 | 2800 | Extra-coarse grain size, with high impact resistance, special for mining, road milling and pile foundation. |

| TEC30A | K40 | Extra-coarse | 14.40 | 86.5 | 3000 | |

| TEC30N | K40 | Extra-coarse | 14.35 | 86.3 | 3000 | |

| TEC30B | K40 | Extra-coarse | 14.30 | 86.2 | 3000 | |

| TEC26N | K30 | Extra-coarse | 14.90 | 86.5 | 2600 | |

| TEC28N | K30 | Extra-coarse | 14.70 | 86.0 | 2800 | |

| Grade for Oil field and PDC | ||||||

| YG8 | K30 | Medium | 14.75 | 90.0 | 2400 | Good wear resistance, suitable for diameter-keeping & serrated inserts. |

| YG11C | K40 | Coarse | 14.40 | 88.0 | 2600 | Good impact resistance, suitable for midium-hard or soft rock application. |

| YG13C | K40 | Coarse | 14.20 | 87.0 | 2600 | |

| TM28NB | K50 | Medium | 14.20 | 87.5 | 2800 | Good impact and wear resistance, suitable for composite with PDC and PCBN. |

| YG13 | K40 | Medium | 14.20 | 87.5 | 2800 | |

| YG16 | K50 | Medium | 13.90 | 87.0 | 2900 | Super impact resistance, suitable for composite with diamond excavation in oil field |

| TM30 | K50 | Medium | 13.90 | 86.5 | 3000 | |

Grades for Tungsten Carbide Saw Tips

| Grade | ISO Code | Grain Size | Density {g/cm³} | Hardness {HRA} | TRS {N/mm} | Application Recommendation |

|---|---|---|---|---|---|---|

| General Grades | ||||||

| YG6 | K20 | Medium | 14.85-15.05 | 91.0 | 2100 | For ordinary wood |

| YG8 | K30 | Medium | 14.60-14.85 | 90.0 | 2400 | For ordinary wood, also for aluminium |

| TC24S | K40 | Coarse | 14.50-14.80 | 88.5 | 2400 | For recycling wood, especially wood with some nails and stones |

| TM22 | K20 | Medium | 14.65-14.85 | 91.0 | 2200 | For hard wood, also for aluminium alloys |

| YG6X | K10 | Fine | 14.75-14.95 | 92.0 | 2000 | Specially for wood |

| YG8X | K10 | Fine | 14.60-14.85 | 91.5 | 2200 | For both wood and aluminium alloys |

| High-perperties Grades | ||||||

| TF30 | K10 | Fine | 14.70-14.85 | 92.0 | 3000 | Specially for hard wood |

| TF24 | K10 | Fine | 14.80-15.05 | 92.2 | 2400 | Specially for hard wood |

| TF30A | K20 | Fine | 14.60-14.80 | 91.5 | 3000 | Specially for aluminium alloys |

| TS30C | K05 | Submicron | 14.70-14.95 | 93.2 | ≥3000 | For high density wood and aluminium-plastic composite |

| TS30A | K10 | Submicron | 14.50-14.80 | 92.5 | ≥3000 | Specially for aluminium alloys |

| TS30S | K10 | Submicron | 14.25-14.55 | 92.0 | ≥3050 | For stone and aluminium alloys |

| TS20-1 | K10 | Submicron | 15.20-15.35 | 95.5 | ≥2000 | For plywood, density board and sandwich board |

| TS20-2 | K10 | Submicron | 15.10-15.25 | 95.5 | ≥2000 | For plywood, density board and sandwich board |

| TS20-3 | K01 | Submicron | 15.00-15.20 | 95.0 | ≥2000 | For particle board, laminated board, density board, and composite material |

| TS20-4 | K01 | Submicron | 14.90-15.10 | 94.5 | ≥2000 | For particle board, laminated board, density board, and composite material |

| TS24 | K10 | Submicron | 14.70-14.85 | 94.0 | ≥2400 | For plywood, density board and sandwich board |

| TS26 | K05 | Submicron | 14.90-15.10 | 93.6 | ≥2600 | For particle board, laminated board, density board, and composite material |

| TM22H | P40 | Medium | 12.80-13.30 | 90.0 | ≥2200 | For large saw blades |

| TM21 | M30 | Medium | 12.70-13.30 | 91.0 | ≥2100 | For the sawing of steels and stainless steels |

| TM20 | M20 | Medium | 12.85-13.35 | 91.5 | ≥2050 | For the sawing of cast iron and steel plates |

Grades for Carbide Brazed Cutting Tips

| Grade | Density {g/cm³} |

Hardness {HRA} |

TRS {N/mm²} |

ISO Code | Application Recommendation |

|---|---|---|---|---|---|

| K10UF | 14.70-14.95 | ≥93.0 | ≥3000 | K05 | Suitable for the finishing of cast iron and nonferrous metal. |

| YG3X | 15.00-15.20 | ≥92.5 | ≥1300 | ||

| YG3 | 15.15-15.30 | ≥91.5 | ≥1400 | ||

| YG6X | 14.70-14.85 | ≥91.7 | ≥1860 | K10 | Suitable for the finishing & semi-finishing of cast iron and nonferrous metals, and also for the machining of manganese steel and hardening steel. |

| YG6A | 14.85-15.05 | ≥92.0 | ≥1600 | ||

| YG6 | 14.85-15.05 | ≥90.5 | ≥1860 | K20 | Suitable for the roughing of cast iron and light alloys, ans also for milling of cast iron and low-alloy steel. |

| YG8 | 14.60-14.85 | ≥89.7 | ≥2060 | K30 | |

| YS8 | 13.70-14.10 | ≥92.5 | ≥1720 | M05 | For the finishing of iron-based & nickel-based high-temperature alloys, high-strength steels, chilled cast iron, heat resistant stainless steel, high manganese steel and hardened steel. |

| YW1 | 13.00-13.30 | ≥92.0 | ≥1600 | M10 | For the finishing and semi-finishing of stainless steel and common alloy steels. |

| YS2T | 14.25-14.55 | ≥91.0 | ≥2160 | ||

| YT03 | 14.75-14.95 | ≥91.5 | ≥1860 | ||

| YW2 | 12.90-13.30 | ≥91.0 | ≥1680 | M20 | For the semi-finishing of stainless steel and low-alloy steel, mainly for the machining of railway wheel hubs. |

| YW5 | 12.90-13.30 | ≥90.5 | ≥1680 | ||

| YT15 | 11.10-11.50 | ≥91.5 | ≥1600 | P10 | For the finishing & semi-finishing of steel and cast steel with a moderate feed rate and a rather high cutting speed. |

| YT14 | 11.20-11.60 | ≥91.0 | ≥1680 | P20 | For the finishing & semi-finishing of steel and cast steel with a moderate feed rate, and YS25 specially used for the milling of steel and cast steel. |

| YS25 | 12.80-13.20 | ≥90.5 | ≥2060 | ||

| YT5 | 12.60-13.00 | ≥90.0 | ≥1750 | P30 | For the heavy duty rough turning of steel and cast steel under unfavorable working conditions with a high feed rate, and YC30S specially for the milling of steel and cast steel. |

| YC30S | 12.80-13.00 | ≥89.5 | ≥1600 | ||

| YC40 | 12.80-13.30 | ≥89.5 | ≥1700 | P40 | For the heavy duty rough turning of steel and cast steel with a high feed rate, and also for face milling. |

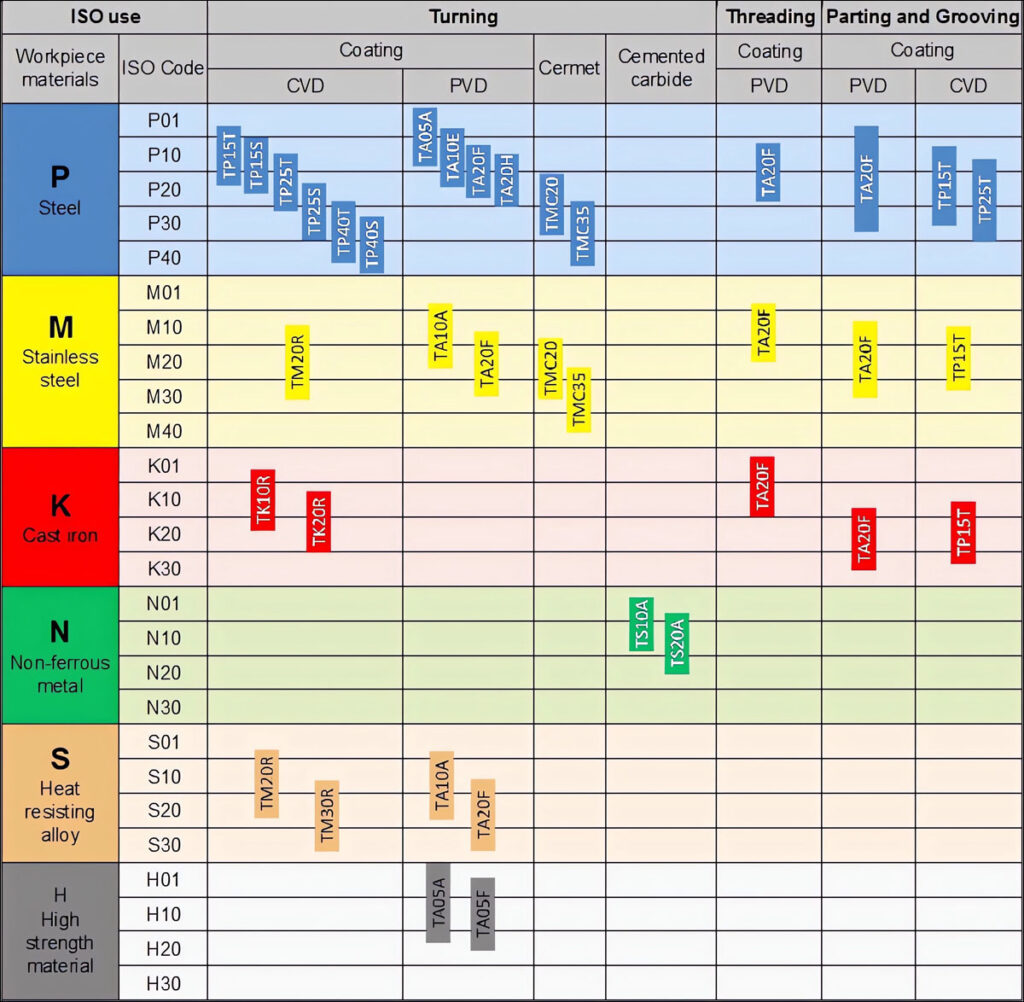

Recommended Grade for Turning Inserts

Fracture Toughness Vs Hardness

Grade application

| ISO Letter | Workpiece | TN209 | TU406 | TU409 | TU412 | TS610 | TS710 | TS715 | |

|---|---|---|---|---|---|---|---|---|---|

| P | Steel | Roughing | |||||||

| Finishing | |||||||||

| M | Stainless steel | Roughing | |||||||

| Finishing | |||||||||

| K | Cast iron | Roughing | |||||||

| Finishing | |||||||||

| N | Non-ferrous metals | Roughing | |||||||

| Finishing | |||||||||

| S | Heat resistant alloys | Roughing | |||||||

| Finishing | |||||||||

| H | Hard materials | Roughing | |||||||

| Finishing | |||||||||

| Impact & vibration resistant application | |||||||||

We can supply customers with a broad variety of tungsten carbide products, including carbide blanks, semifinished products & some preforms with different shapes and dimensions, such as carbide rods, carbide plates, carbide strips, carbide cutting tools and carbide saw tips, button bits, reamers, blades, inserts, balls & burrs for the applications of mining, construction, oil & gas, energy industry etc.

We provide a comprehensive inventory of grades and sizes for quick availability.